Heat dissipation structure for connector module

A technology of connector module and heat dissipation structure, which is applied in the direction of connection, provision of connectors and printed circuit boards, installation of connection components, etc., can solve the problems of short circuit of control board, increase of heat, easy damage of control board, etc., and improve heat dissipation performance , the effect of reducing the possibility of damage and short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

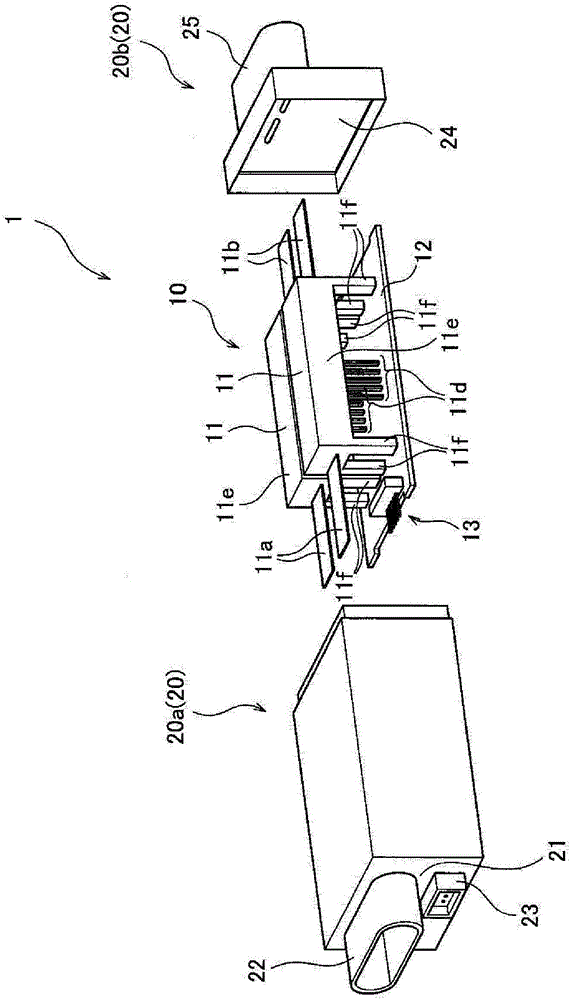

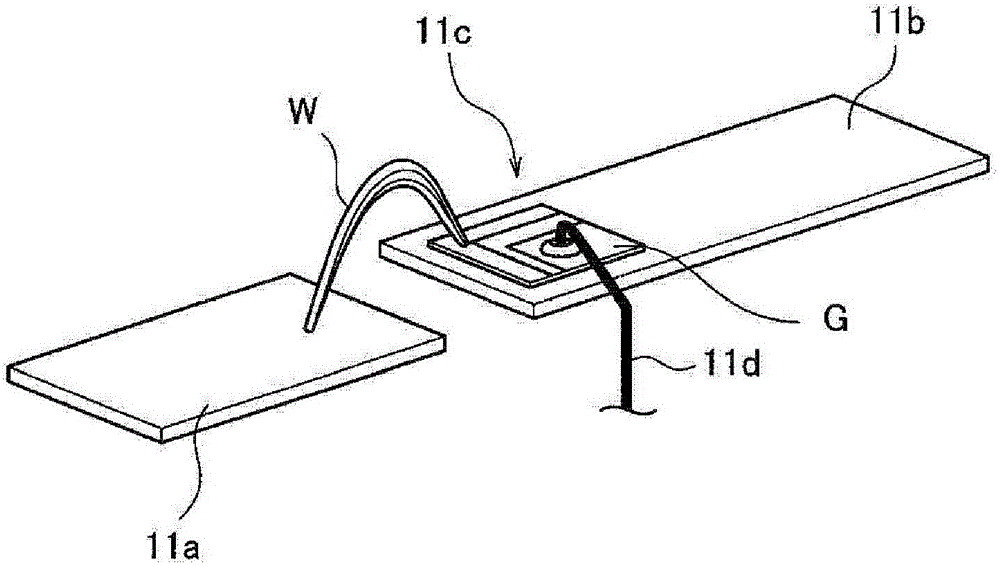

[0098] Exemplary embodiments are described below with reference to the accompanying drawings.

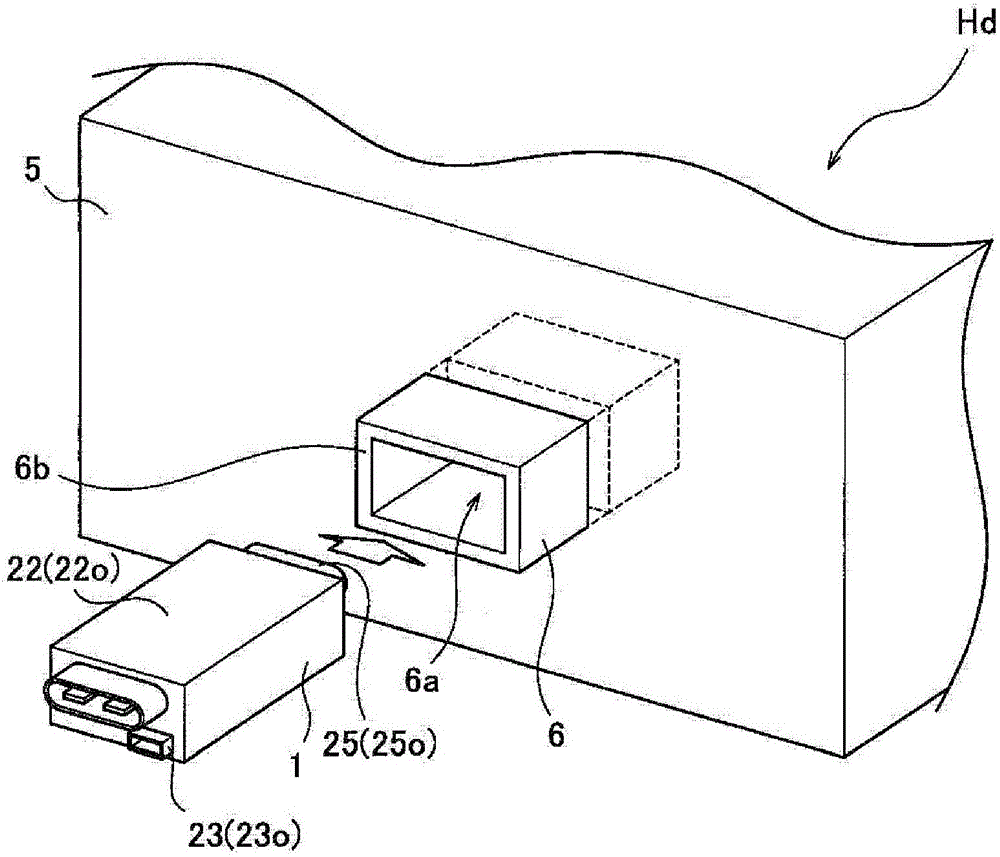

[0099] figure 1 is a perspective view showing the heat dissipation structure for the connector module according to the first embodiment of the present invention. Such as figure 1 As shown, the heat dissipation structure Hd for the connector module 1 is composed of the connector module 1 and the metal case (metal part) 5 . The connector block 1 is provided, for example, on a path through which a large current flows, and contains a heat generating element (see reference numeral 11c described later). The metal case 5 is, for example, a battery case for a high-voltage battery installed in a vehicle.

[0100] A module fixing portion 6 into which the connector module 1 is inserted and fixed is formed in this metal case 5 . Such as figure 1 As shown, the module fixing portion 6 is composed of a rectangular opening 6a and a frame member 6b. The frame member vertically extends from one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com