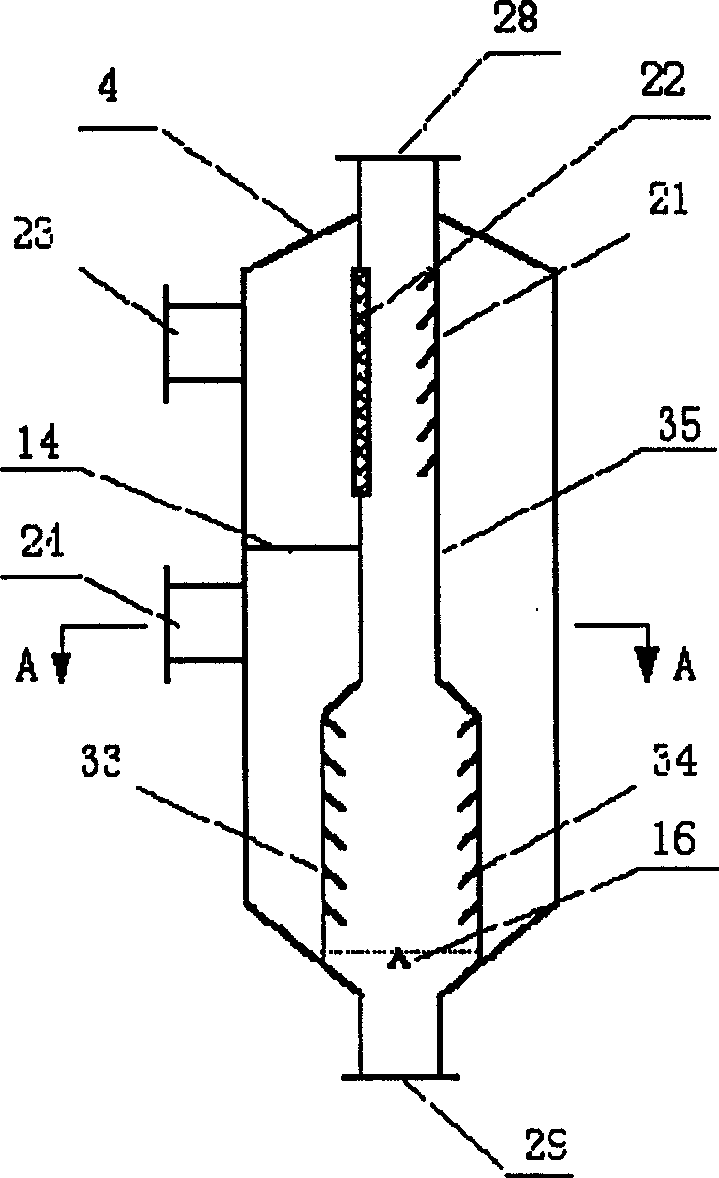

Integrated method and device of high temperature coal gas desulfur and dust removing

A technology for desulfurization, dust removal and coal gas, which is applied in the field of high temperature gas purification, can solve the problems of difficulty in full utilization, corrosion of filter plates, and high filtration gas velocity, so as to reduce equipment investment and operating costs, reduce floor space, and overcome problems of low utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The desulfurizer is a granular iron oxide high-temperature desulfurizer with a particle size of 0.5-3mm. The operating conditions are: the operating temperature is 500 to 550°C, and the operating pressure is 1 MPa (gauge pressure). The composition of oxygen / steam blast gas is (volume percentage): H 2 Content 28%, CO content 25%, N 2 Content 6%, CH 4 Content 1%, CO 2 Content 16%, H 2 O content 24%. The dust concentration in the crude gas is 5.2g / Nm 3 , H 2 S concentration 6000ppmv. First, the iron oxide high temperature gas desulfurizer particles are loaded into the feed hopper 1 and the composite particle bed 4, N 2 Pressurize to 1.0MPa, then introduce high-temperature crude gas from the air inlet 24, control the gas velocity through the bed at about 0.15m / s, start the discharger 6, and control the moving speed of the desulfurizer to be about 36cm / h. The gas enters the lower moving bed through the gas inlet chamber 15, and cross-flow contacts with the desulfuri...

Embodiment 2

[0025] Air / steam blasting produces high temperature gas, the gas composition is (volume percentage): H 2 Content 15%, CO content 13%, N 2 Content 46%, CH 4 Content 1%, CO 2 Content 10%, H 2 O content 15%. The dust concentration in the crude gas is 6.4g / Nm 3 , H 2S concentration 3000ppmv. The moving speed of the desulfurizer is controlled to be about 25 cm / h, and the gas velocity through the bed is controlled to be about 0.1 m / s, and the rest are the same as in Example 1. The dust concentration in the purified gas can be stabilized at 20mg / Nm 3 Below, H 2 S concentration can be stabilized at 30 ~ 100ppmv. All dust with a particle size of 5 μm or more is removed.

Embodiment 3

[0027] The moving speed of the desulfurizer is controlled to be about 18 cm / h, and the rest are the same as in Example 2. The dust concentration in the purified gas can be stabilized at 10mg / Nm 3 Below, H 2 S concentration can be stabilized at 70 ~ 150ppmv. All dust with a particle size of 5 μm or more is removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com