Acid-proof high silicon cast iron and its manufacture process

A manufacturing method and a technology for high-silicon cast iron, which are applied in the field of high-silicon cast iron, can solve the problems of difficulty in applying production processes and increase production costs, and achieve the effects of cheap mass production and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

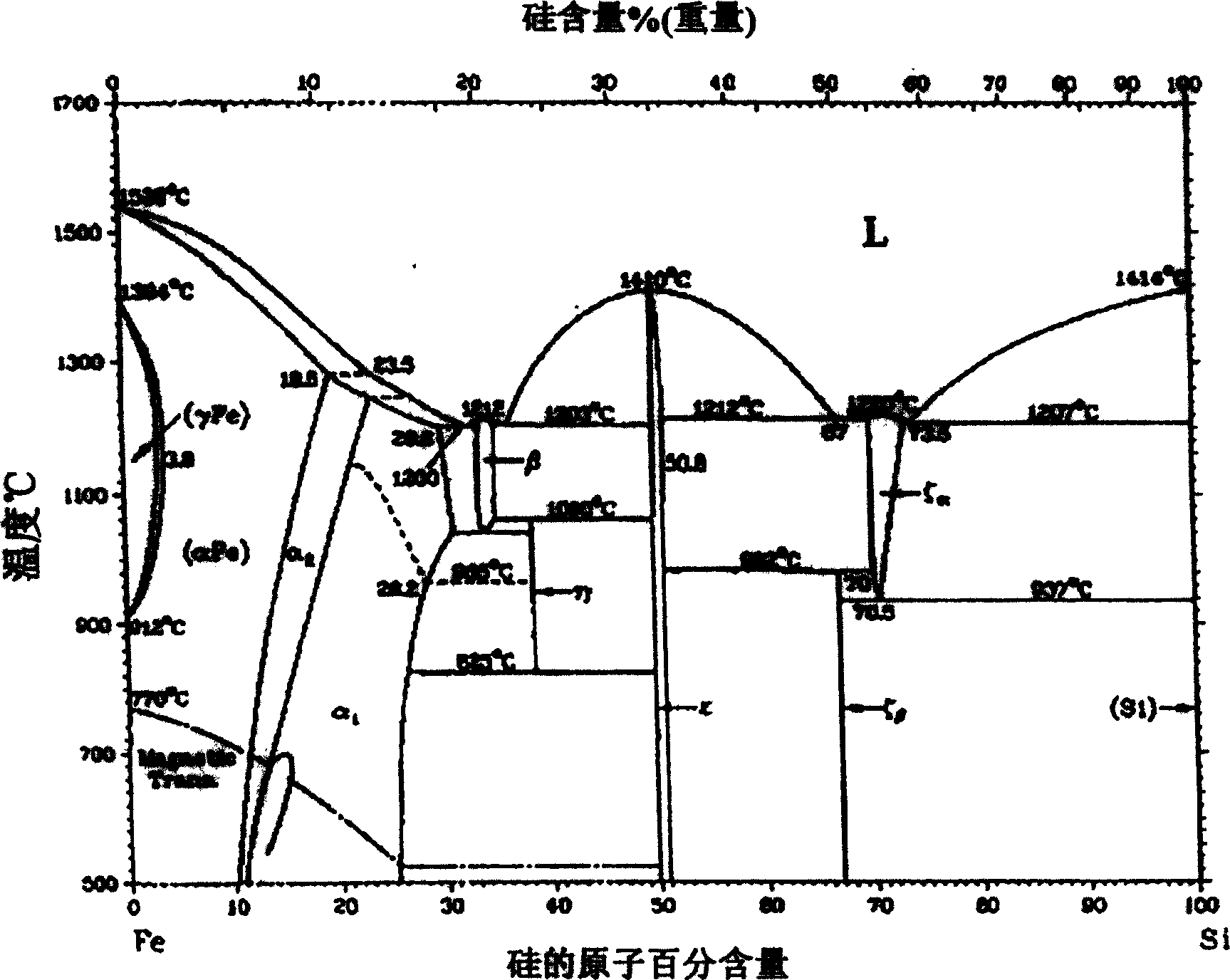

[0031] Generally, high-silicon cast iron has the disadvantage of being mixed with hydrogen to produce gas defects when it solidifies after pouring, resulting in very low tensile strength. In order to improve this point, a method of melting and pouring at a temperature of about 1400 ° C is now adopted after the master alloy is made by melting once, and then melted twice. However, in the case of using this method, 10kgf / mm cannot be obtained 2 above tensile strength. This is because the impurities contained in the silicon raw material cannot be completely removed, and inclusions are formed after casting.

[0032] Therefore, in the present invention, in order to remove impurities contained in the silicon raw material, a method of sufficiently removing impurities at 1650° C. or higher is employed. In the case of melting temperature below 1650°C in Table 1, that is, in comparative materials 1 to 9, such as Figure 3a As shown, it can be observed that there are inclusions on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com