Method for preparing pale malt containing high-activity limit dextrinase

A technology of limiting dextrinase and light-colored malt, which is applied in the field of preparation of malt for beer production, can solve the problems of low amylase activity, high non-fermentable sugar content, low beer fermentation degree, etc. The effect of low activity rate and strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The first implementation example of the present invention is an industrial scale malting process of pale malt in a ventilated germination box and a three-layer kiln.

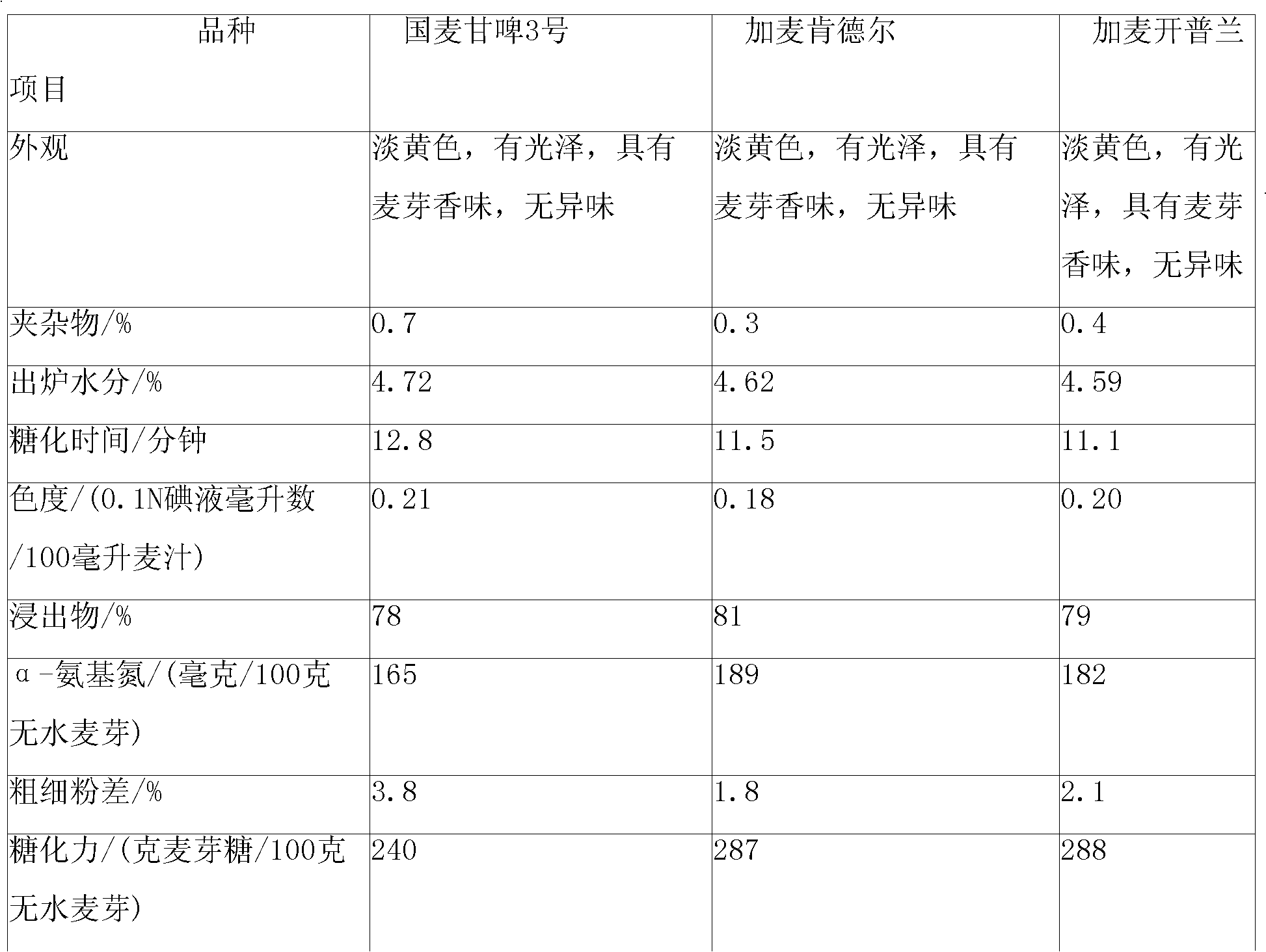

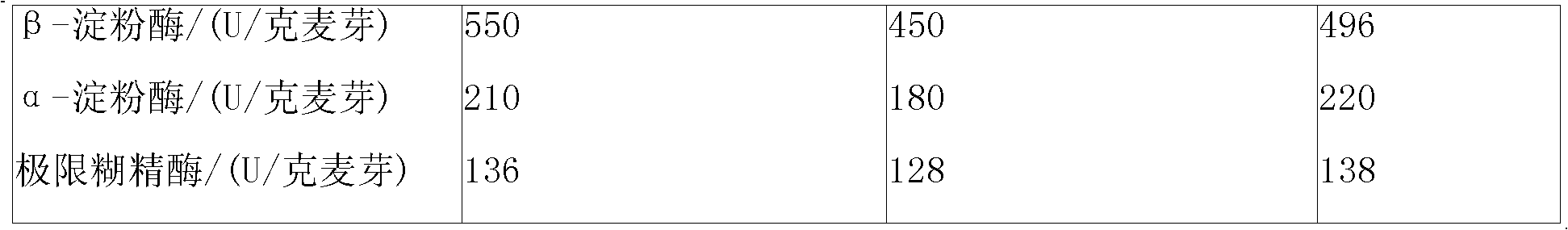

[0055] The test materials of this example are Barley Ganbei No. 3, Gamai Kendall (Kendel), Gamai Kaplan (Copelemd). Barley development, kernel quality and enzyme activity are shown in Table 5.

[0056] Table 5. Barley development, kernel quality and enzyme activities

[0057] Variety

barley development

Kernel quality

Enzyme activity※

Guomai Gan Beer No. 3

Barley skin is thin, the grain is full,

uniform grain

Thousand grain weight: 35

Protein content: 13%

β-amylase > α-amylase

Powder enzyme > limit dextrinase

gamkendall

Barley skin is thin, the grain is full,

uniform grain

Thousand grain weight: 33

Protein content: 11.5%

β-amylase > α-amylase

Powder enzyme > limit dextrinase

Gameplay Kaplan

Barl...

Embodiment 2

[0077] The second implementation example of the present invention is a small-scale small-scale production of light-colored malt in the laboratory using barrel-type immersion malt, artificial climate box (temperature-adjusting and humidity-regulating box) germination, blast drying box drying, and simulating the malting process of factory production. Malting process.

[0078] Simulate the factory malting process under laboratory conditions, and can process six 500g samples at a time. The test material for this example was Copelemd. Barley development, kernel quality and enzyme activity are shown in Table 8.

[0079] Table 8. Barley development, kernel quality and enzyme activities

[0080] Variety

barley development

Kernel quality

Enzyme activity※

Gameplay Kaplan

Barley with thin skin and full grain

, wheat grains are more uniform

Thousand grain weight: 34

Protein content: 12%

β-amylase > α-amylase

>Limited dextrinase ...

Embodiment 3

[0093] The third implementation example of the present invention is a small-scale malting process of light-colored malt in the laboratory using barrel-type immersion, germination in an artificial climate box, and drying in a blast drying oven to simulate the malting process of factory production. To investigate the effects of metal ion concentration, germination promoter concentration and the combined use of germination promoter and metal ions on the enzyme activity of light-colored malt products.

[0094] Simulate the factory malting process under laboratory conditions, and can process six 500g samples at a time. The test material for this example was Kendel. Barley development, kernel quality and enzyme activity are shown in Table 10.

[0095] Table 10. Barley development, kernel quality and enzyme activity

[0096] Variety

[0097] ※In barley, β-amylase shows high activity, while α-amylase and limit dextrinase activity is very low

[0098] The malting conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com