Semirigidity activated leakproof paste

A semi-rigid and active technology, applied in other chemical processes, building components, building insulation materials, etc., can solve the problems of poor temperature difference adaptability and anti-aging performance, poor adhesion of dense structures, and inability to adapt to economic construction. Achieve the effects of strong anti-aging ability, good bonding performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

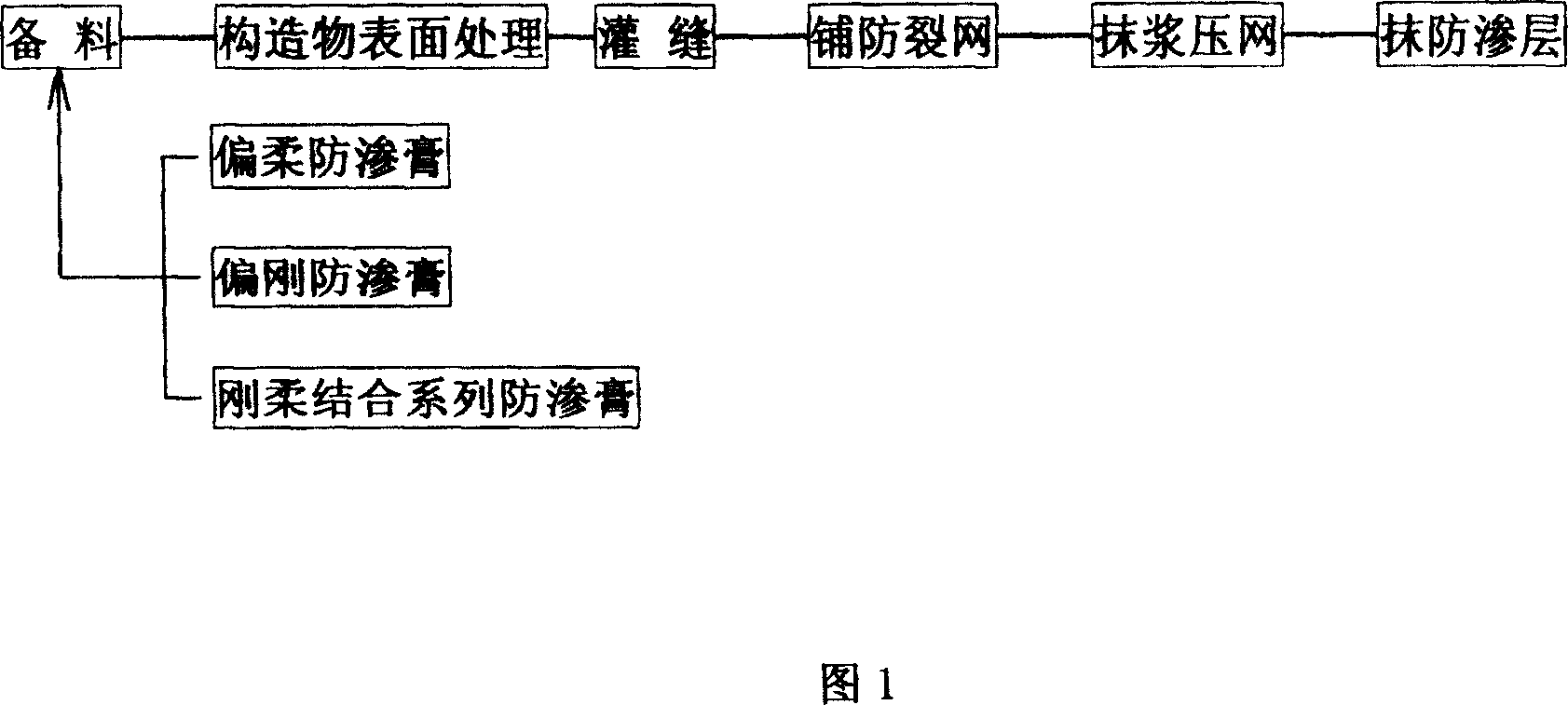

Method used

Image

Examples

Embodiment 1

[0029] Flexible semi-rigid active anti-seepage paste, composed of the following ingredients (weight ratio):

[0030] Cement 50, mineral powder 25, fly ash 15, silica fume 10, sand 100, fiber 0.1, cement retarder 0.4, asphalt 200;

Embodiment 2

[0032] Rigid semi-rigid active anti-seepage paste, composed of the following ingredients (weight ratio):

[0033] Cement 50, mineral powder 25, fly ash 15, silica fume 10, sand 100, fiber 0.1, water reducing early strength agent 0.4, asphalt 80;

Embodiment 3

[0035] Generally semi-rigid active anti-seepage paste is composed of the following ingredients (weight ratio):

[0036] Cement 30, mineral powder 40, fly ash 10, silica fume 5, sand 80, fiber 0.01, cement superplasticizer 0.03, asphalt 50;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com