Polyphenol red koji antioxidant preservative and its application technology

An anti-oxidant and anti-staling agent technology, applied in application, food preservation, chemical instruments and methods, etc., to achieve the effect of increasing functional efficacy, good shading, and improving flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

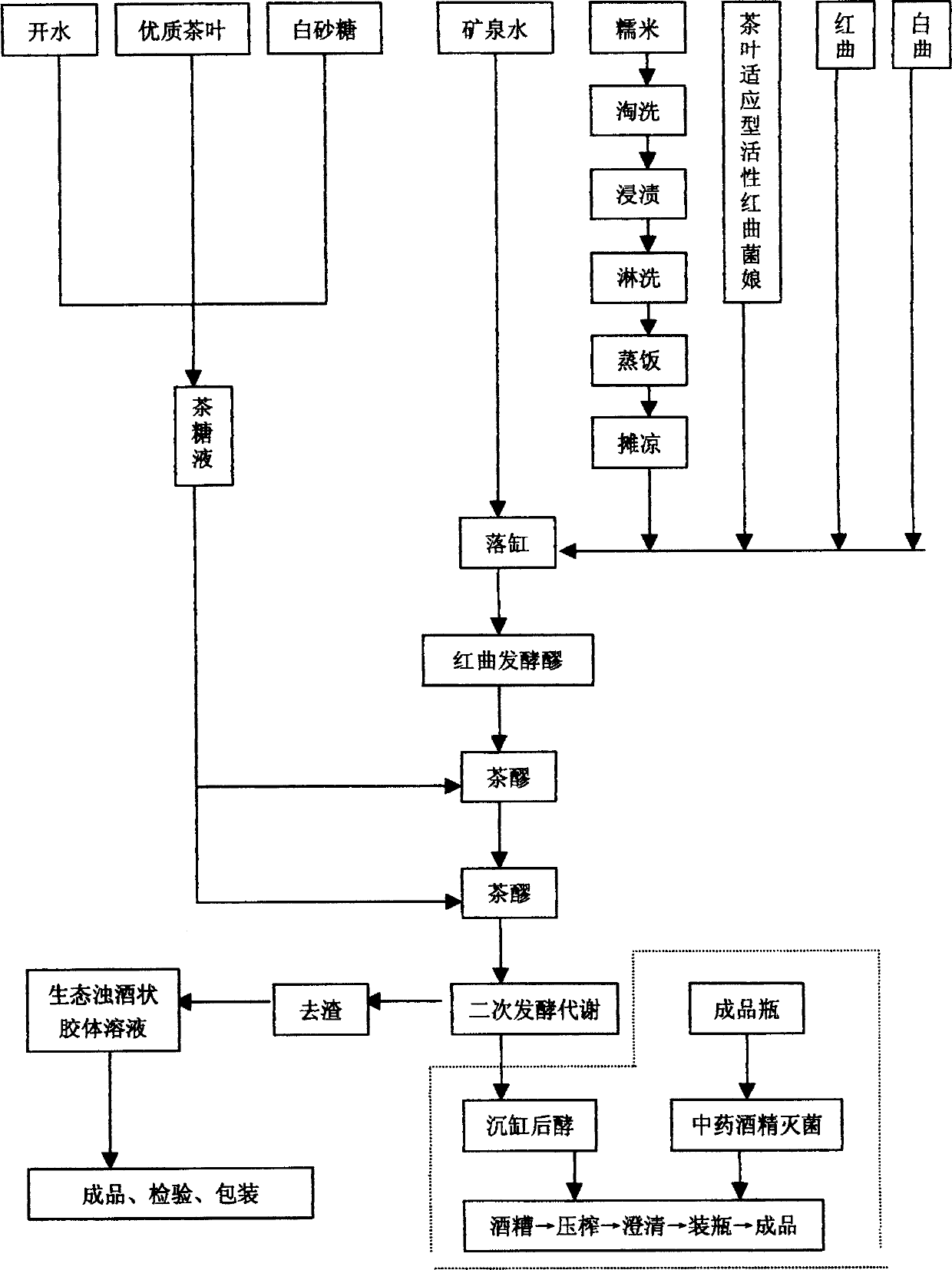

[0055] According to the formula, take 5kg of high-quality green tea, 10kg of red yeast rice, 100kg of high-quality glutinous rice, 1kg of white yeast rice, 160kg of mineral water, 20kg of white sugar, 30kg of boiling water, and 20kg of tea-adapted red yeast rice. According to the process flow chart 1, first, high-quality glutinous rice is washed, soaked, rinsed, steamed into rice, and spread to cool. In addition, red yeast rice is activated in warm water at 20°C for 6 hours, and white yeast is activated in warm water at 38°C containing 5% molasses for half an hour. Mix well with mineral water (28°C) and rice in the tank, control the temperature at 28-30°C, add tea-adapted active Monascus fungus, start saccharification and fermentation, start stirring at 36°C and control the temperature at 30°C for 7 days to make red After a week of koji fermenting, the rice has fully developed, the color is bright red, and the rice cover is thin, and the tea syrup can be prepared. The method is...

Embodiment 2

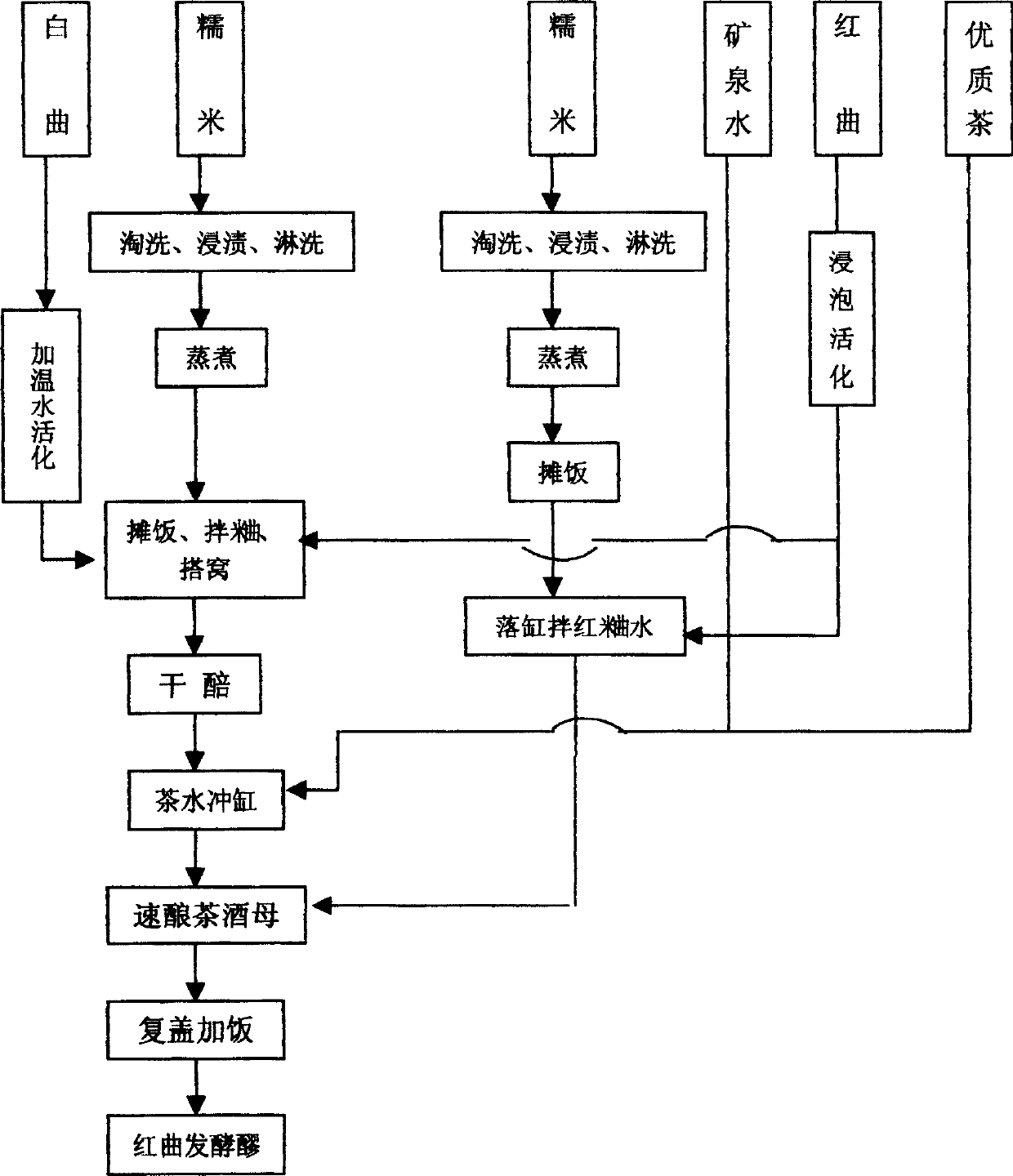

[0057]Take 5.5kg of high-quality green tea, 10kg of red koji, 100kg of high-quality glutinous rice, 1kg of white koji, 160kg of mineral water, 20kg of white sugar, and 30kg of boiled water according to the formula, and use quick-brewed tea distiller's mother instead of tea-adapted active monascus to prepare red koji fermented mash Method: According to the process flow chart 2, first steam 50kg of glutinous rice into rice, spread it to cool, and then activate 2kg of red yeast rice with warm water at 20°C for 6 hours, and activate 1kg of white yeast rice with warm water at 38°C containing 5% molasses for 30 minutes, and then Spread the rice to 28-30°C and mix it with the activated red yeast rice and white yeast rice, drop it into the vat, and build a nest to make dry unstrained spirits. Keep it warm at 28-30°C. After 24 hours, use 0.5kg of tea leaves and 50kg of mineral water to make 28 ℃ tea water into the vat without stirring, and after 6 hours, the quick-brewed tea wine mother...

Embodiment 3

[0062] Green Tea Beer Preparation:

[0063] Get 0.3 tons of polyphenol red yeast rice anti-oxidation preservative prepared according to the above-mentioned embodiment.

[0064] Take materials according to the standard of first-class beer, and prepare 60 tons of qualified saccharification and stereotyped wort according to the existing mature technology, and the wort concentration is 10°-0.3°BX.

[0065] Carry out according to following fermentation technological process:

[0066]

[0067] The above-mentioned key technology is to pump polyphenol red yeast rice anti-oxidation preservative before sealing the can, and adopt the rice wine mixed fermentation technology. The rest of the processes and processes can be carried out according to the standard mature technology of each enterprise. The above-mentioned brewed beer contains green tea polyphenols, and its sensory and physical and chemical indicators of green tea beer are as follows:

[0068] Appearance: transparency, clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com