Double-lever interlocking change-over mechanism and method for automatic watch

A technology of reversing mechanism and automatic watch, applied in the direction of automatic winding, ratchet mechanism of clockwork, clocks, etc., can solve the problems of easy abrasion, functional failure, complex structure, etc., achieve high impact resistance and prolong service life , the effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

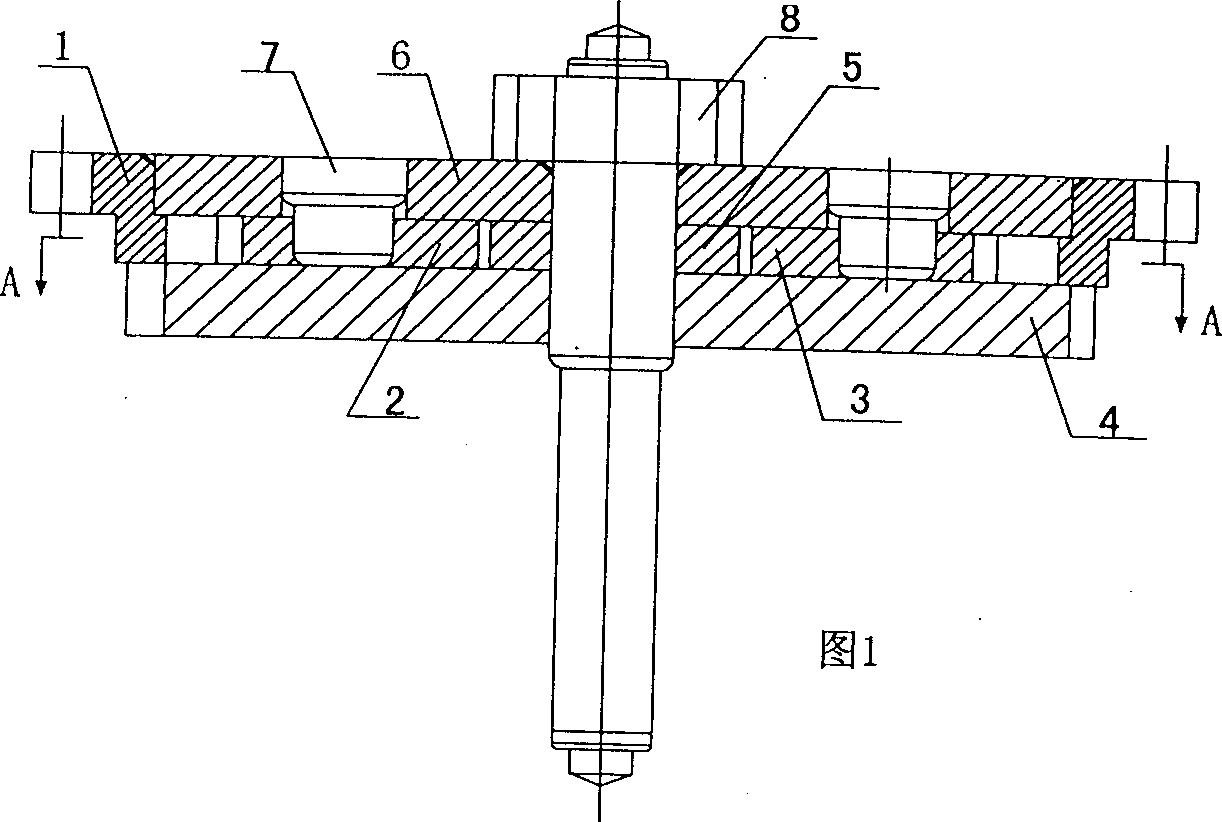

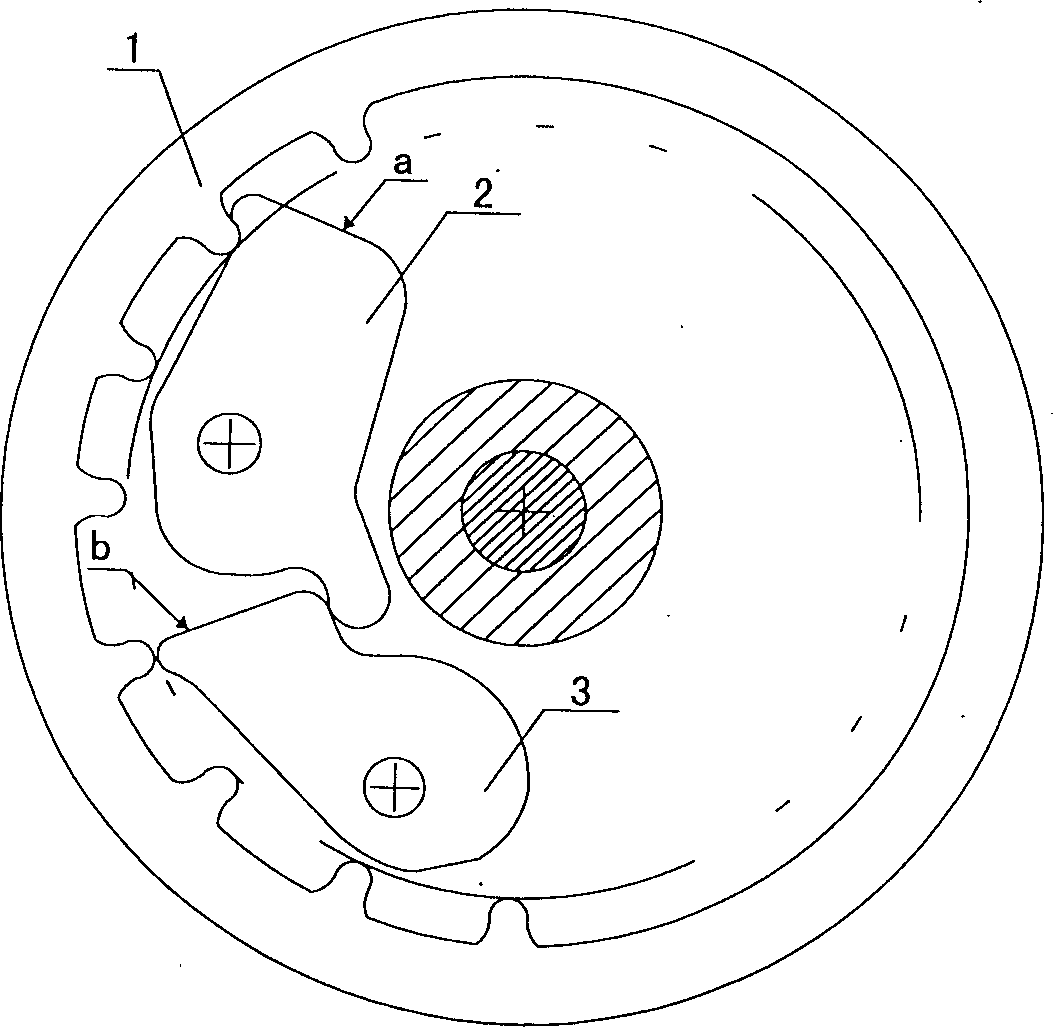

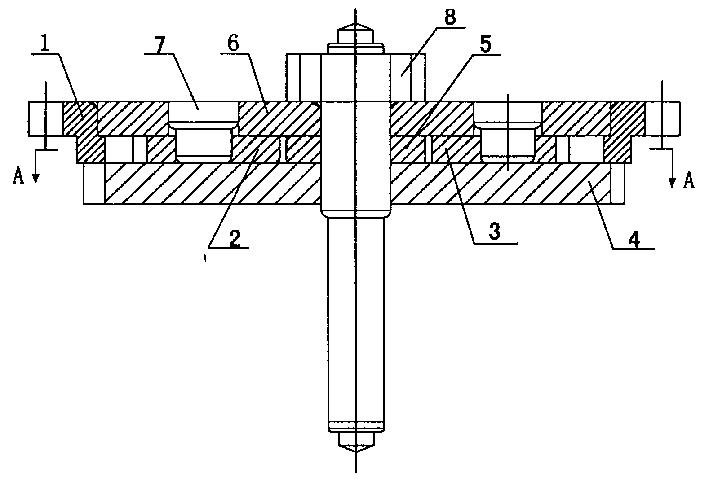

[0008] The inventor thinks that the preferred mode of realizing the present invention can be as follows: (1) according to Fig. 1 and figure 2 As shown, the design and manufacture of the various parts of the double-bar interlocking reversing mechanism: for example: gear 1, swing rod 2 and swing rod 3, ratchet 4, nail 7, gear shaft 8 can be made of high carbon steel or stainless steel, It is machined by the general watch parts processing method; the gear 1 is machined by blanking, rolling the outer teeth, punching the inner teeth and other processes; the swing lever 2 and the swing lever 3 can be stamped; the ratchet 4 is processed It is machined by punching blanks and rolling outer gears; the nail 7 can be machined directly; the gear shaft 8 can be machined by blanking and hobbing; the spacer ring 5 and the wheel sleeve 6 can be made of copper alloy The material is processed by stamping; (2) After designing, processing and manufacturing all parts, according to Figure 1 and fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com