Method for synthesizing zeolite by fly ash and application thereof

A technology for synthesizing zeolite and fly ash, which is applied in chemical instruments and methods, other chemical processes, adsorbed water/sewage treatment, etc., can solve the problems of low operating costs and investment costs, and achieve labor saving, low operating costs, and low operating costs. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

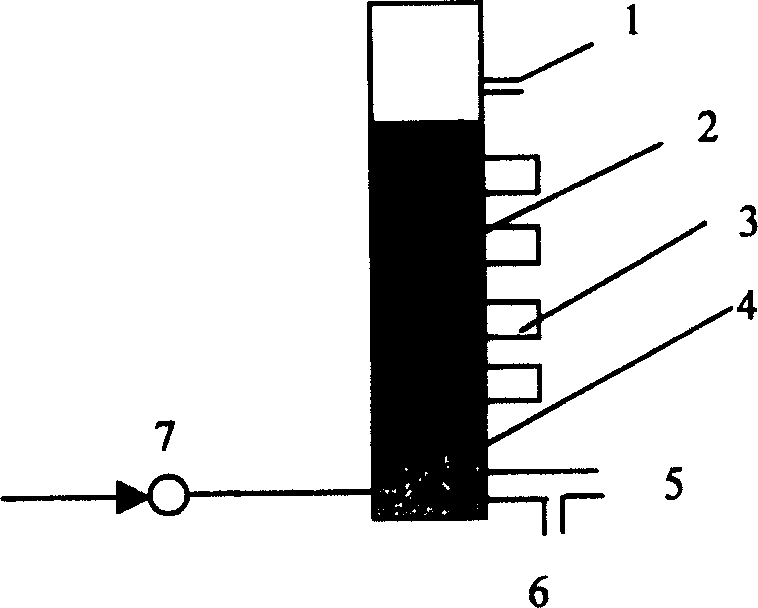

Image

Examples

Embodiment 1

[0027] The solid waste fly ash remaining after coal combustion is used as raw material, and sodium silicate and table salt are added as ingredients, wherein the sodium silicate is 20% of the weight of the fly ash, and the table salt is 40% of the weight of the fly ash. Take 1M (molar concentration) NaOH solution, mix it with the fly ash after adding ingredients at a liquid-solid ratio of 6, react at a temperature of 95°C for 24 hours, and then dry the solid phase after solid-liquid separation to obtain pulverized coal Ash synthetic zeolite. Then the fly ash was synthesized into zeolite for activation, using 0.5M CaCl 2 solution, mixed with fly ash zeolite at a ratio of liquid to solid of 5, and then separated from solid and liquid after saturation treatment, washed away unadsorbed salts, dried, and converted into calcium type that has adsorption activity for nitrogen and phosphorus in sewage Synthetic zeolite from fly ash.

[0028] The transformed and activated fly ash synth...

Embodiment 2

[0030] Sodium silicate and sodium fluoride are added to the fly ash, the sodium silicate is 5% of the weight of the fly ash, and the sodium fluoride is 20% of the weight of the fly ash. Take 2M (molar concentration) NaOH solution, mix it with the fly ash after adding ingredients according to the ratio of liquid to solid ratio of 10, react at a temperature of 120°C for 24 hours, and then dry the solid phase after solid-liquid separation to obtain powdered coal gray zeolite. Then the fly ash synthetic zeolite transformation is activated, using 0.5M (molar concentration) CaCl 2 solution, mixed with fly ash zeolite at a ratio of liquid to solid of 8, separated from solid and liquid after multiple saturation treatments, washed off unadsorbed salts, dried, and converted into nitrogen and phosphorus in sewage. Synthesis of zeolites from calcium-saturated fly ash.

[0031] The transformed and activated fly ash synthetic zeolite is pressed into 8mm particles, dried and packed in a fi...

Embodiment 3

[0033] Metal aluminum foil and sodium chloride are added to the fly ash, wherein the aluminum foil is 5% of the weight of the fly ash, and the sodium chloride is 30% of the weight of the fly ash. The metal alkali solution takes 1M (molar concentration) NaOH solution, mixes it with the fly ash after adding the ingredients according to the ratio of liquid-solid ratio of 5, reacts at a temperature of 95 ° C for 16 hours, and then dries the solid phase after solid-liquid separation. Get fly ash zeolite. Then the fly ash is synthesized into zeolite for activation, using 0.5M (molar concentration) FeCl 3 solution, mixed with fly ash zeolite at a ratio of liquid to solid of 8, and then separated from solid and liquid after saturation treatment, washed away unadsorbed salts, dried, and converted into calcium saturated with adsorption activity for nitrogen and phosphorus in sewage Synthetic zeolite from fly ash.

[0034] The activated fly ash synthetic zeolite is directly added to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com