Conditioner for polishing pad and method for manufacturing the same

A technology for polishing pads and regulators, applied in semiconductor/solid-state device manufacturing, wheels with flexible working parts, manufacturing tools, etc., and can solve the problems of wafer surface scratches, short circuits, and weakened bonding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

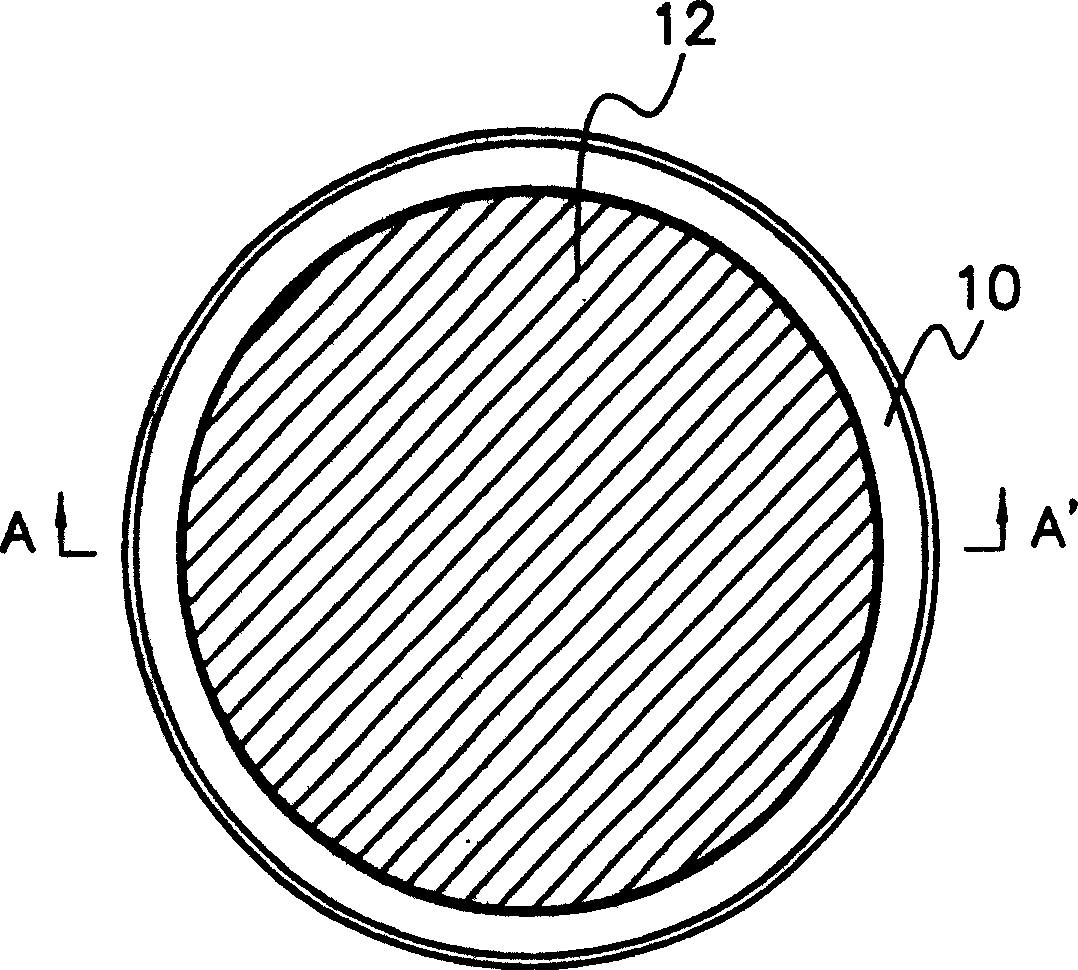

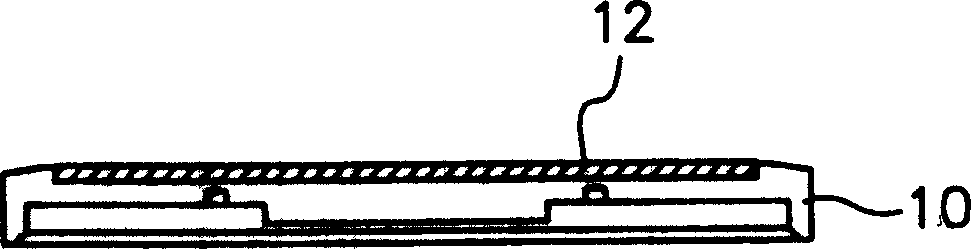

[0053] Figure 2A to Figure 2F A regulator having a disc shape according to a first preferred embodiment of the present invention is shown in , which regulator includes an integral part 20 , a cutting part 22 and a substrate 50 .

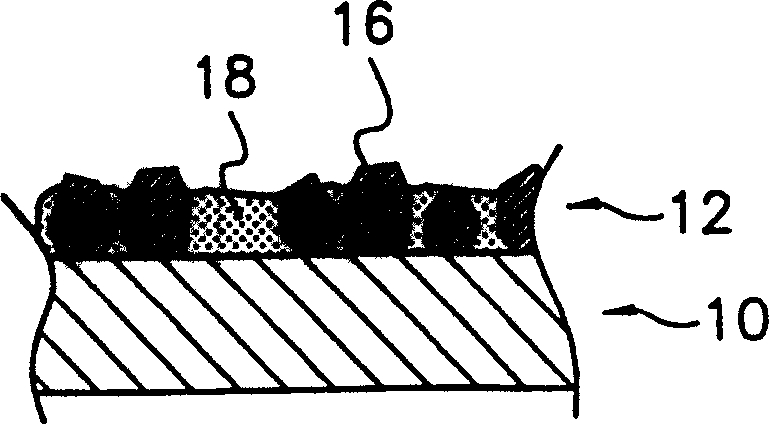

[0054] Such as Figure 2A to Figure 2D As shown, the cutting portion 22 has a large number of rectangular geometric protrusions 28 forming regional units in the form of cross-bands on the surface of the substrate 50, Figure 8A and Figure 8B are enlarged perspective and cross-sectional views in which the cross-band form of the rectangular geometric protrusions 28 of the cutting portion 22 is closely shown.

[0055] Substrate 50 is preferably made of a ceramic material such as Si or Si 3 N 4 . Or at least one ceramic material selected from the following group of ceramic materials, which include Al 2 o 3 , AlN, TiO 2 , ZrOx, SiO 2 , SiC, SiOxNy, WNx, Wox, DLC(diamond like coating), BN and Cr 2 o 3 . Alternatively, substrate 50 may be made ...

Embodiment 2

[0064] In this embodiment, various and optional arrangements of the geometric protrusions on the surface of the substrate can be realized by changing the arrangement and structure of the grooves. Such as Figure 2E As shown, grooves of the same shape may be formed on the cut portion 22a in the surface of the substrate with the same width and / or depth. Figure 7A and Figure 7B shown in the Figure 2EEnlarged perspective and cross-sectional views of the geometric protrusion arrangement formed by the grooves in . For this arrangement, it is preferable to make the groove 26a smaller than Figure 2A Grooves 26 are shown having a greater width and / or depth to effectively expel polishing pad debris from the surface of cutting portion 22a.

Embodiment 3

[0066] In this embodiment, various shapes of geometric protrusions can be realized. The shape of the geometric protrusion 28 is not limited to a rectangular shape, and alternatively, such as Figure 2F As shown, the geometric protrusion 28b formed on the cutting portion 22b has a cylindrical shape. Figure 9A and Figure 9B shows enlarged perspective and cross-sectional views with a cutting portion 22b formed by a cylindrical geometric protrusion 28b, similar to a substrate having a rectangular geometric protrusion, a substrate having a cylindrical geometric protrusion 28b on its cutting portion 22b is also There is a diamond layer 52 . The designed arrangement of the cylindrical geometric protrusions 28b can be in the same arrangement as the first and second preferred embodiments, or can be achieved by having a strip extending radially from the center of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com