Prepn and application of titanium silicate adsorbent with high adsorption performance

A titanium silicate, high adsorption technology, applied in chemical instruments and methods, silicon compounds, other chemical processes, etc., can solve the problems of low crush resistance, low dehumidification capacity, and high regeneration temperature, and achieve reduced wear rate and desorption. The effect of fast speed and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

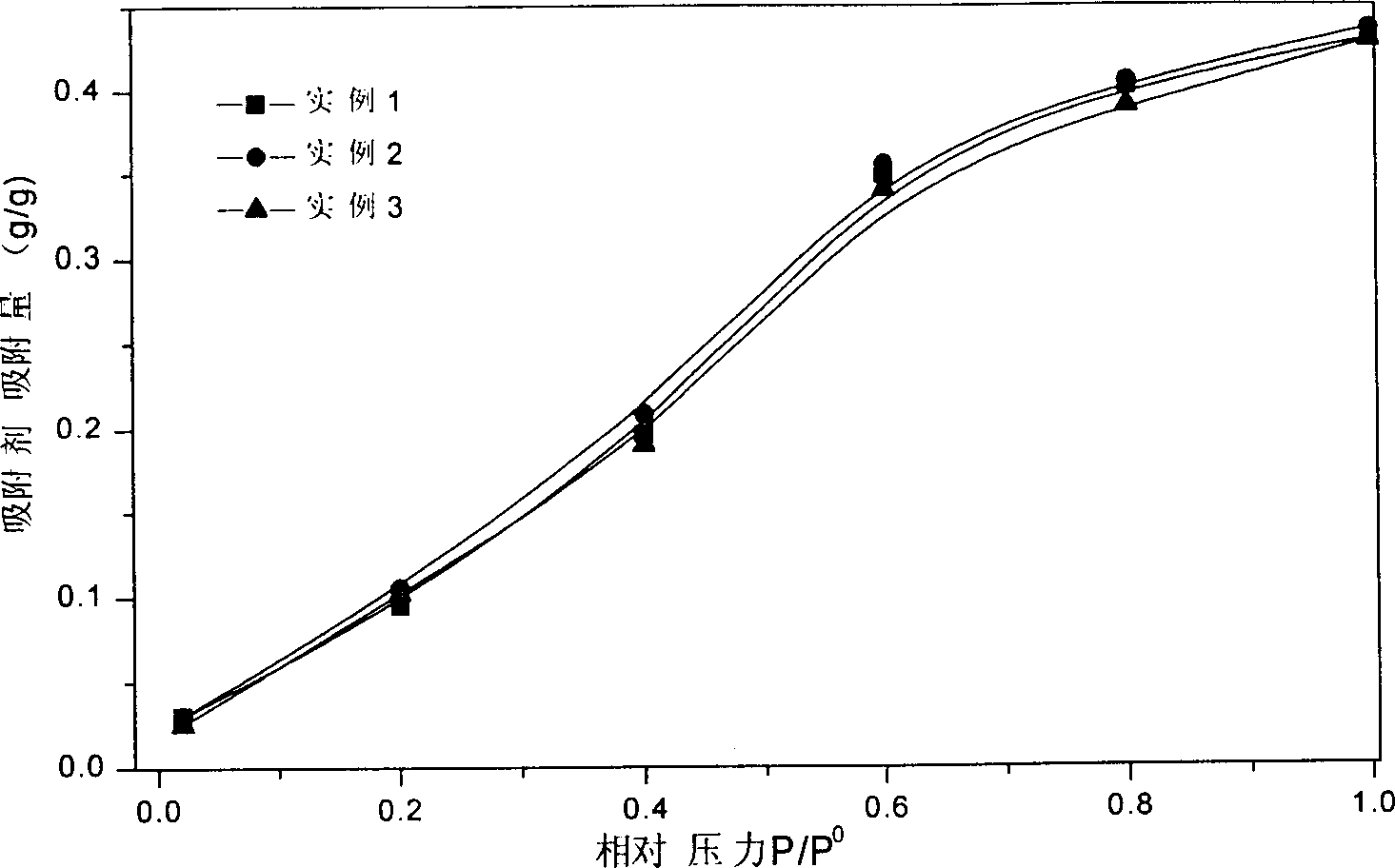

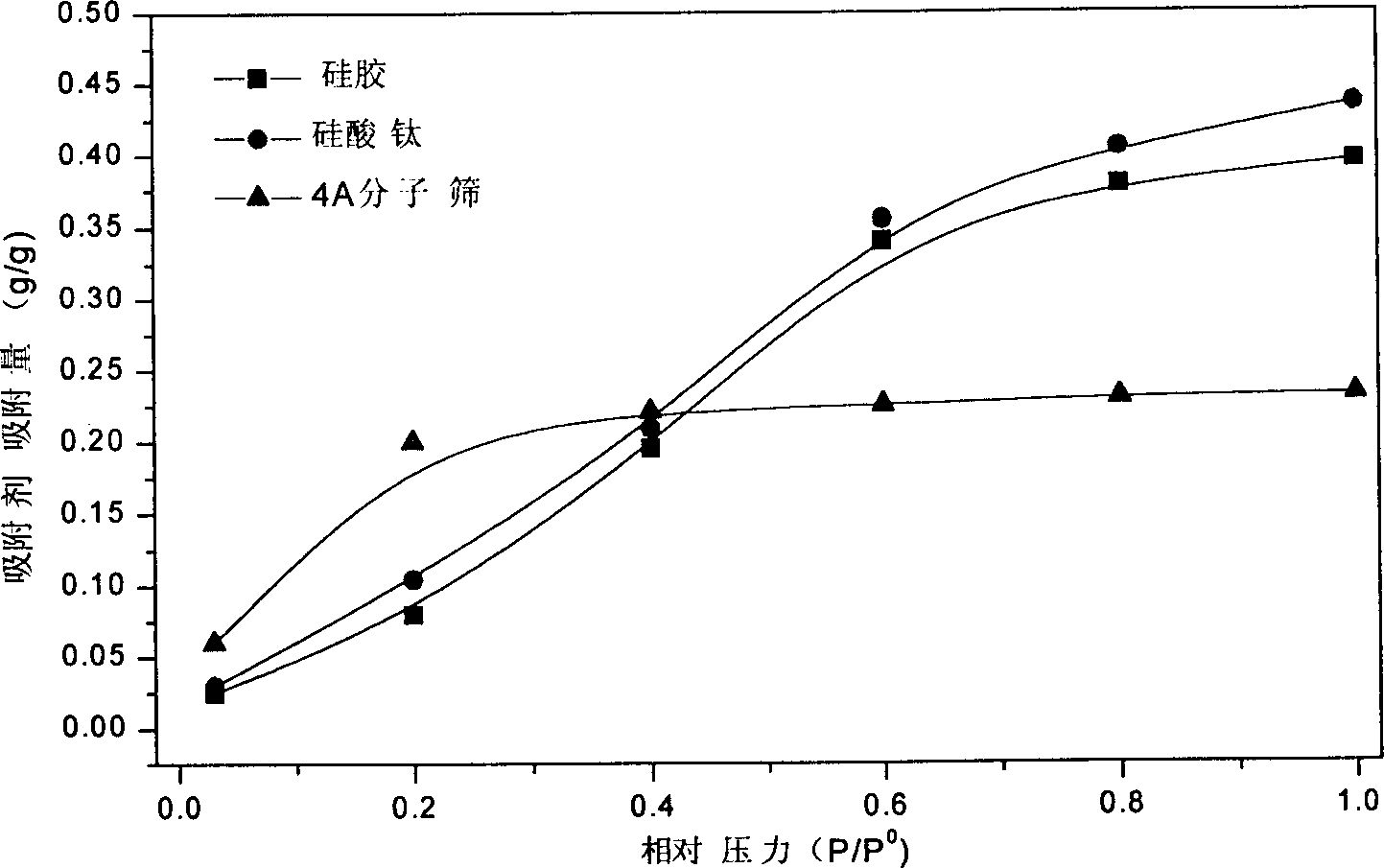

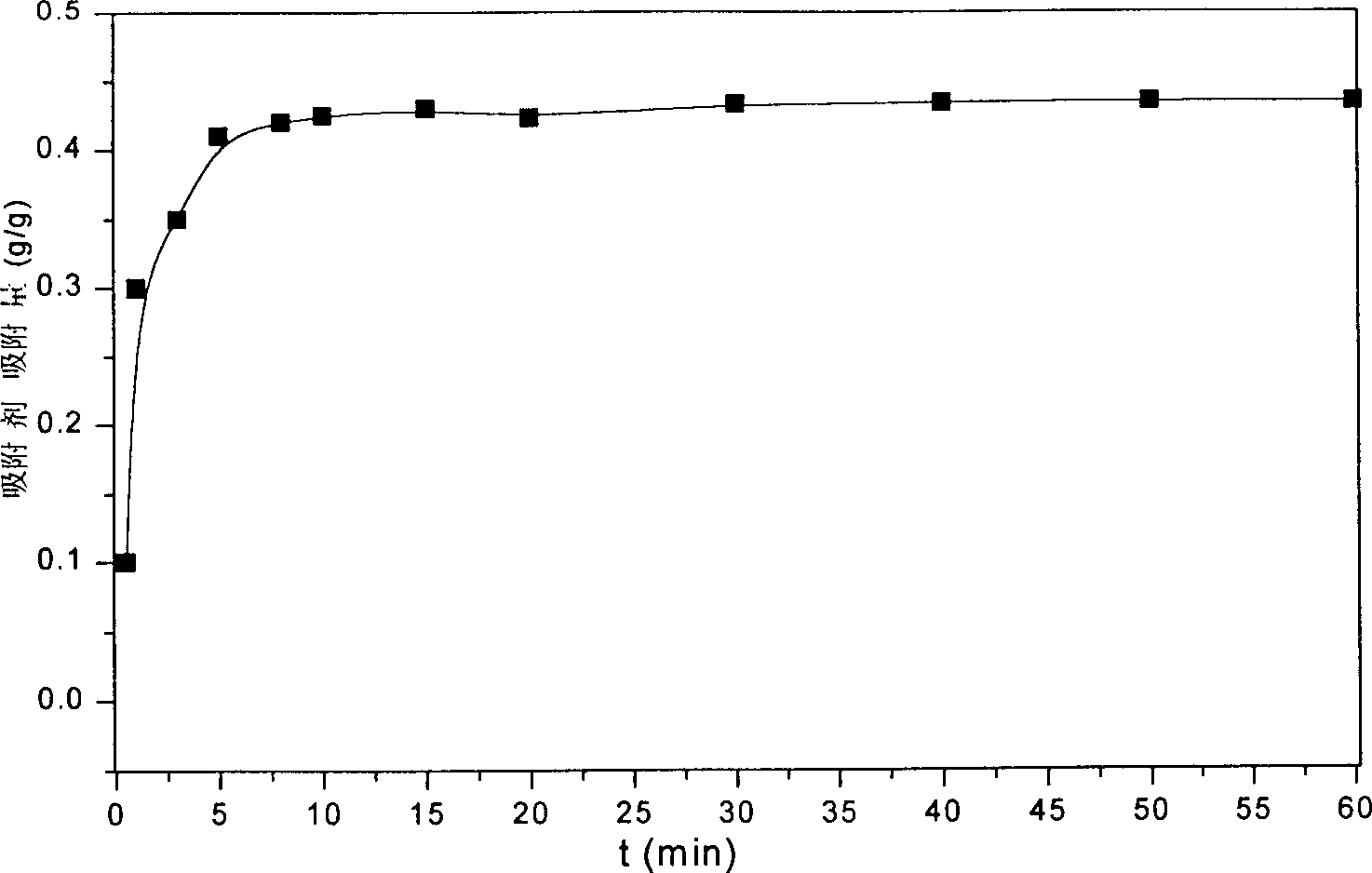

Embodiment 1

[0019] The selected raw materials are: ethyl orthosilicate (TEOS), tetrabutyl titanate (TBtOT), ethanol, polyethylene glycol (PEG-600), water, nitric acid, and the specific steps are: (1) under ice-water bath, In a 500mL flask equipped with a magnetic stirrer, dropping funnel and reflux device, add 250g (0.481mol) of 40% TEOS ethanol solution, get 26mL 0.1mol / L nitric acid and 30.3mL deionized water (water / alcoholate molar ratio 6) Mix evenly in the dropping funnel and slowly drop it into the flask. After reacting for 30 minutes, heat up to 45°C. According to Si / Ti=12, add 34.1g of 40% TBtOT ethanol solution (4.01×10 -2 mol), stir evenly, continue to add dropwise the remaining acid solution to make it fully hydrolyzed, after further reaction for 80 minutes, add 1.25g PEG-600 (2.08×10 -3 mol), continue to react for 50 minutes, and cool to room temperature. Stable sol can be formed by aging at 25°C for 7 days; (2) Using oil-free molding technology, adjust the pH value to make t...

Embodiment 2

[0021] The selected raw materials are: ethyl orthosilicate (TEOS), tetrabutyl titanate (TBtOT), ethanol, polyethylene glycol (PEG-600), water, nitric acid, and the specific steps are: (1) under ice-water bath, In a 500mL flask equipped with a magnetic stirrer, dropping funnel and reflux device, add 250g (0.481mol) of 40% TEOS ethanol solution, get 26mL 0.1mol / L nitric acid and 67.8mL deionized water (water / alcoholate molar ratio 10) Mix evenly in the dropping funnel and slowly drop it into the flask. After reacting for 30 minutes, heat up to 45°C. According to Si / Ti=12, add 34.1g of 40% TBtOT ethanol solution (4.01×10 -2 mol), stir evenly, continue to add dropwise the remaining acid solution to make it fully hydrolyzed, after further reaction for 80 minutes, add 1.25g PEG-600 (2.08×10 -3mol), continue to react for 50 minutes, and cool to room temperature. Stable sol can be formed by aging at 25°C for 7 days; (2) Using oil-free molding technology, adjust the pH value to make t...

Embodiment 3

[0023] The selected raw materials are: ethyl orthosilicate (TEOS), tetrabutyl titanate (TBtOT), ethanol, polyethylene glycol (PEG-600), water, nitric acid, and the specific steps are: (1) under ice-water bath, In a 500mL flask equipped with a magnetic stirrer, dropping funnel and reflux device, add 250g (0.481mol) of 40% TEOS ethanol solution, get 26mL 0.1mol / L nitric acid and 114.7mL deionized water (water / alcoholate molar ratio 15) Mix evenly in the dropping funnel and slowly drop it into the flask. After reacting for 30 minutes, heat up to 45°C. According to Si / Ti=12, add 34.1g of 40% TBtOT ethanol solution (4.01×10 -2 mol), stir evenly, continue to add dropwise the remaining acid solution to make it fully hydrolyzed, after further reaction for 80 minutes, add 1.25g PEG-600 (2.08×10 -3 mol), continue to react for 50 minutes, and cool to room temperature. Stable sol can be formed by aging at 25°C for 7 days; (2) Using oil-free molding technology, adjust the pH value to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com