Organic silicate comprising ether, preparing process and application thereof

A technology of organosilicate and acrylic acid, applied in the fields of organic chemistry, organic silicon compounds, chemical instruments and methods, etc., can solve the problems of poor corrosion inhibition effect of organosilicate and can not meet industrial production, and avoid eutrophication. Pollution, good corrosion inhibition effect, not easy to silicate scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

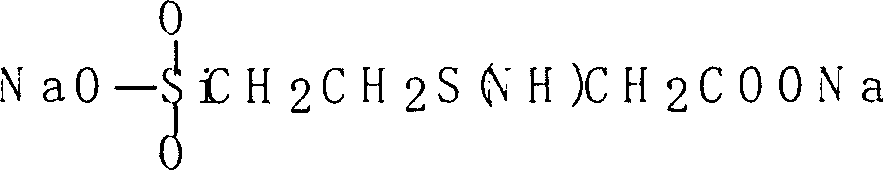

Image

Examples

Embodiment 1

[0026] This embodiment is the preparation of N, N'-two (γ-propyl sodium silicate)-dipolyoxyethylene ether {[(NaO) 3 SiCH 2 CH 2 CH 2 NH] 2 (CH 2 CH 2 OCH 2 CH 2 )}.

[0027] Add 95.7 g (0.42 mol) of γ-aminopropyltriethoxysilane with a molecular weight of 221.0 and a purity of 97% into a 250 mL 4-necked round-bottomed flask equipped with mechanical stirring, start stirring, and protect with nitrogen at the same time. Slowly heat the flask for 15 minutes to make the reaction materials warm up to 105°C, and weigh α, ω-dichlorodipolyoxyethylene ether (Cl-CH 2 CH 2 OCH 2 CH 2 -Cl) 29.8g (0.2mol) is placed in the dropping funnel, when the reaction flask material temperature is 105 ℃, begin to slowly use 2 hours to evenly drop in the reaction flask, the reaction temperature of the dropping process is maintained at 105~ At 115°C, α,ω-dichlorotripolyoxyethylene ether was added dropwise, and then reacted at 110-120°C for 2 hours.

[0028] After the reaction is complete, red...

Embodiment 2

[0033] The present embodiment is the preparation of N, N'-two (gamma-propyl sodium silicate)-pentapolyoxyethylene ether {[(NaO) 3 SiCH 2 CH 2 CH 2 NH] 2 CH 2 CH 2 (OCH 2 CH 2 ) 4}.

[0034]Weigh respectively 95.7g (0.42mol) of γ-aminopropyltriethoxysilane with a purity of 97%, and 57.3g of α, ω-dichloropentapolyoxyethylene ether with a purity of 275.0% according to the examples 1, to obtain 100.7g product (yield 82%).

Embodiment 3

[0036] The present embodiment is the preparation of N, N'-bis(γ-propyl sodium silicate)-octoxyethylene ether {[(NaO) 3 SiCH 2 CH 2 CH 2 NH] 2 CH 2 CH 2 (OCH 2 CH 2 ) 7}.

[0037] Take by weighing 95.7g (0.42mol) of γ-aminopropyltriethoxysilane with a purity of 97% and 95% α, ω-dichlorooctoxyethylene ether 85.7g with a purity of 97%, and the operation steps are according to Example 1 , to obtain 111.9 g of product (yield 75%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com