Carbon fiber graphite tube with high strength, high transmit heat and its production method

A production method and carbon fiber technology, applied in the field of graphite tubes, can solve the problems of strength, heat transfer performance, unsatisfactory corrosion resistance, etc., and achieve the effects of strong corrosion resistance, superior heat transfer performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ① Ingredients mixing: Stir and mix 10% of superfine graphite powder over 200 mesh (eg 200 mesh, 300 mesh, 500 mesh) with 70% phenolic resin, 0.5% resin curing agent-benzenesulfonyl chloride, and 19.5% short carbon fiber Uniform;

[0024] ② Cake making: Make the above mixture into cake pieces in a commercially available cake making machine;

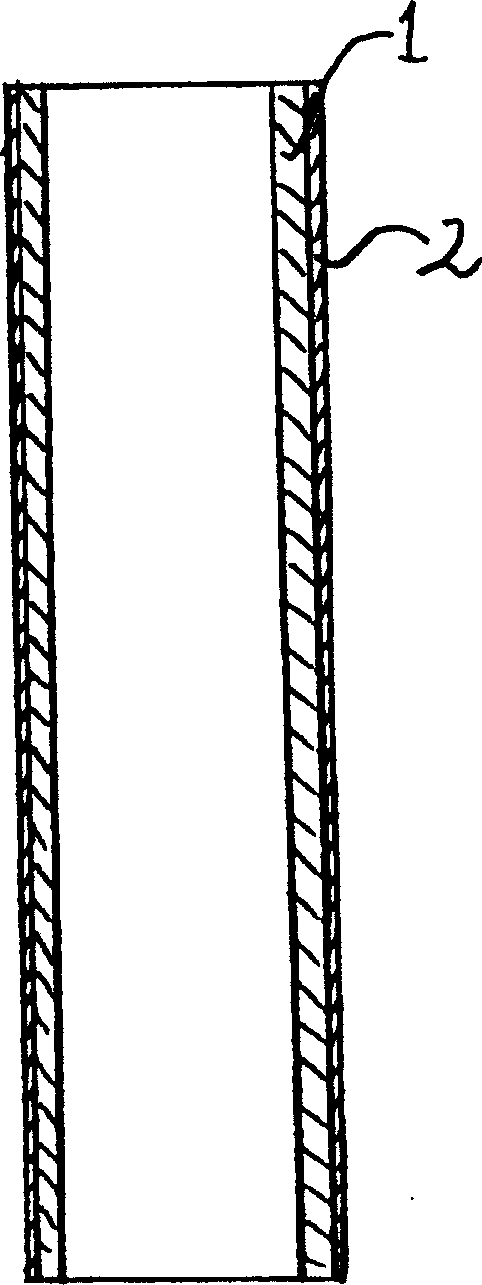

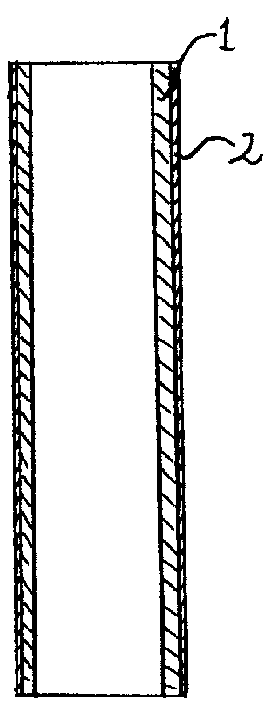

[0025] ③ pipe making; put the cake into a commercially available pipe making machine to make the pipe body 1;

[0026] 4. Winding carbon fiber layer: outside the pipe body 1 extruded from the pipe making machine, a layer of carbon fiber layer 2 is wound, and the weight of the carbon fiber layer 2 is equivalent to 5% of the weight of the graphite pipe body 1 . That is, a high-strength, high-heat-transfer carbon fiber graphite tube containing the above-mentioned components by weight is obtained.

Embodiment 2

[0028] When the ingredients were mixed, the weight ratio of each component was:

[0029] Graphite 17%, furfurone resin 53%, resin curing agent-ethyl sulfate 6%, short carbon fiber 23%;

[0030] When the carbon fiber layer is wound, the weight of the carbon fiber layer is equivalent to 3% of the weight of the graphite tube body.

[0031] All the other are the same as in Example 1.

Embodiment 3

[0033] When the ingredients were mixed, the weight ratio of each component was:

[0034] Graphite 25% PTFE resin 59% short carbon fiber 16%;

[0035] When the carbon fiber layer is wound, the weight of the carbon fiber layer is equivalent to 10% of the weight of the graphite tube body.

[0036] All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com