Three-dimensional memory and its manufacturing method

A manufacturing method and memory technology, which can be applied to electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of storage and storage cell scaling bottlenecks, limited critical dimensions of planar NAND flash memory, etc., and achieve the effect of improving uniformity and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

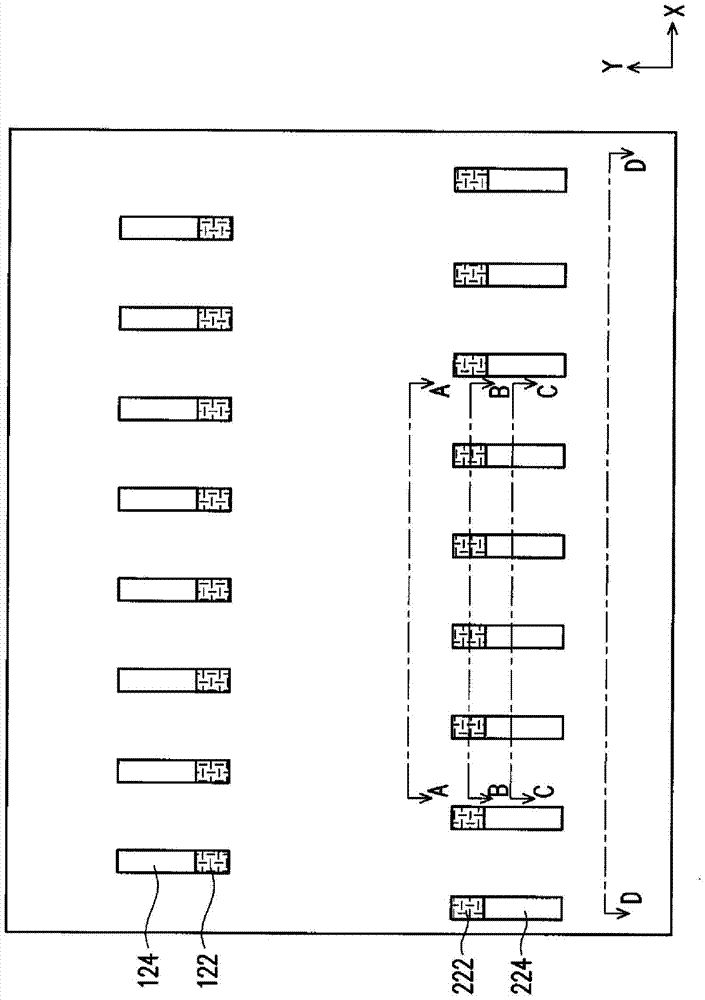

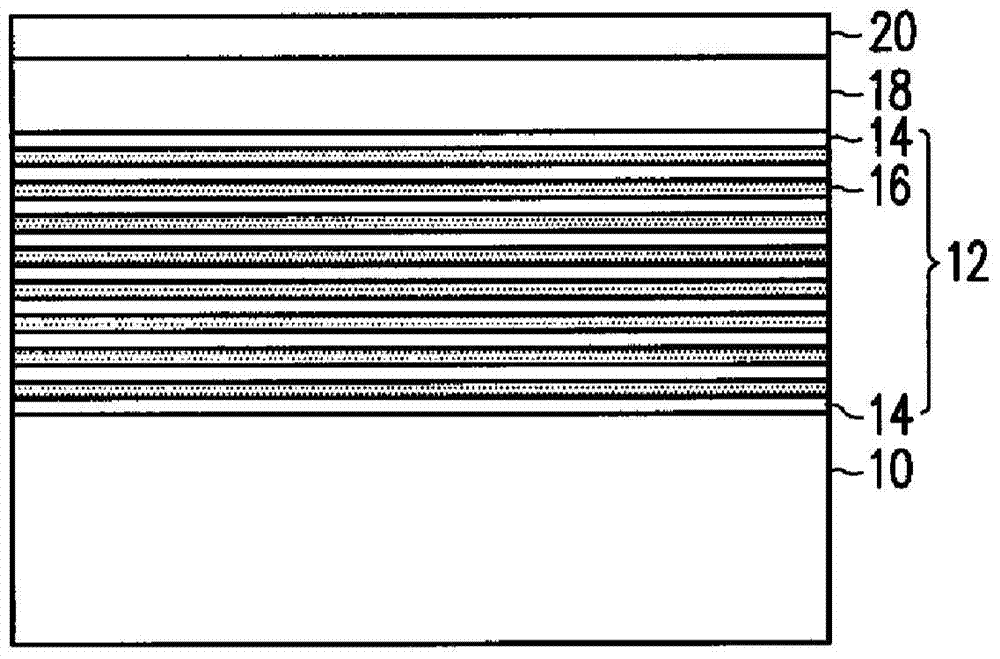

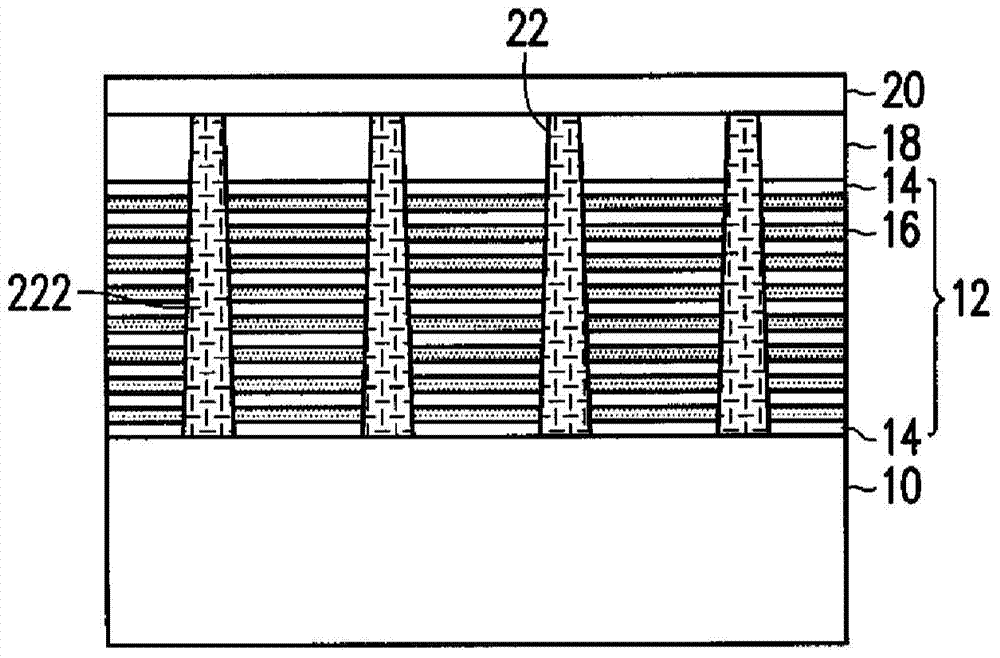

[0050]Figure 1 to Figure 8 is a top view of the flow of a manufacturing method of a three-dimensional memory according to an embodiment of the present invention. Figure 1A to Figure 8A yes Figure 1 to Figure 8 Sectional view of the A-A tangent. Figure 1B to Figure 8B yes Figure 1 to Figure 8 Sectional view of the B-B tangent. Figure 1C to Figure 8C yes Figure 1 to Figure 8 Sectional view of the C-C tangent. Figure 1D to Figure 8D yes Figure 1 to Figure 8 Sectional view of the D-D tangent.

[0051] Please refer to Figure 1 to Figure 1D , forming a stacked structure 12 on the substrate 10 . The stack structure 12 includes a plurality of insulating layers 14 and a plurality of semiconductor layers 16 alternately. The material of the insulating layer 14 may be a dielectric material, such as silicon oxide, silicon nitride, silicon oxynitride or a combination thereof. The thicknesses of the insulating layers 14 can be the same or different, and the thicknesses are, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com