Window type solar plastic heat collector

A technology of solar heat collectors and plastics, which is applied in the direction of solar heat collectors, solar thermal energy, and solar heat collectors using working fluids. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

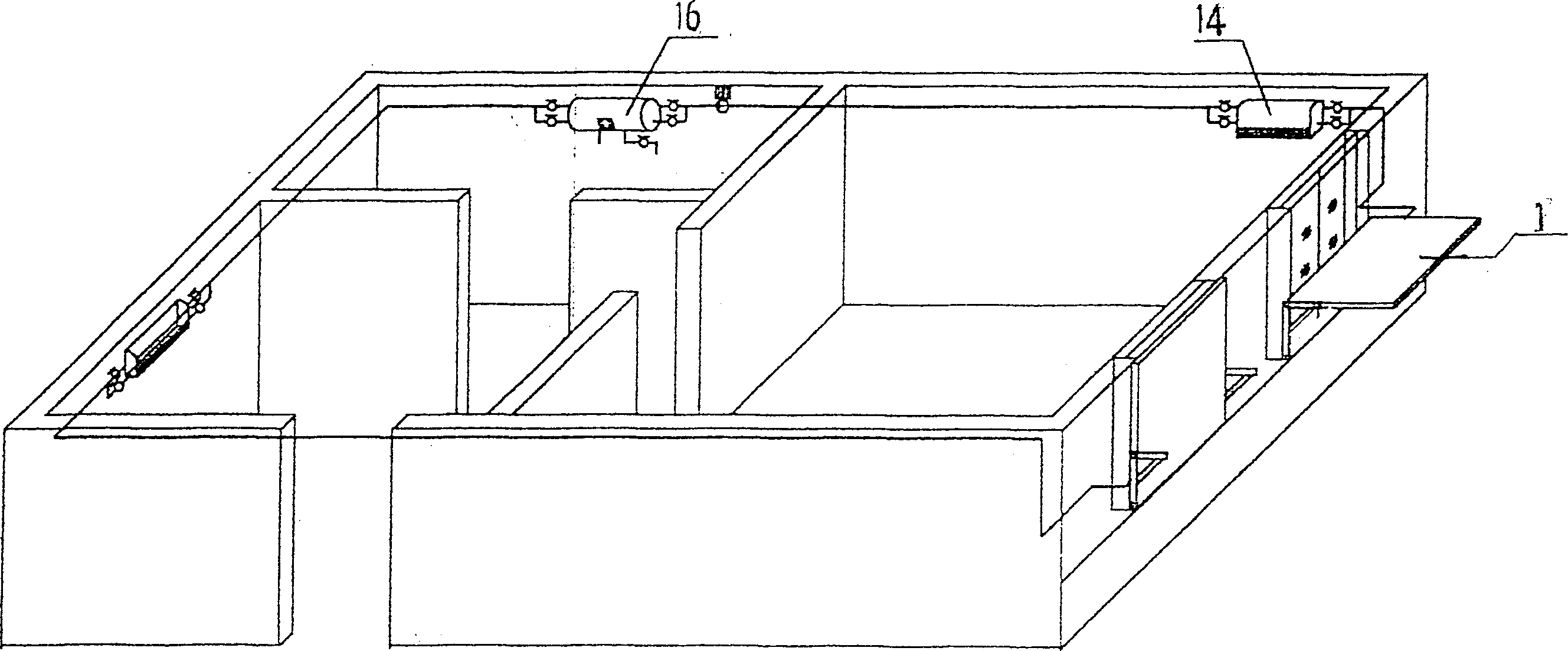

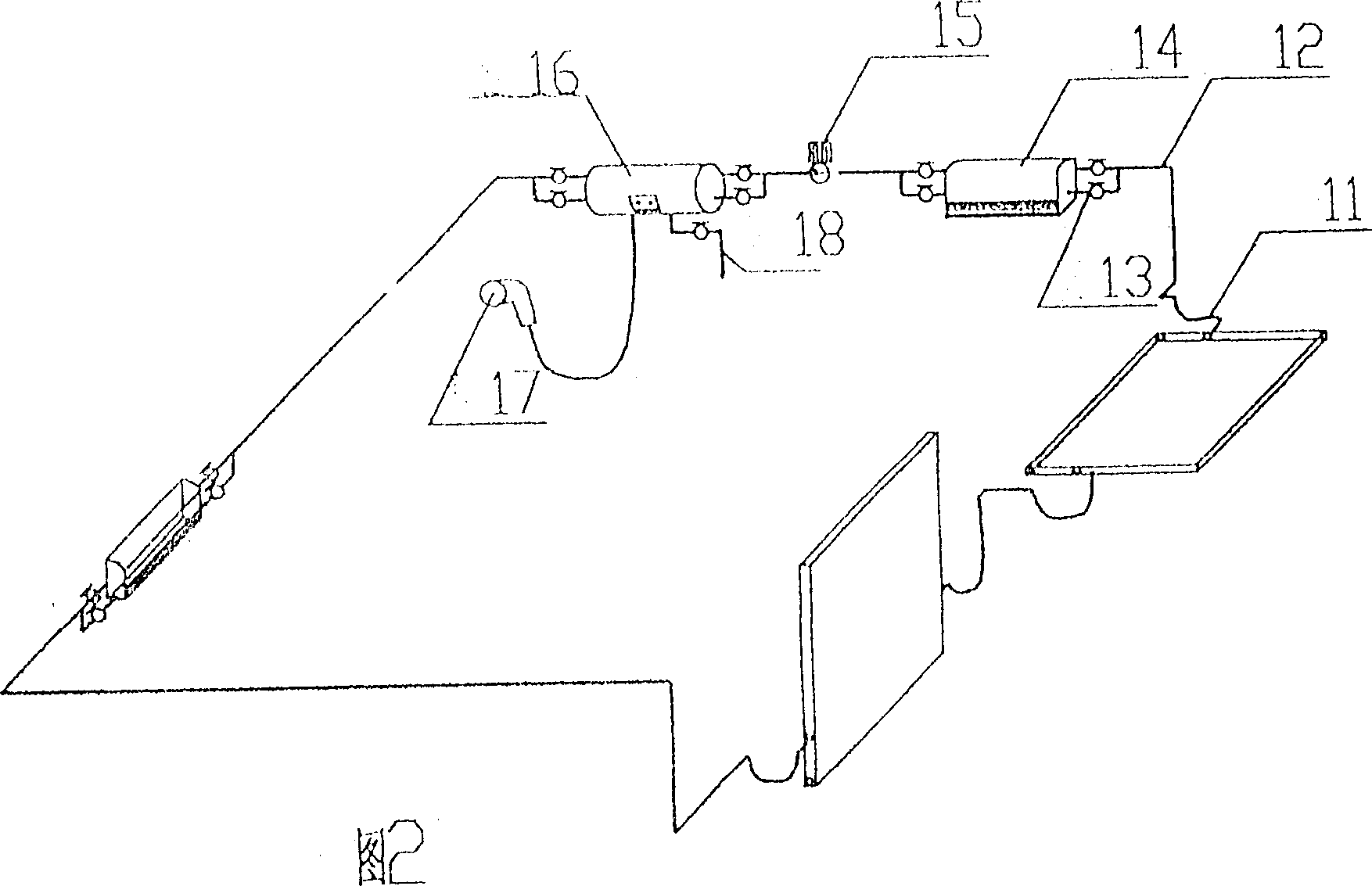

[0017] Reference attached figure 1 , 2. The heat collecting plate 1 of the window-type plastic solar collector is installed in front of the outdoor glass window, placed horizontally, connected to the indoor pipeline through the water outlet 1-9, the flexible water pipe 11, and the regulating valve 13 and the radiator 14. The water pump 15 and the water storage tank 16 are returned to the heat collecting plate 1 through the pipeline to form a circulation cycle. When taking a bath, the shower nozzle 17 sprays water and the water supply pipe 18 supplies water.

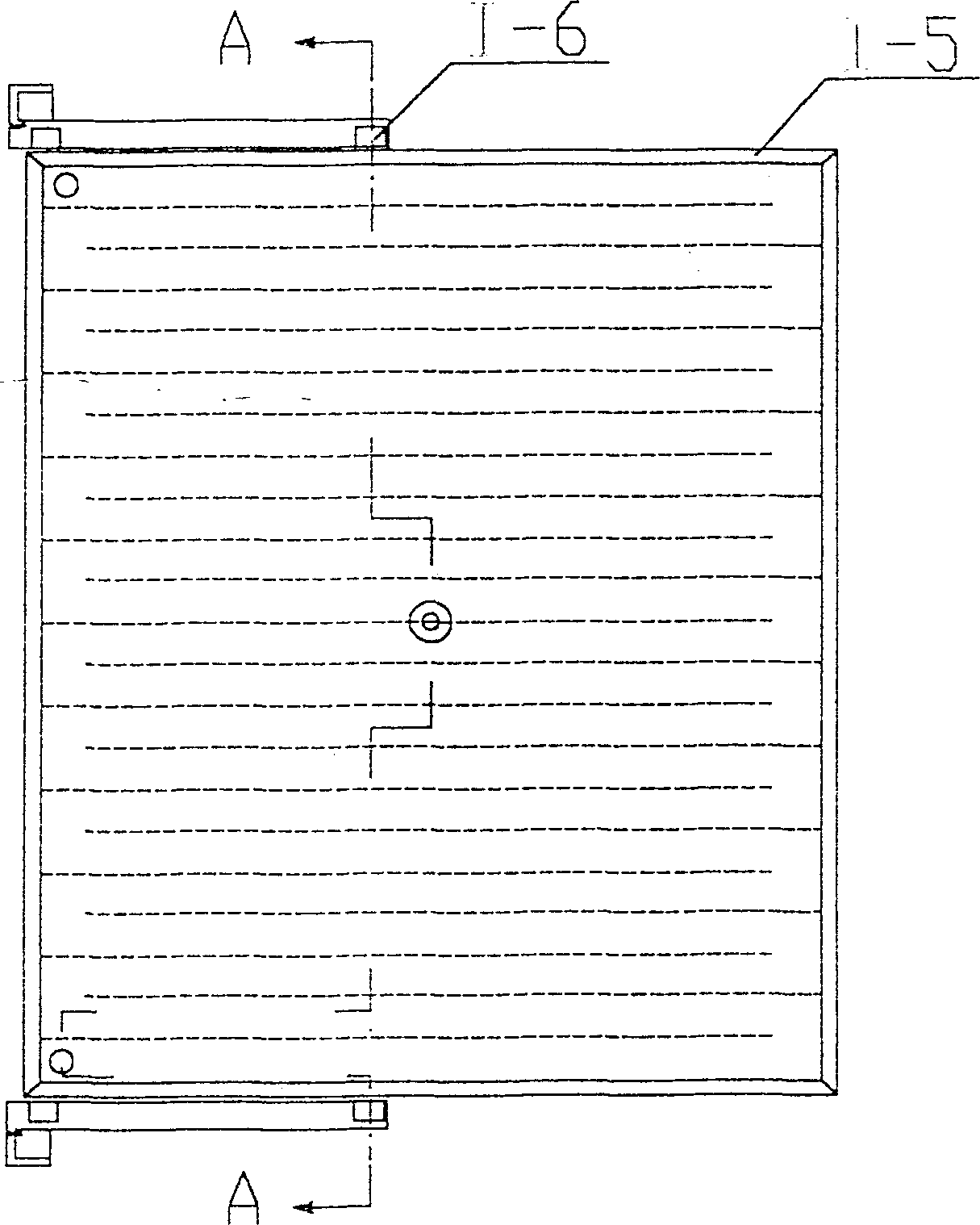

[0018] Reference attached image 3 , 4, the heat collecting plate of the window-type plastic solar collector is made of polymer materials; the supporting frame 1-5, the transparent partition 1 of the negative pressure cavity formed by the light-transmitting plate 1-1 and the light-transmitting partition 1-2 -2 and the graphite circulating water channel plate 1-3 constitute a water flow chamber, and the foam insulation layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com