Magnetic sandwiching layer structure slow-releasing type sorbic acid, and its prepn. method

A slow-release sorbic acid and sorbic acid technology, which is applied in the fields of botanical equipment and methods, animal husbandry, biocides, etc., to achieve the effects of improving bioavailability, improving targeting and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

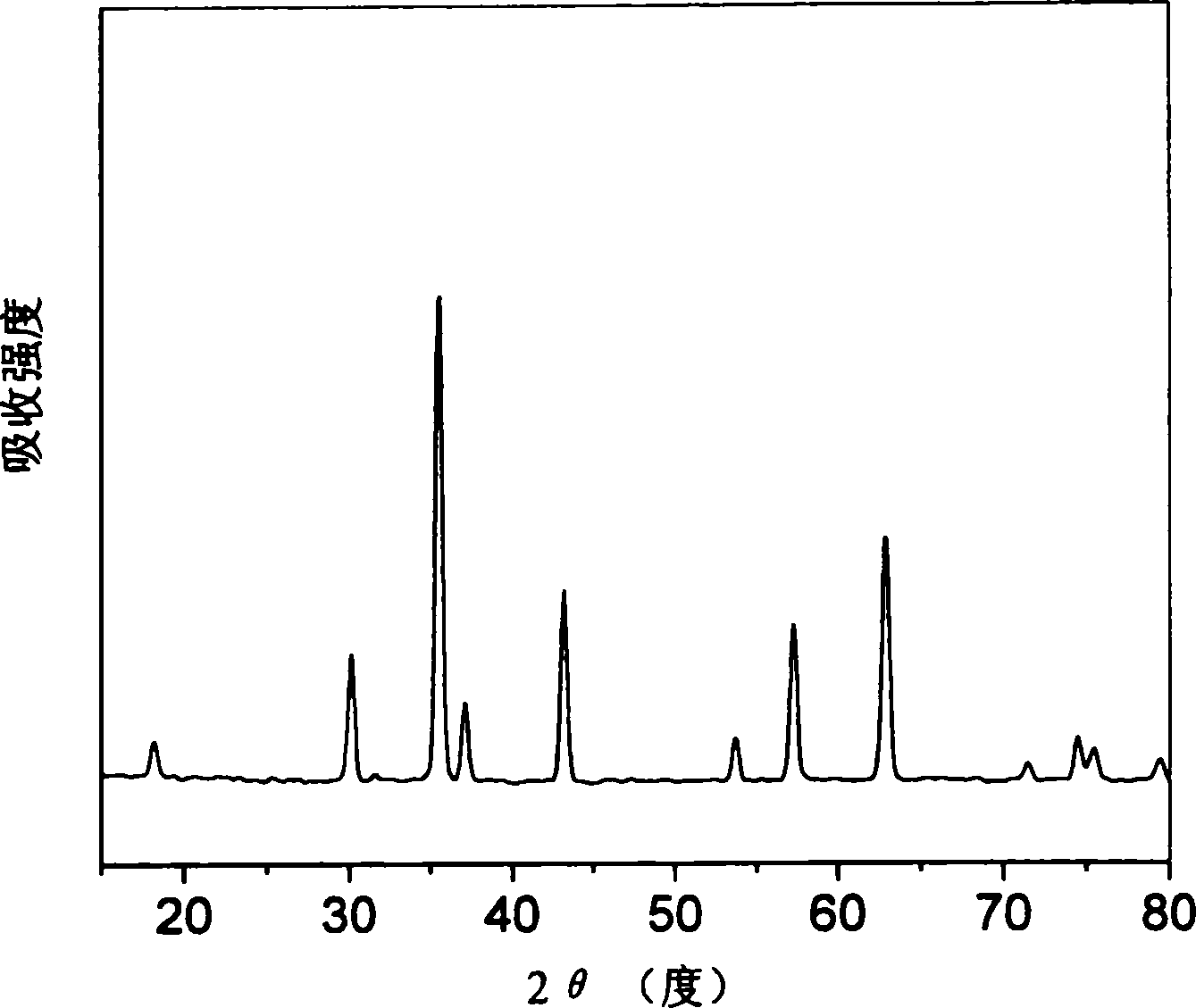

[0036] (1) Magnetic core MgFe 2 o 4 Preparation of Nanopowder

[0037] Weigh 8.47g Mg(NO 3 ) 2 ·6H 2 O and 6.666g Fe(NO 3 ) 3 9H 2 O and 3.29 g FeCl 2 4H 2 O was dissolved in 100ml water to form a mixed salt solution, and 6.02g NaOH and 7.43g NaOH were weighed 2 CO 3 Dissolve in 100ml of water to make a mixed alkaline solution; drop the alkaline solution into the salt solution until the pH value is equal to 6, crystallize in a water bath at 50°C for 4 hours, filter the reaction solution, wash it, and then wash it with absolute ethanol , vacuum-dried, ground into powder, and then calcined at 800°C for 4 hours in an air atmosphere with a heating rate of 10°C / min to obtain the magnetic core MgFe 2 o 4 . Sieve with a standard sieve to obtain a relatively uniform powder. The water used in the process is decarbonized deionized water.

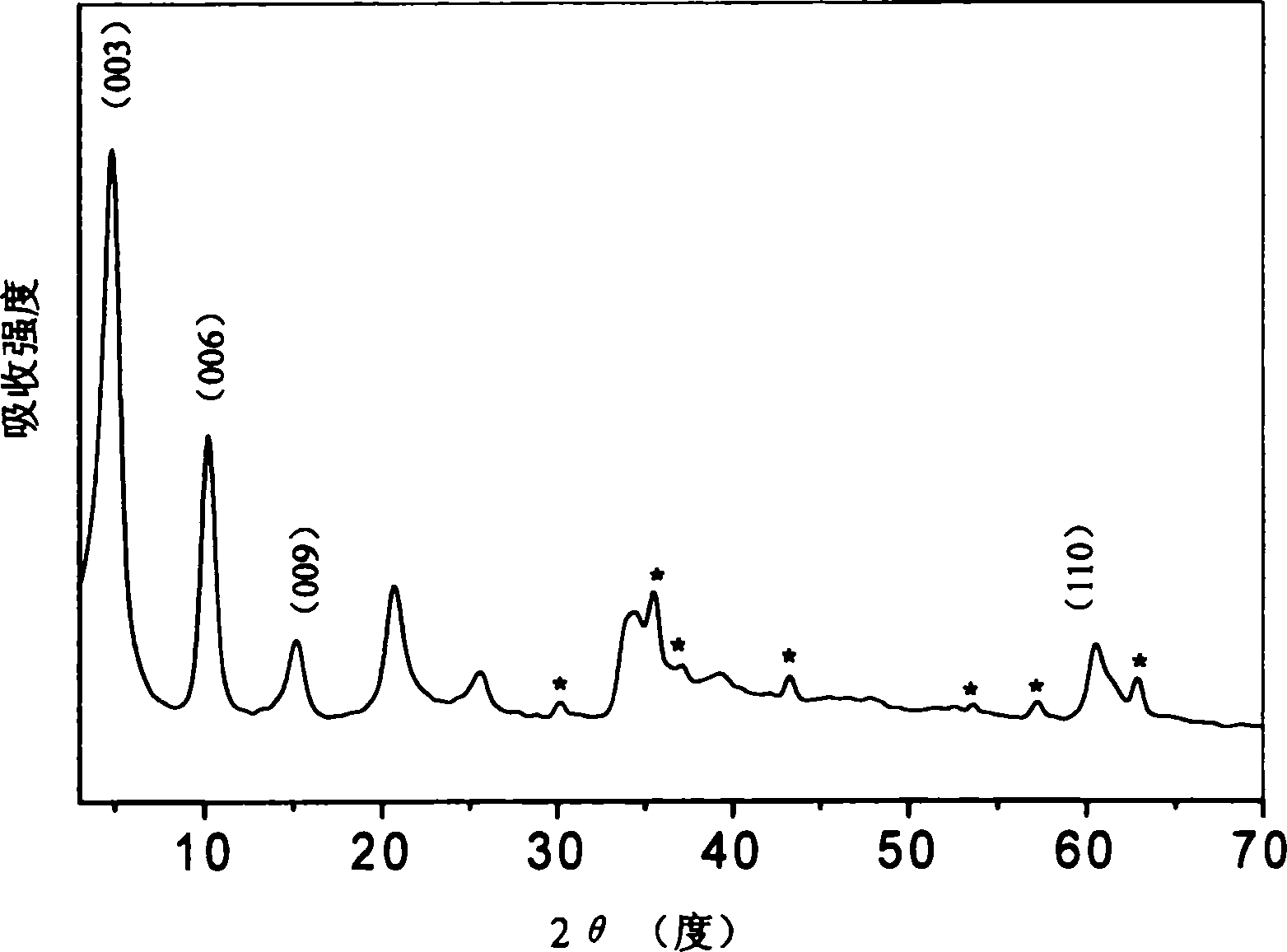

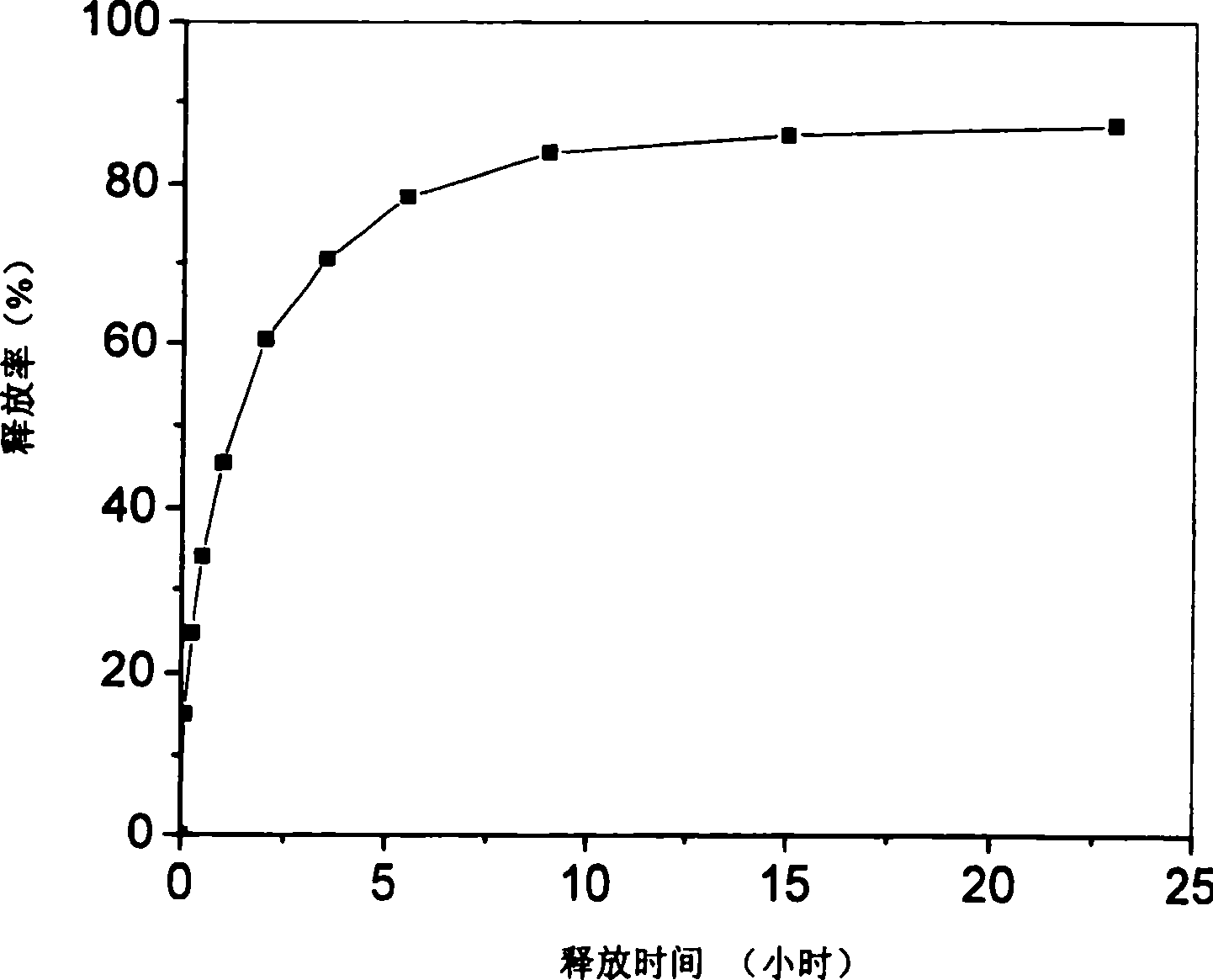

[0038] (2) Preparation of magnetic sorbic acid intercalated zinc-aluminum hydrotalcite

[0039] Weigh Zn(NO 3 ) 2 ·6H 2 O(0.1136mo...

Embodiment 2

[0042] (1) Magnetic core NiFe 2 o 4 Preparation of Nanopowder

[0043] Weigh 10.10g of NiSO at a molar ratio of nickel / ferrous iron / ferric iron of 2:1:1 4 ·6H 2 O, 4.50g FeSO 4 ·7H 2 O and 6.40 g Fe 2 (SO 4 ) 3 ·7H 2 Dissolve O in 150ml water to make a mixed salt solution, weigh 8.00g NaOH and dissolve it in 100ml water to make a mixed alkali solution; under the protection of nitrogen, drop the alkali solution into the salt solution until the pH value is equal to 8, crystallize in a water bath at 15°C After 48 hours, the reaction solution was filtered, washed, washed with absolute ethanol, vacuum-dried, ground into powder, and then calcined at 1000°C for 2 hours in an air atmosphere with a heating rate of 10°C / min to obtain the magnetic core NiFe 2 o 4 . Sieve with a standard sieve to obtain a relatively uniform powder. The water used in the process is decarbonized deionized water.

[0044] (2) Preparation of magnetic sorbic acid intercalated zinc-aluminum hydrota...

Embodiment 3

[0048] (1) Magnetic core NiFe 2 o 4 Preparation of Nanopowder

[0049] Weigh 2.53g of NiSO at a molar ratio of nickel / ferrous iron / ferric iron of 0.5:1:1 4 ·6H 2 O, 4.50g FeSO 4 ·7H 2 O and 6.40 g Fe 2 (SO 4 ) 3 ·7H 2 Dissolve O in 150ml water to make a mixed salt solution, weigh 8.00g NaOH and dissolve it in 100ml water to make a mixed alkali solution; under the protection of nitrogen, drop the alkali solution into the salt solution until the pH value is equal to 7, crystallize in a water bath at 40°C After heating for 16 hours, filter the reaction liquid, wash it, wash it with absolute ethanol, dry it in vacuum, grind it into a powder, and then roast it at 900°C for 2 hours in an air atmosphere with a heating rate of 10°C / min to obtain a magnetic core. NiFe 2 o 4 . Sieve with a standard sieve to obtain a relatively uniform powder. The water used in the process is decarbonized deionized water.

[0050] (2) Preparation of Magnesium Aluminum Hydrotalcite Intercala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com