Method of cracking heavy hydrocarbon to prepare low-carbon olefin and the cracking gasifier system

A technology for pyrolysis gasification and low-carbon olefins, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc. It can solve the problems of excessive waste sand discharge, low heat utilization and production efficiency, and wear of sand furnace process equipment, so as to avoid Effects of pollution, high thermal efficiency, and frequency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

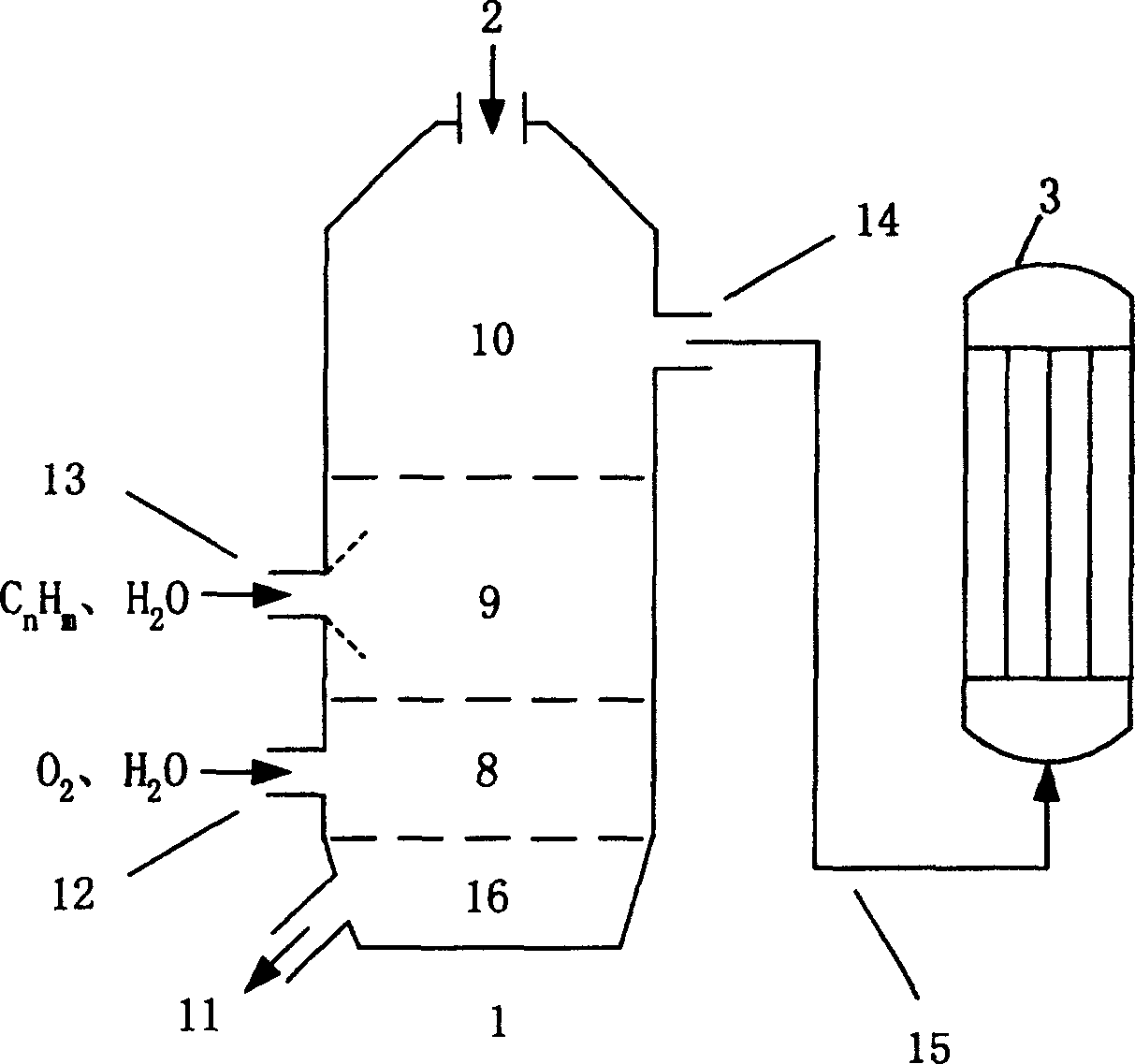

[0046] reference figure 1 In this embodiment, a metallurgical blast furnace is used, especially the retired blast furnace 1 of an iron and steel enterprise can be used as the main body for transformation. At its bottom is a hearth 16. The furnace body of the pyrolysis gasifier is divided into three sections. Up to 1 / 5 of the furnace body is the combustion zone 8, and below the height of the furnace body from 1 / 5 to 3 / 5 is the gasification and cracking zone 9. The part above the gasification and cracking zone is the gasification completion zone 10; in the combustion zone 8 A first gas inlet 12 is opened on the furnace body wall, and a second gas inlet 13 is opened on the furnace body wall of the gasification cracking zone 9, and a gas outlet 14 is opened on the furnace body wall of the gasification completion zone 10, and the gas outlet is 14 is connected to the waste heat boiler 3 through a pipe 15; the first gas inlet 12 is connected to water vapor and oxygen pipes, and the seco...

Embodiment 2

[0050] The method for cracking heavy hydrocarbons to produce low-carbon olefins in this embodiment is carried out in the gasification cracking furnace of embodiment 1, and the specific implementation steps are as follows:

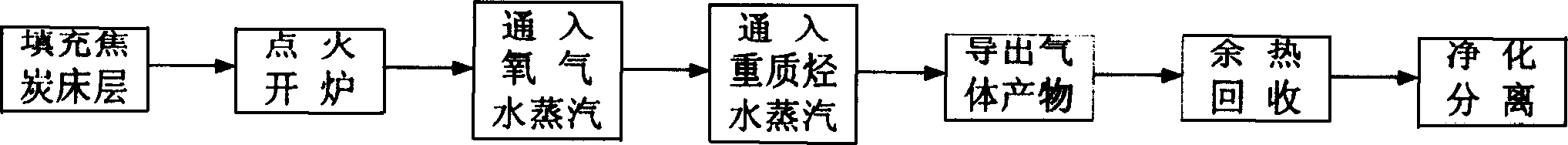

[0051] (1) A bed of coke or semi-coke is filled in the cracking gasifier made in Example 1. The lower part of the packed bed is the combustion zone 8, which occupies 1 / 5 of the entire bed, which provides the necessary for the cracking of heavy hydrocarbons. The middle part of the packed bed is the gasification cracking zone 9, which accounts for 2 / 5 of the entire bed, and the upper part is the gasification completion zone 10, which accounts for 2 / 5 of the entire bed;

[0052] (2) Ignite the furnace;

[0053] (3) Oxygen and water vapor are introduced into the coke bed in the combustion zone 8 at a flow rate of 1.4m 3 / s, the volume ratio of water vapor and oxygen is 5:1, the coke bed is burnt to a hot state; the oxygen is used for the combustion of coke to provi...

Embodiment 3

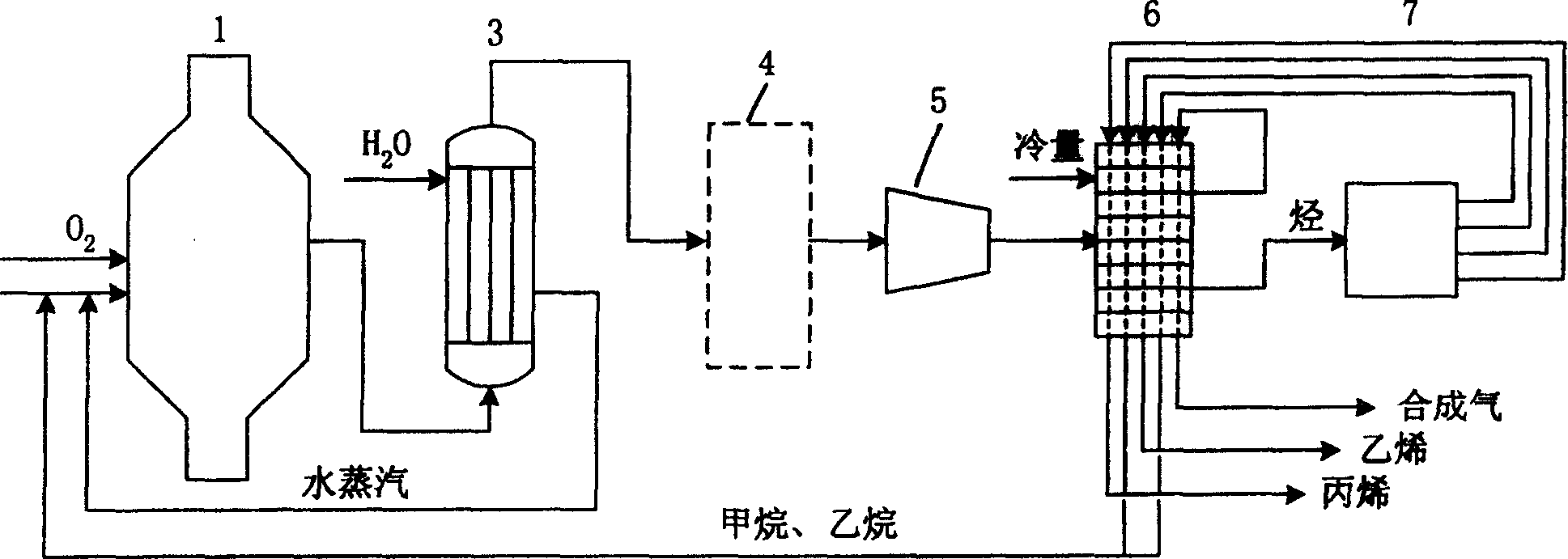

[0063] In the pyrolysis gasifier made in Example 1, press figure 2 The comprehensive utilization of the process flow chart is carried out. The feed of the cracking gasifier includes oxygen, steam and cracking raw materials. Most of the steam is sourced from the heat exchange of the waste heat boiler 3. The cracking raw materials are except heavy hydrocarbons. , Part of the low-carbon alkanes such as methane and ethane returned from the cold box unit 6 and the separation unit 7 are used as raw materials.

[0064] The temperature of the gas outlet 14 of the cracking gasifier is 1073 to 1173K (800 to 900°C), and the cracking and gasification products are passed into the waste heat boiler. After heat recovery, the gas temperature is reduced to 573K (300°C) or less. At the same time, the water used for refrigeration absorbs heat and transforms into water vapor, which is introduced into the cracking gasifier to participate in the reaction.

[0065] The pyrolysis gasification product fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com