Non-crimping polyester monofilament and process for producing same

A single fiber and polyester single technology, applied in the field of polyester single fiber, can solve the problems of reducing physical properties and functions, reducing single fiber inhibition, low compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0120] As shown in Table 1, polyester (polyethylene terephthalate) resin is heat-treated in a nitrogen environment (oxygen-free environment) at 280-300°C for 5-15 minutes, and each heated sample is Intrinsic viscosity measurement. Table 1 shows the reduction in intrinsic viscosity under each heat treatment condition.

[0121] Table 1

[0122] Table 1 shows that the higher the heating temperature and the longer the heating time, the greater the decrease in the intrinsic viscosity of the polyester resin. That is to say, the decrease in intrinsic viscosity after heat treatment at 300°C for 10 minutes is 0.071 larger than the decrease in intrinsic viscosity at 280°C for 5 minutes.

[0123] When the polyester resin heat-treated at 300°C for 10 minutes is melted and sprayed at a coiling speed of 1200m / min at an extrusion speed of 4.27g / min, and the unstretched finished product is drawn at a stretch ratio of 3.8 In the case of filaments, the ultimate elo...

reference example 2

[0128] A polyethylene terephthalate resin having an intrinsic viscosity [η] of 0.90 was melted in a melt extruder, and the melting temperature of the resin was controlled at 290°C. The melt was passed through a heating box heated to 300° C. with a heating medium, and then extruded through a metering gear pump at 0.3 ml / rev (milliliter / rev). The measured temperature of the melt extruded through the metering pump was 300°C. During the melting of the above melt and the extrusion of the gear pump, the extrusion rate of the gear pump is shown in Table 2, and the intrinsic viscosity of the extruded molten sample was measured. Its measured values are shown in Table 2,

[0129] No.

[0130] Table 2 shows that: the greater the extrusion speed of the gear pump, the shorter the residence time of the melt in the gear pump, the higher the intrinsic viscosity of the extruded melt, and the lower the intrinsic viscosity of the extruded melt The smaller the amount. The absolute ...

example 1

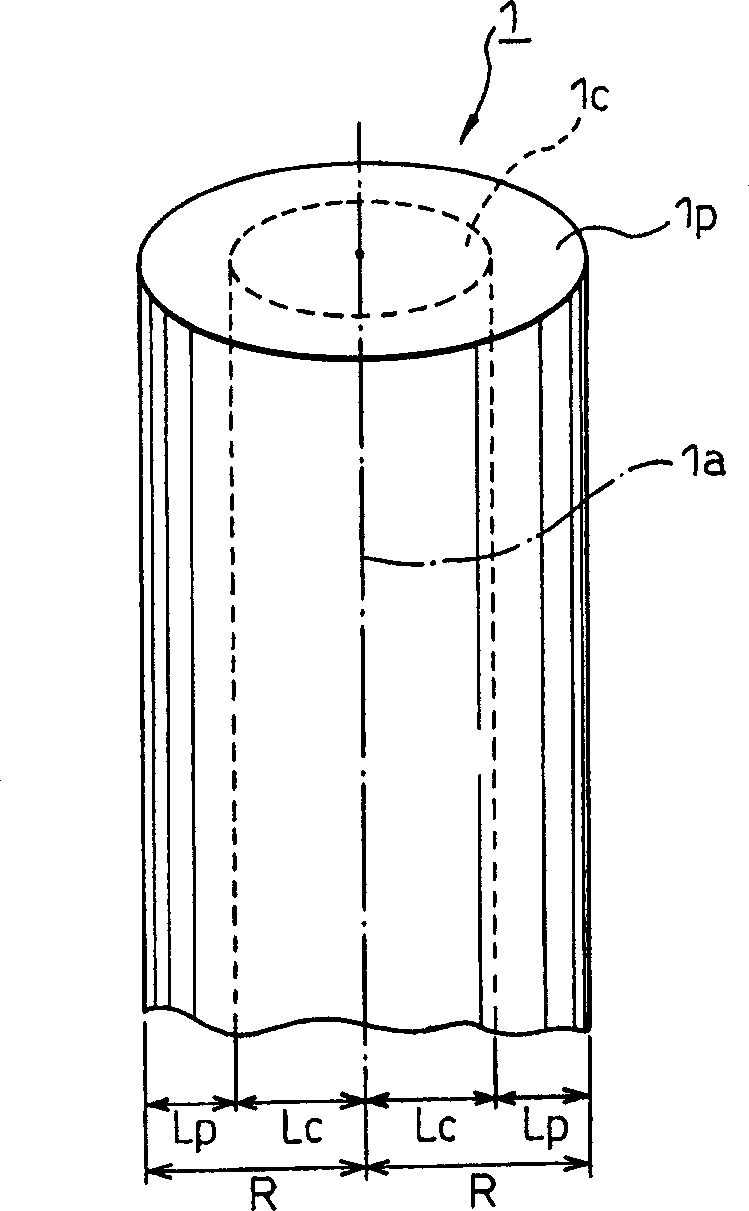

[0135]The polyethylene terephthalate resin with an intrinsic viscosity of 0.8 is melted at 300°C, and enters through the metering gear pump 14 at a speed of 5ml / min. Figure 3(a) and 3(b) The melt spinneret shown. Figure 3(a) and 3(b) The melt spinneret 12 shown has a total internal volume of 12 ml, the central channel 16 of the distribution disc 18 has a diameter of 5 mm, and 24 peripheral channels 17 are arranged concentrically around the central channel 16 . The diameters of the surrounding channels are shown in Table 4. The mixed flow in the melt chamber 19 was extruded through the melt orifice 23 at an extrusion speed of 5 ml / min. The extruded single fiber flow passed through a heating zone with a temperature of 350° C. and a length of 100 mm, and then was cooled and solidified under the operation of pulling out and coiling at a speed of 1000 m / min. The undrawn finished monofilament enters heated drawing rolls heated to 100°C and 140°C respectively, and is stretched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com