Bipolar insulated-gate transistor device, its preparing process and method for controlling its switching speed

A bipolar transistor and transistor technology, applied in the field of insulated bipolar gate transistor device and its manufacture, controlling its switching rate, power semiconductor device and its manufacture, can solve the problem of increasing forward voltage drop and leakage current of transistor device, Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

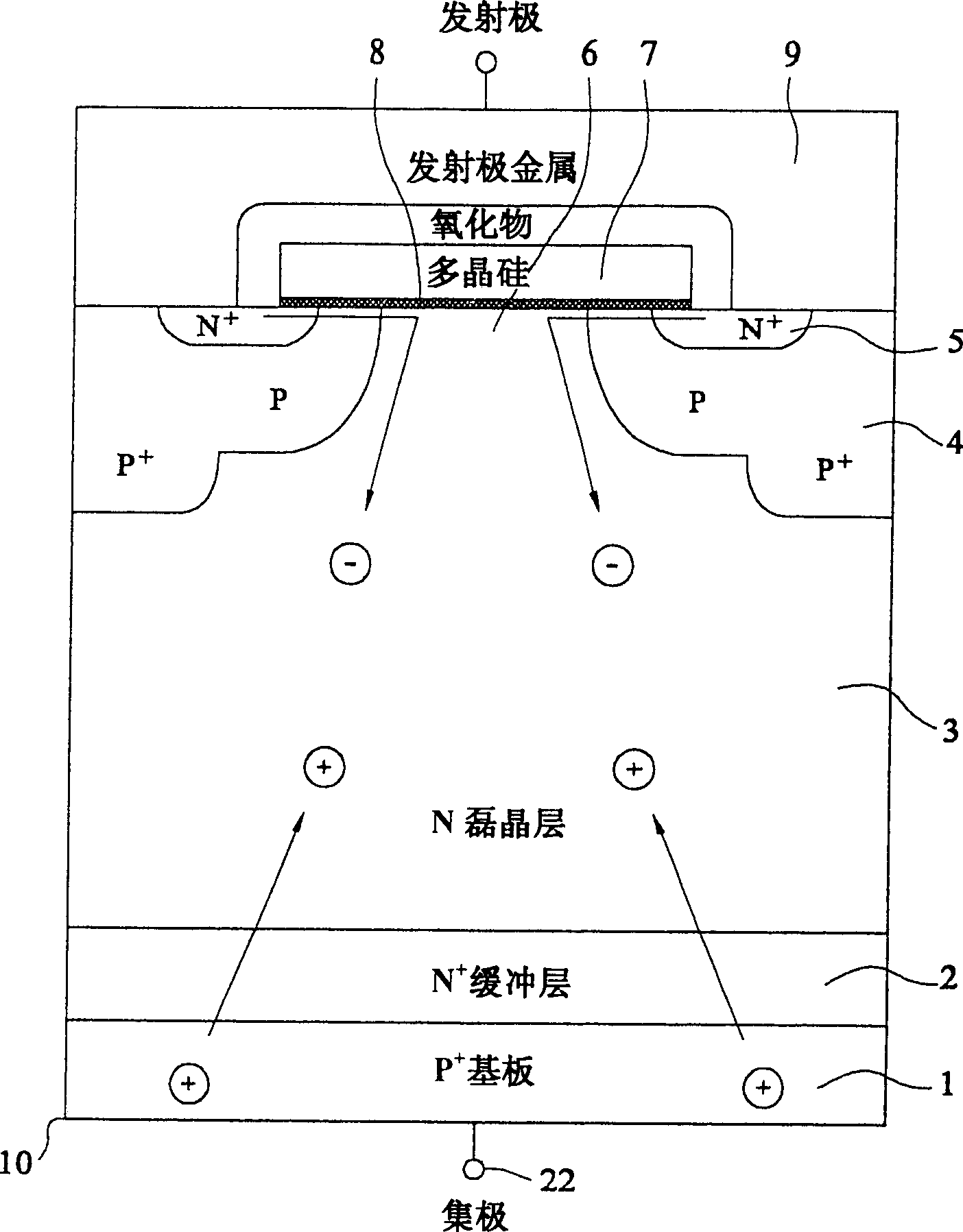

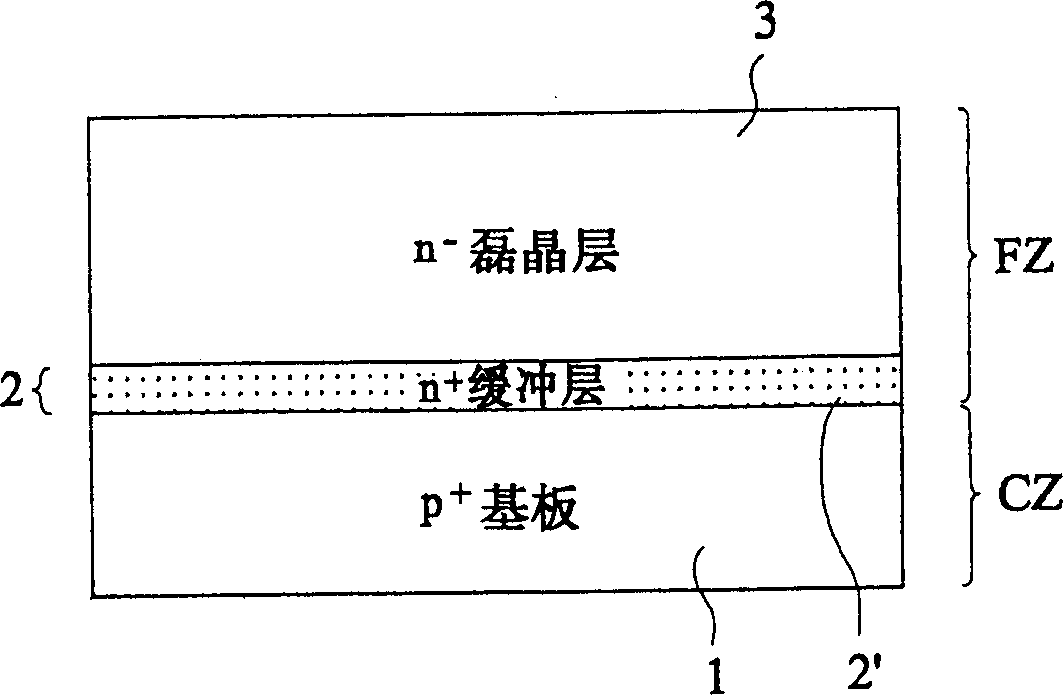

[0026] Such as figure 1 As shown, the present invention provides an IGBT device, wherein a phosphorus-doped n+ buffer layer 2 with a thickness of about 5-12 microns is formed on a p+ silicon substrate 1, and an n+ buffer layer 2 with a thickness of about 60-150 microns -layer 3 is on the n+ buffer layer 2, and the p-type base layer 4 is selectively formed on the upper main surface of the n- epitaxial layer 3, thereby forming a p+ semiconductor layer 1, n-type layer 3 and 2 (n- and n+), and a pnp bipolar transistor of the p-type base layer 4. Further, the n+ emitter region 5 is selectively formed on the upper main surface of the p-type base layer 4; the p-type base region 4 sandwiched by the n-type semiconductor layer 3 and the n+ emitter region 5 The channel region 6 of the upper main surface part is deposited with a gate electrode 7, the gate electrode 7 is a polysilicon structure, and a gate insulating film 8 is contained between the gate electrode 7 and the channel region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com