Preparation method of zinc oxide UV photodetector prototype device

A technology of electrical detectors and ultraviolet light, which is applied in photometry, electrical solid devices, electrical components, etc., can solve the problems of ZnO film surface corrosion and affect device performance, and achieve the effect of compact bonding and preventing device performance from deteriorating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment further illustrate the present invention.

[0015] The inventive method comprises the following steps successively:

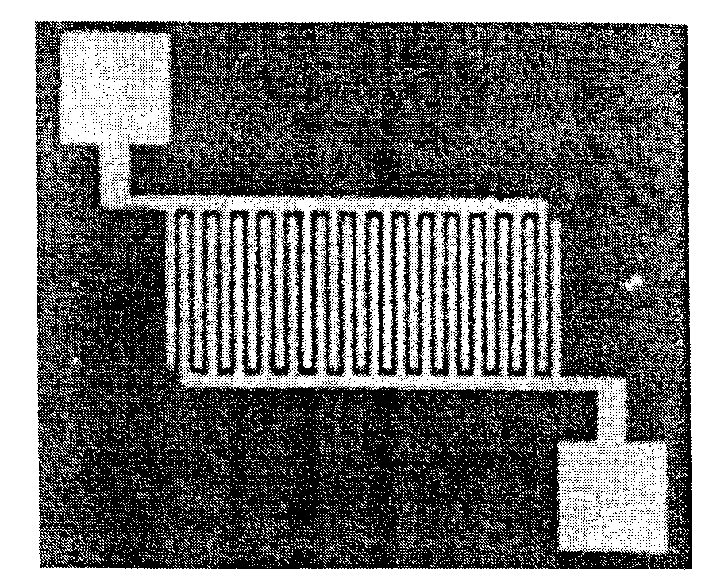

[0016] 1. Spin-coat a photoresist with a thickness of 1 micron on the surface of the ZnO film, and engrave interdigitated electrodes (as shown in Figure 1) in one photolithography process. Except for the electrode pattern, the rest is still covered with a photoresist coating;

[0017] 2. Deposit metal aluminum directly on the sample after photolithography by magnetron sputtering, and control the thickness of the metal aluminum layer to 0.3 microns.

[0018] 3. Put the ZnO thin film covered with metal aluminum in an acetone solution for ultrasonic cleaning, wash off the photoresist and the aluminum layer deposited on the photoresist, and prepare the electrode.

[0019] 4. The sample was annealed at 450°C for 6 minutes under the protection of a nitrogen atmosphere to remove organic contamination on the surface of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com