Polymer electrolyte battery and method of producing same

A technology of electrolyte and polymer, applied in the field of polymer electrolyte battery and its manufacturing, can solve the problems of inconvenient adjustment of battery thickness, extremely difficult to obtain curvature, short circuit of laminated electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0109] [production of positive electrode]

[0110] Measure and use 92 parts by weight of LiCoO as the positive electrode active material 2 , 5 parts by weight of powdered graphite as a conductive material and 3 parts by weight of powdered polyvinylidene fluoride as a binder, as components of the positive electrode composition mixture. Then, these components were dispersed into N-methylpyrrolidone to prepare a slurry of a positive electrode composition mixture.

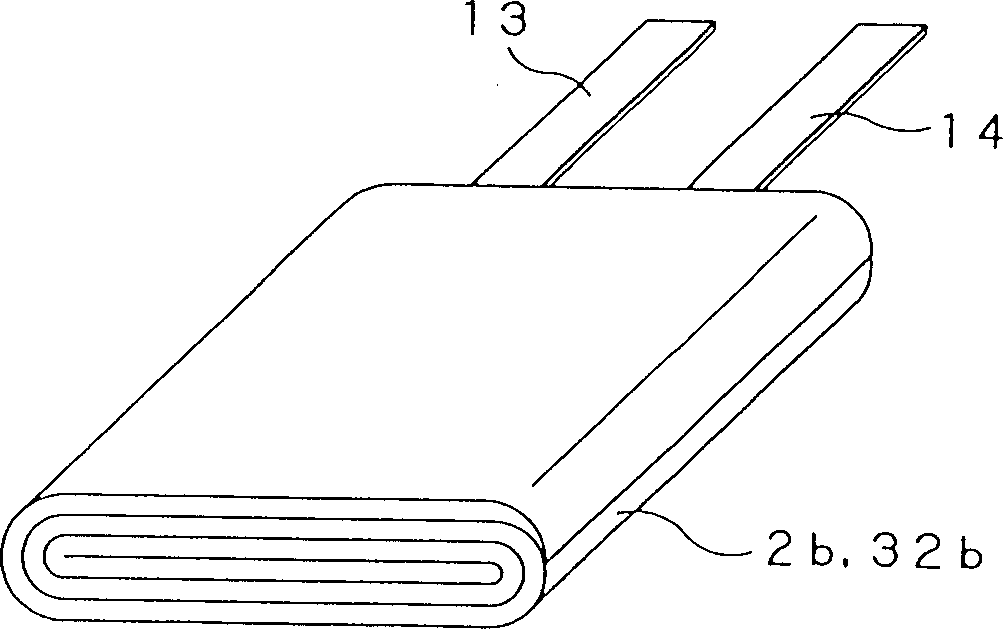

[0111] Then, the prepared positive electrode composition mixture was uniformly coated on both surfaces of a positive electrode current collector made of aluminum foil (20 μm in thickness), and then dried under reduced pressure at a temperature of 100 °C for 24 hours to form Positive electrode active material layer. Thereafter, the positive electrode active material layer was compression molded using a rolling machine to form a positive electrode sheet. Thereafter, the positive electrode sheet was cut to manufacture ...

example 2

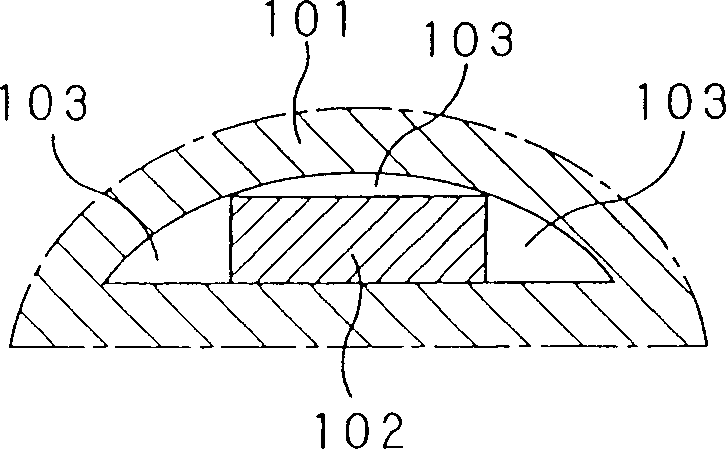

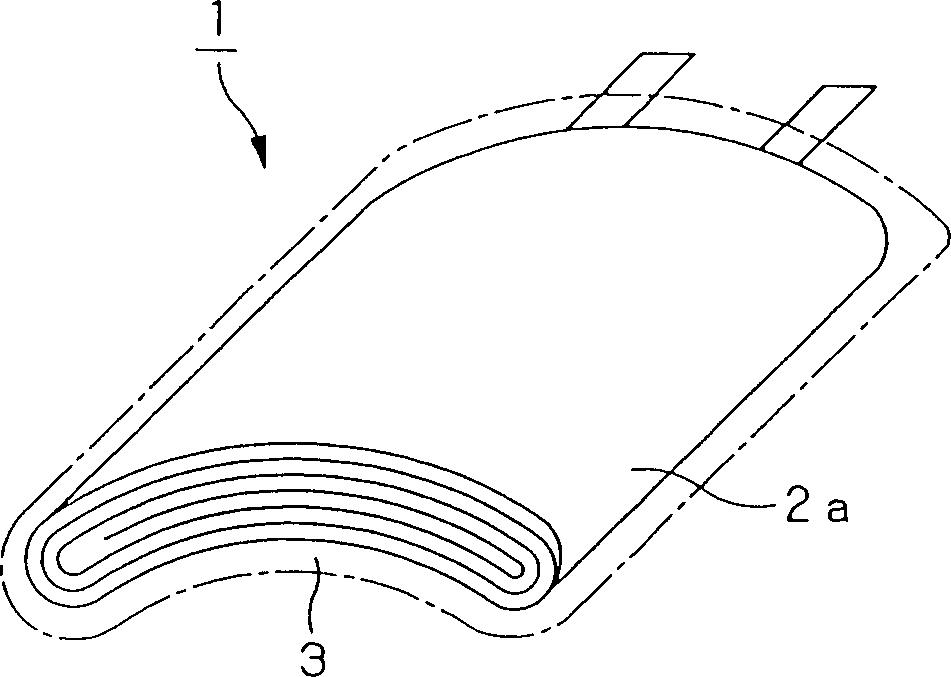

[0123] In addition to using a heat press including a concave heating block and a flat heating block to perform heat compression welding on the flat battery element sealed in the outer packaging film, the polymer electrolyte battery is manufactured in the same way as in Example 1, so that the vertical The cross-section of the battery element on the winding shaft has a substantially semicircular shape.

example 3

[0125] In addition to using a heat press including a concave heating block having a flat portion in the central area of the curved portion, on which a 1 mm thick silicone rubber sheet is adhered, and a convex heating block having a flat portion in the central area of the curved portion , except that the flat-shaped battery sealed in the outer packaging film is subjected to thermocompression welding, a polymer electrolyte battery is manufactured in the same manner as in Example 1, so that the cross section of the battery element perpendicular to the winding axis has a flat portion in at least a part thereof curved shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com