Metal copper nano granules, its preparation method and application

A technology of nano-particles and metal copper, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of restrictions, easy oxidation applications, etc., and achieve high load-carrying capacity and good anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Get the mixed solvent of 200ml distilled water and ethanol (V 水 :V 乙醇 =1:1), injected into a reactor with a constant temperature jacket, kept the temperature at 50° C., and added 0.01 mole of bis(hexadecyl)dithiophosphate and excess hydrazine hydrate. At this time, the solution is clear and transparent, and the pH of the solution is ≈9-10. Under the vigorous magnetic stirring, the high-purity N 2 After 20 minutes, 0.05 moles of fully dissolved copper acetate Cu(AC) 2 ·H 2 O was added once, the solution turned from clarification to brick red and then to brown and transparent, and brown flocculent precipitates appeared slowly, reacted for 2.0 hours, left to stand and aged overnight, filtered hot, and precipitated with hot water, ethanol, acetone in turn Wash several times to remove inorganic impurities and unreacted phosphorothioate, and vacuum-dry to obtain powder.

[0026] The transmission electron microscope (TEM) analysis of the product shows that its particle si...

Embodiment 2

[0028] Get the mixed solvent of 100ml distilled water and ethanol (V 水 :V 乙醇 =1:1), injected into a reactor with a constant temperature jacket, kept the temperature to 50°C, added a certain amount of hydrazine hydrate to make the pH of the solution ≈9-10, and passed high-purity N 2 After 20 minutes, 0.05 moles of fully dissolved copper acetate Cu(AC) 2 ·H 2 O was added at one time, reacted for 3 hours, left to stand and aged overnight, filtered hot, and the precipitate was washed with hot water, ethanol, and acetone several times in order to remove inorganic impurities, and vacuum-dried to obtain nano-copper powder without organic modifier modification.

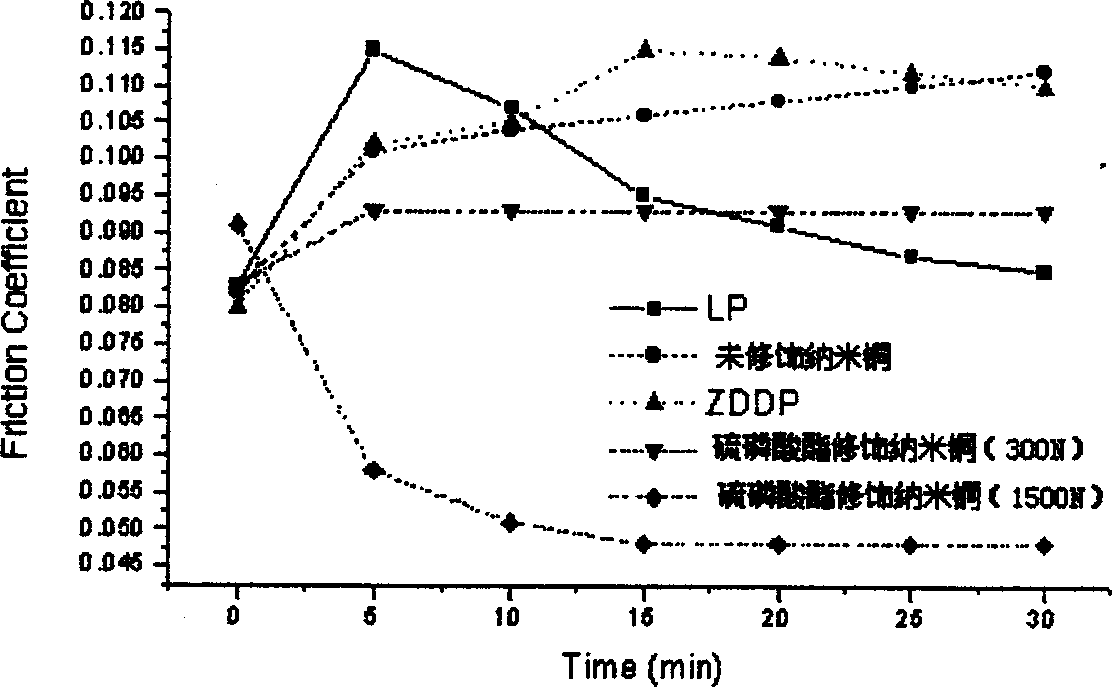

[0029] The transmission electron microscope (TEM) analysis of example 1 and example 2 products shows that the particle diameter of unmodified nano-copper is about 40 nanometers (nm), and the particle diameter of phosphorothioate-modified nano-copper is about 6 nanometers (nm).

Embodiment 3

[0031] Get the mixed solvent of 200ml distilled water and ethanol (V 水 :V 乙醇 =1:1), injected into a reactor with a constant temperature jacket, kept the temperature at 50° C., and added 0.01 mole of bis(dodecyl)dithiophosphate and excess hydrazine hydrate. At this time, the solution is clear and transparent, and the pH of the solution is ≈9-10. Under the vigorous magnetic stirring, the high-purity N 2 After 20 minutes, 0.02 moles of fully dissolved copper acetate Cu(AC) 2 ·H 2 O was added once, and the solution quickly turned from clarification to brick red and then to brown and transparent, and brown flocculent precipitates slowly appeared, reacted for 2.5 hours, left to stand and aged overnight, filtered hot, and the precipitate was washed with hot water and ethanol three times in turn , Acetone several times to remove inorganic impurities and unreacted phosphorothioate, vacuum dried to obtain powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com