Radically polymerizable adhesive agent composition, and method for manufacturing electrical connector

A manufacturing method, free radical technology, applied in adhesive heating bonding method, connection, adhesive, etc., can solve the problem of wafer shear strength drop and other problems, and achieve the effect of promoting thermal free radical polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

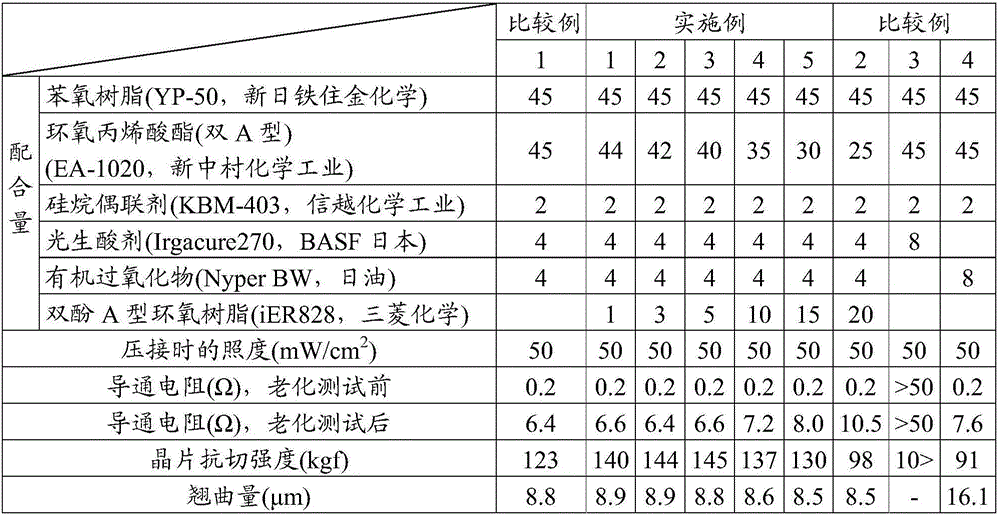

Embodiment 1~5、 comparative example 1~4

[0071] A mixture (adhesive composition) obtained by mixing the components of the composition shown in Table 1 by a conventional method was applied to a release polyester film and dried at 70° C. to obtain a 20 μm thick adhesive sheet.

[0072]

[0073] The obtained adhesive sheet was sandwiched between an IC (outer dimensions: 1.8 mm x 20 mm, bump height 15 μm) as an evaluation substrate and aluminum wire electrodes (light-shielding part ) between ITO-coated glass (glass thickness 0.5mm, ITO thickness 200nm) as the base glass substrate, heat and press the IC under the conditions of crimping temperature 100°C, crimping pressure 80MPa, crimping time 5 seconds, 2 seconds after the start of heating, UV irradiation was carried out for 3 seconds from the back side of the glass substrate (side on which the aluminum wire electrodes were formed) under the UV irradiation conditions (UV light source: UV irradiator ZUV-C30H (Omron Co., Ltd.)) in Table 1, Thus, an electrical connector fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com