Efficient electric power generation method

A technology for heavy oil and crude oil, applied in combustion methods, engine components, machines/engines, etc., which can solve problems such as no processing burden, heat loss of exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

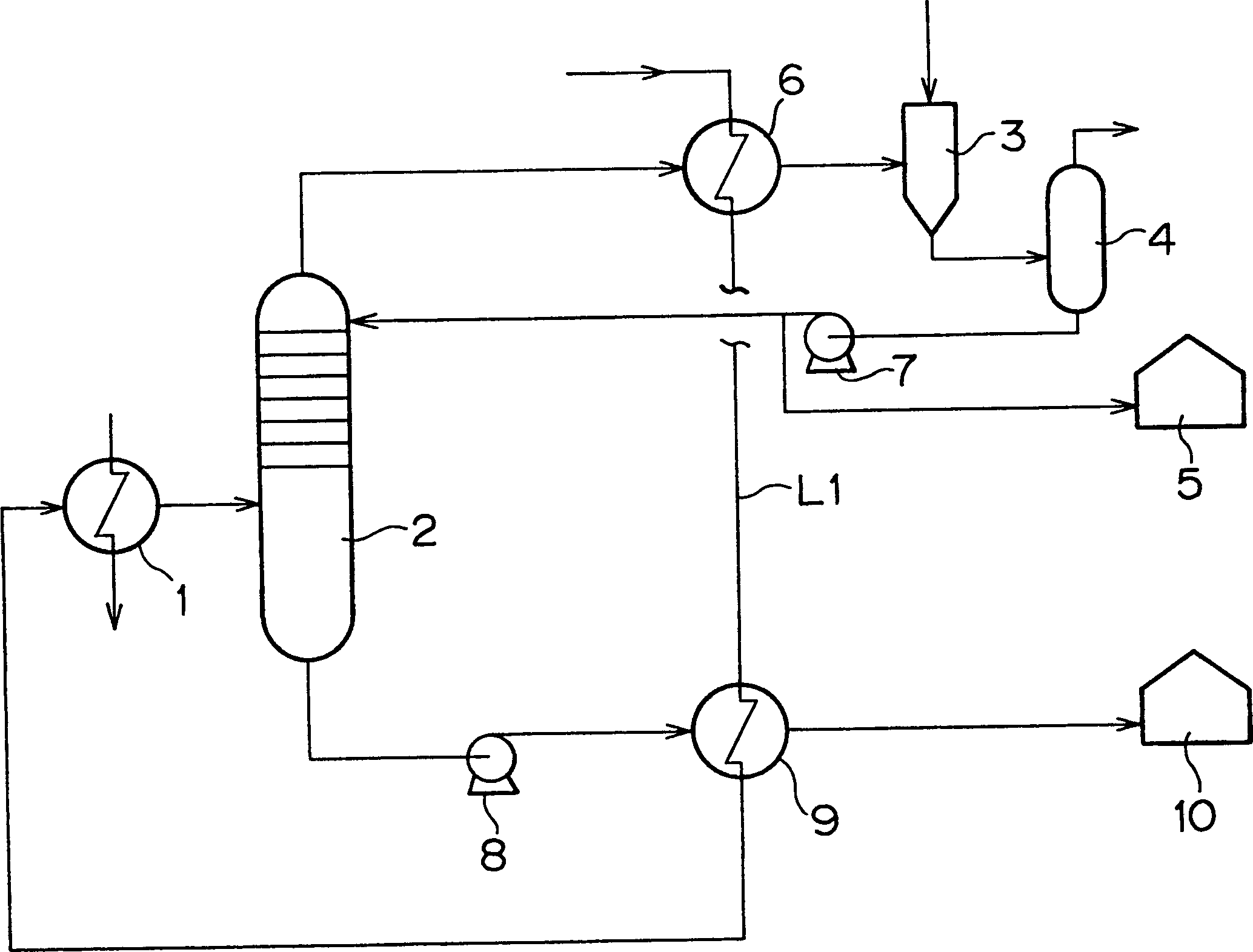

[0016] The high-efficiency power generation method of the present invention will be described below with reference to an embodiment shown in the accompanying drawings.

[0017] figure 1 is a schematic diagram showing the layout of an embodiment of a system for separating crude oil or heavy oil by distillation of a system for implementing the high-efficiency power generation method of the present invention by using an exhaust gas reburning system;

[0018] The distillation equipment of this embodiment includes a heater 1 , a vacuum distillation column 2 and a steam ejector 3 .

[0019] The heater 1 as a device for heating crude oil or heavy oil heats crude oil or heavy oil by heat exchange between steam and crude oil or heavy oil. Steam is supplied from a boiler (not shown). The steam obtained from the boiler is sent to a steam turbine to turn it, thereby generating electricity. The steam supplied to the heater 1 is the steam which once rotated the steam turbine to generate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com