Muffler with variable acoustic properties

A technology of acoustic characteristics and mufflers, applied in mufflers, machines/engines, thin material processing, etc., can solve problems such as natural cooling is not always sufficient, corrosion, aging of temperature-sensitive parts, etc., to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

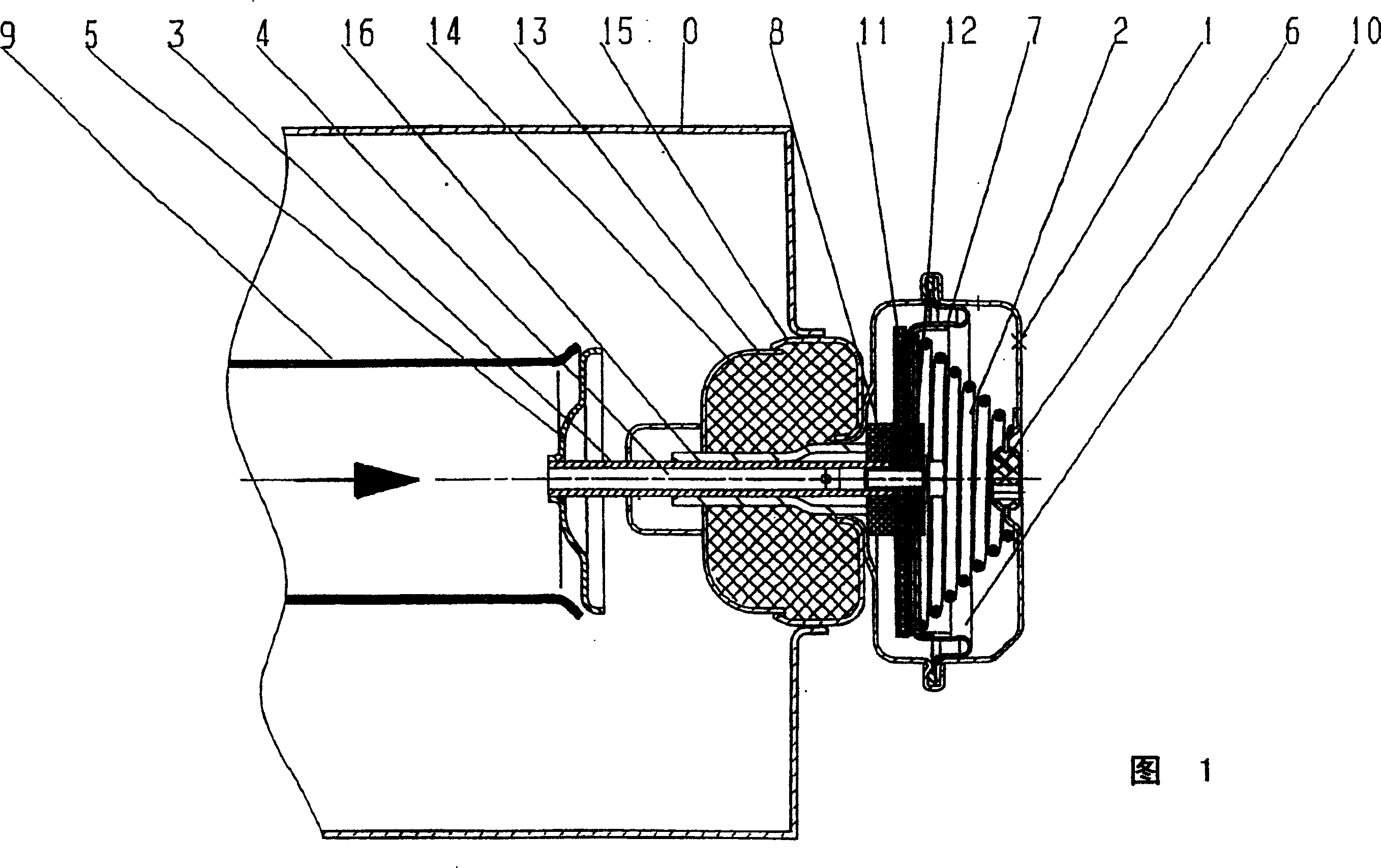

[0023] The drawing shows a thermal pulse gas silencer in a sectional view, in which only a section of the housing wall 0 is shown. An exhaust valve is assembled in the opening of the housing wall 0 through an assembly 15. This exhaust valve has a pressure nozzle 1 with a diaphragm 10, a spring 2, a piston 7 and a piston rod 3, in which a pressure connection pipe 4 is integrated. A closing member 5 in the form of a valve disc is fitted on the free end of the piston rod 3. The closing member 5 opens or closes the cross section of the air duct 9 integrated into the silencer.

[0024] Once the exhaust gas enters the pipe 9, the high pressure generated therein is transmitted to the pressure side of the diaphragm or piston 7 through the pressure connecting pipe 4 integrated into the piston rod 3. The diaphragm is open to the spring 2 and atmospheric external pressure, and the external pressure acts on the low pressure side of the piston 7 through the opening 6 in the pressure nozzle 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com