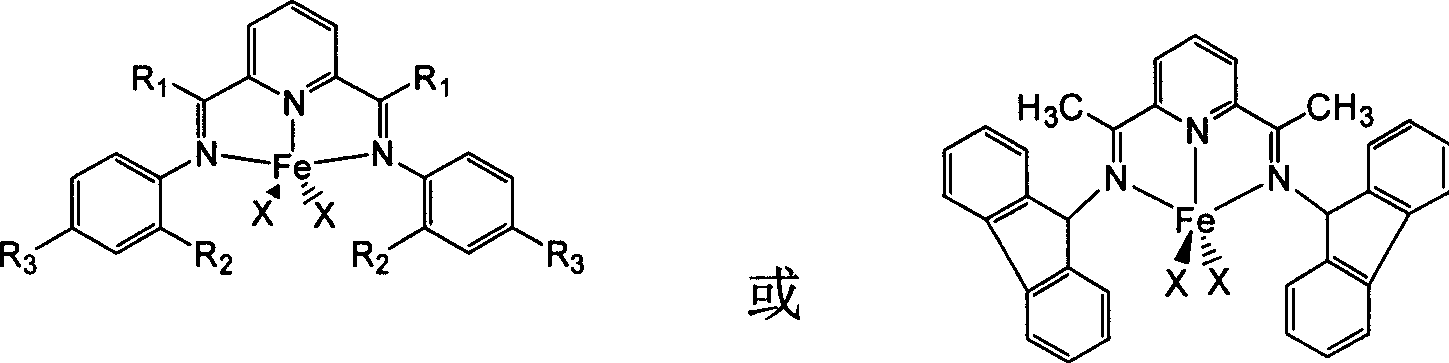

Montmorillonite carrier-formed double-function catalysis system, its preparation method and application

A technology of bifunctional catalysis and catalytic system is applied in the application of the above-mentioned catalytic system in the preparation of linear low-density polyethylene, the preparation of the above-mentioned catalytic system, and the preparation of a montmorillonite carrier-supported copolymerization catalyst in the catalytic system, which can solve the problem of forming Copolymers, ethylene oligomerization catalysts are unstable, etc., and achieve the effects of low melting point, inhibition of sticking kettle phenomenon, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0029] 2. Catalytic system

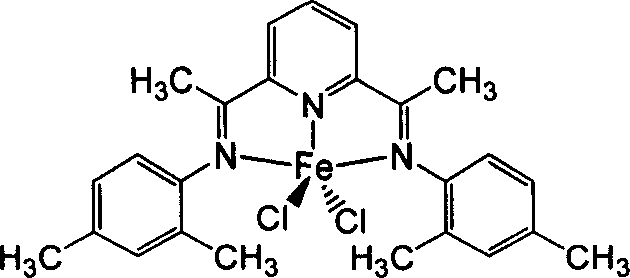

[0030] (a) Oligomerization catalyst (homogeneous)

[0031]

[0032] (b) Preparation of montmorillonite carrier: Dry montmorillonite in vacuum for 8 hours at 60°C, add 1.8mol / L methylalumoxane solution (the weight ratio of methylalumoxane solution to montmorillonite is as follows: 6:1) was stirred at 60° C. for 8 hours, and the unreacted methylaluminoxane was washed with toluene three times, filtered, and dried to obtain a montmorillonite carrier.

[0033] The preparation of montmorillonite-supported ethylene copolymerization catalyst: take 4 grams of above-mentioned montmorillonite, add 30 milliliters of toluene and 0.1gEt(Ind) 2 ZrCl 2 The solution was reacted at 50°C for 12 hours; unsupported Et(Ind) was washed away with toluene 2ZrCl 2 ; Remove the toluene solvent in vacuum, and vacuum-dry at ...

Embodiment 2

[0037] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0038] 2. Catalytic system

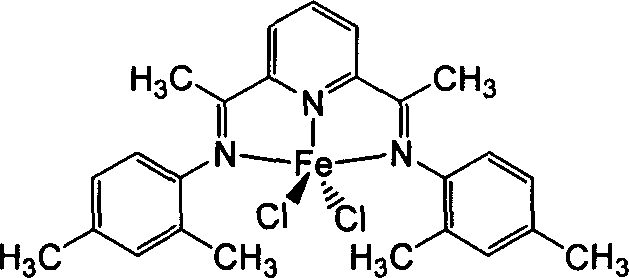

[0039] (a) Oligomerization catalyst (homogeneous)

[0040]

[0041] (b) Preparation of montmorillonite carrier: Dry montmorillonite in vacuum for 8 hours at 60° C., add 1.8 mol / L methylalumoxane solution (the weight ratio of methylalumoxane solution to montmorillonite is as follows: 6:1) was stirred at 60° C. for 8 hours, and the unreacted methylaluminoxane was washed with toluene three times, filtered, and dried to obtain a montmorillonite carrier.

[0042] The preparation of montmorillonite-supported ethylene copolymerization catalyst: take 2 grams of above-mentioned montmorillonite, add 10 milliliters of toluene and 0.5g Me 2 Si(Ind) 2 ZrCl 2 The solution was reacted at 50 °C for 14 hours; unloaded Me was washed away with toluene 2 Si(Ind) 2 ZrCl 2 ; Remove the toluene solvent in vacuum, and...

Embodiment 3

[0046] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0047] 2. Catalytic system

[0048] (a) Oligomerization catalyst (homogeneous)

[0049]

[0050] (b) Preparation of montmorillonite carrier: Dry montmorillonite in vacuum for 8 hours at 60° C., add 1.8 mol / L methylalumoxane solution (the weight ratio of methylalumoxane solution to montmorillonite is as follows: 6:1) was stirred at 60° C. for 8 hours, and the unreacted methylaluminoxane was washed with toluene three times, filtered, and dried to obtain a montmorillonite carrier.

[0051] The preparation of montmorillonite-supported ethylene copolymerization catalyst: take 8 grams of above-mentioned montmorillonite, add 40 milliliters of toluene and 0.3g Et(Ind) 2 ZrMe 2 The solution was reacted at 70°C for 9 hours; unsupported Et(Ind) was washed away with toluene 2 ZrMe 2 ; Remove the toluene solvent in vacuum, and vacuum-dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com