Method for preparing zinc oxide hollow four-foot whisker beam

A zinc oxide and hollow technology, which is applied in the field of preparation and generation of non-ferrous metal compounds, can solve the problems of unsatisfactory product quality and purity, low yield, etc., and achieves a rich source of raw materials, low production cost, and less equipment used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

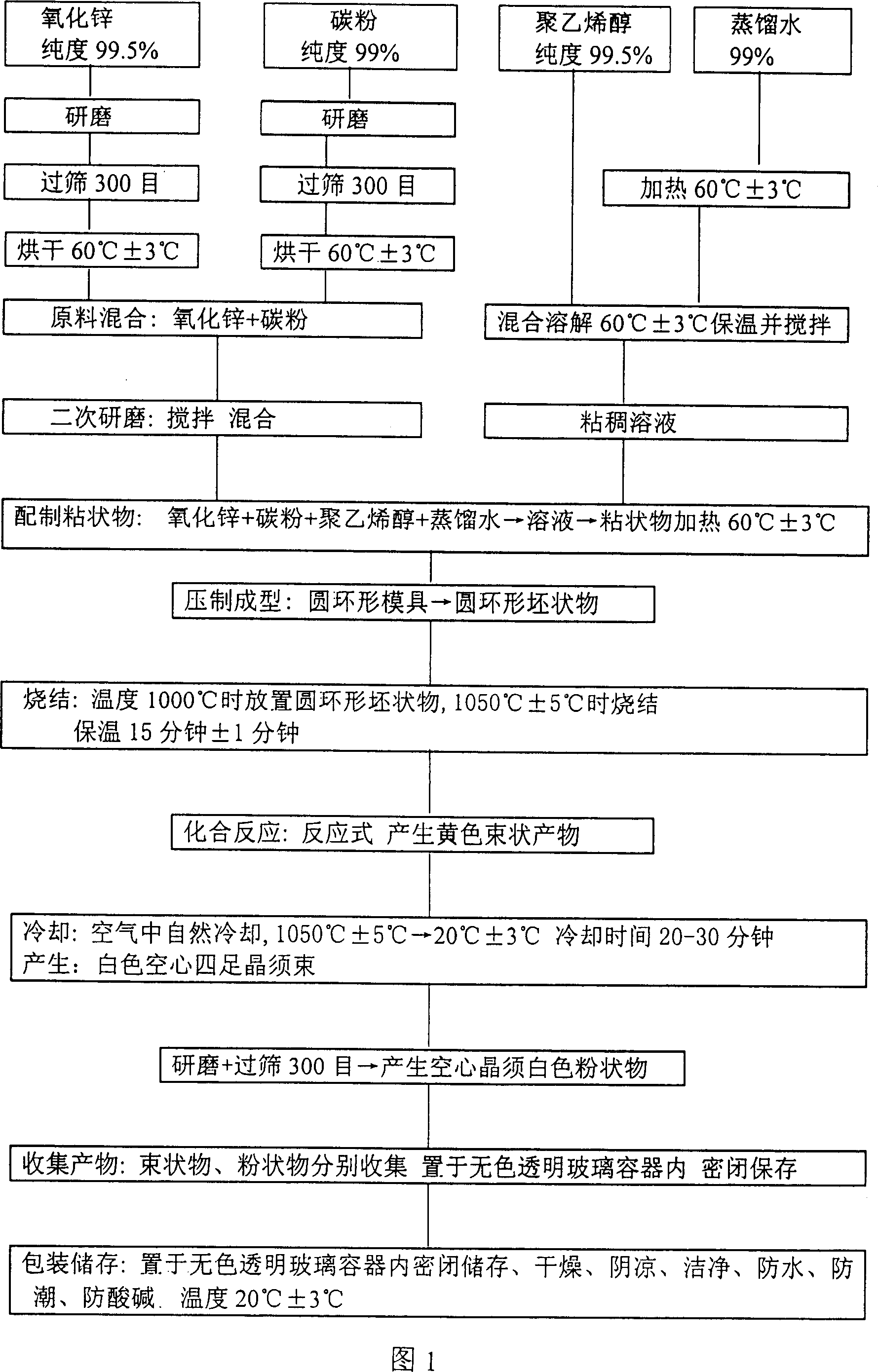

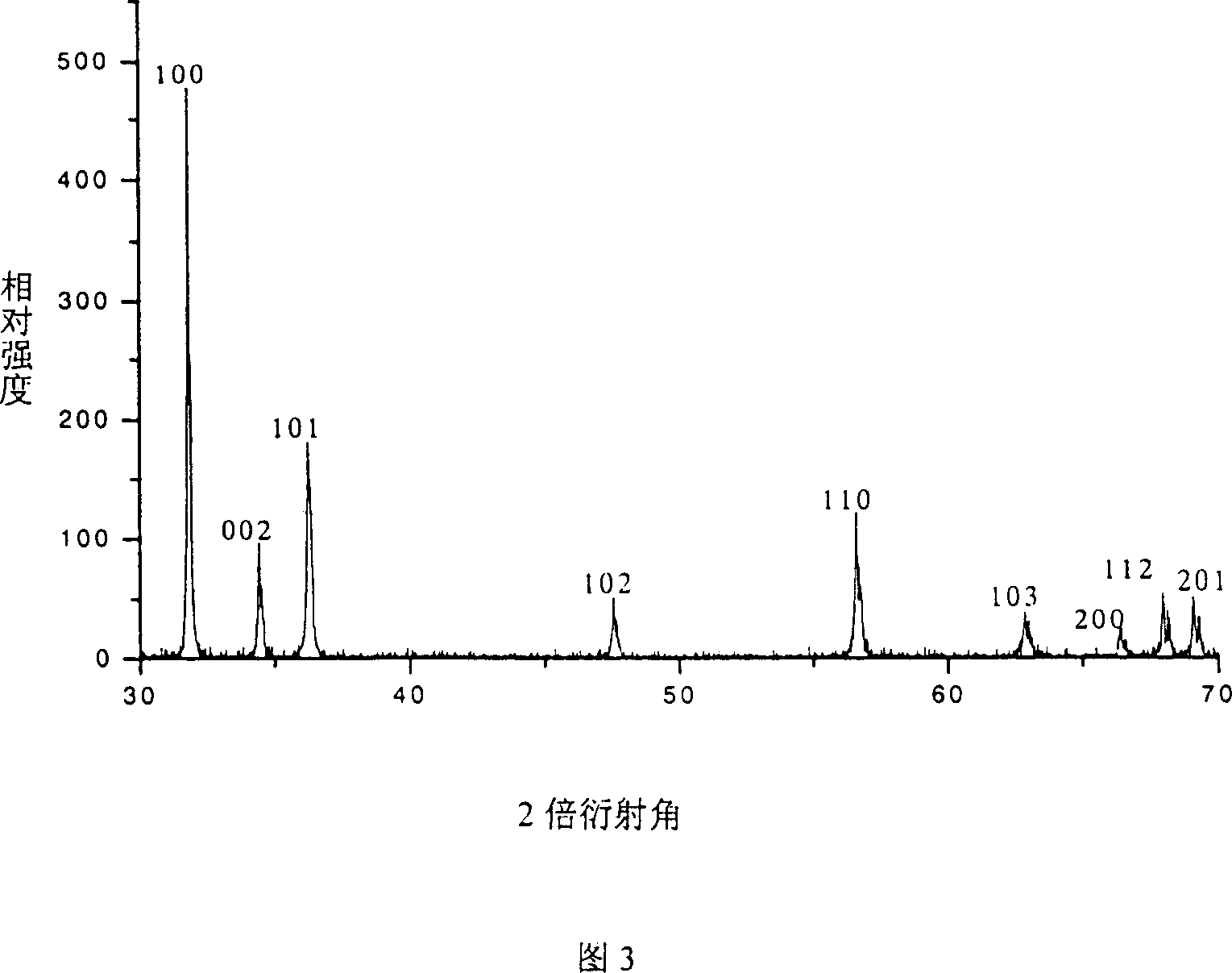

[0085] Preparation of zinc oxide hollow tetrapod whisker bundle:

[0086] Selected zinc oxide 0.5g, charcoal powder 1.5g, polyvinyl alcohol 0.7g, distilled water 0.3ml;

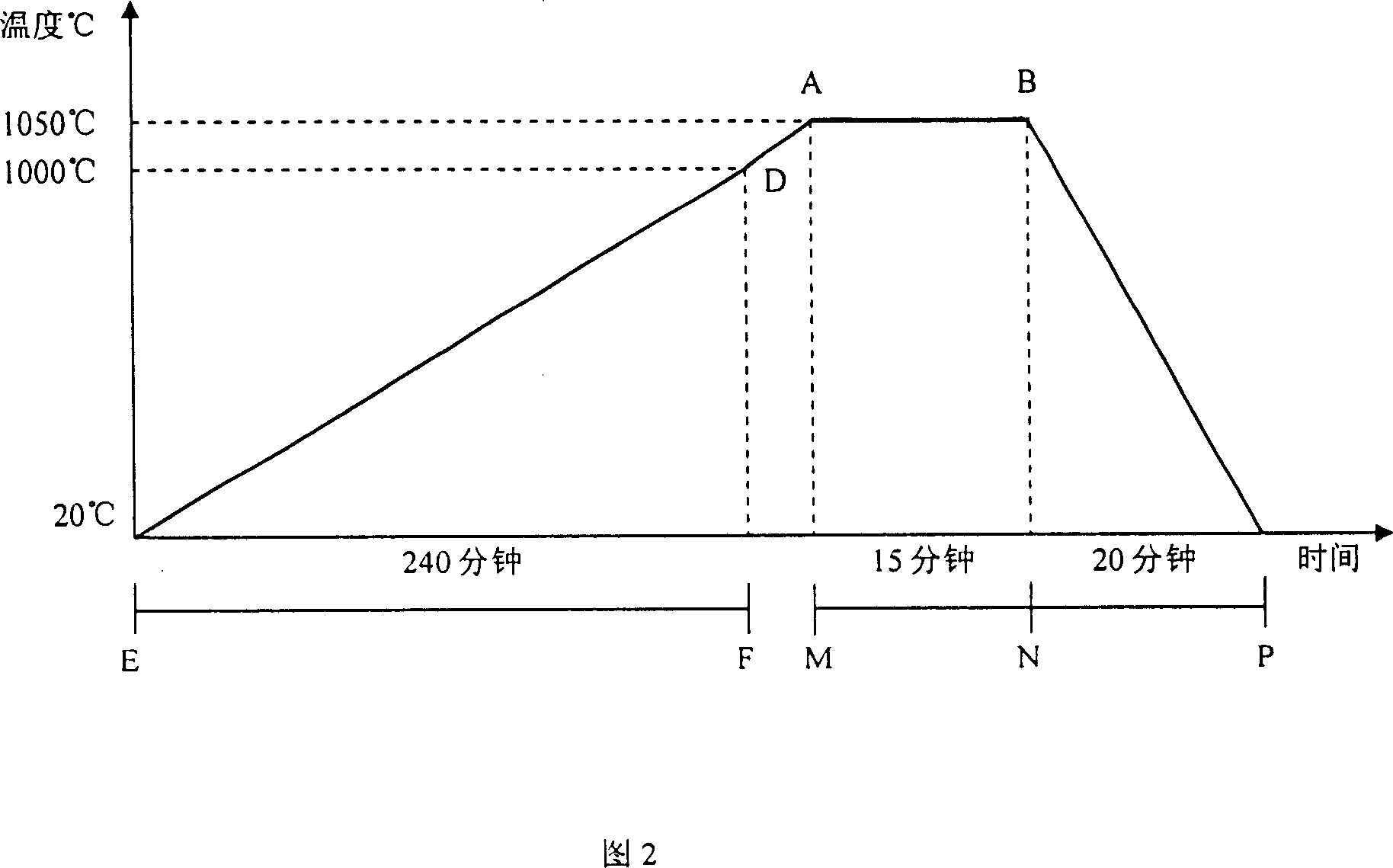

[0087] Put 0.5 grams of zinc oxide and 1.5 grams of carbon powder in an agate mortar, grind them into fine powder with a grinding rod, and then sieve them with a 300-mesh sieve, repeatedly grind and sieve, leave the fine powder, remove Coarse powder; dry the remaining fine powder in a drying oven at 60°C±3°C, mix the dried fine powder according to the combination ratio, and stir evenly with a magnetic stirrer, and then perform secondary grinding ;

[0088] Mix and stir 0.7 g of polyvinyl alcohol and 0.3 ml of distilled water under heating at 60°C±3°C to form a viscous solution, that is, polyvinyl alcohol solution, and then put the mixed and secondary ground zinc oxide and carbon powder into the In the polyvinyl alcohol solution, stir evenly to form a viscous material, then place the viscous material in seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com