Intelligent control method for reaction temp in liquid-phase oxidizing reactor of p-xylene

A technology of oxidation reactor and reaction temperature, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem that the controller design method is difficult to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

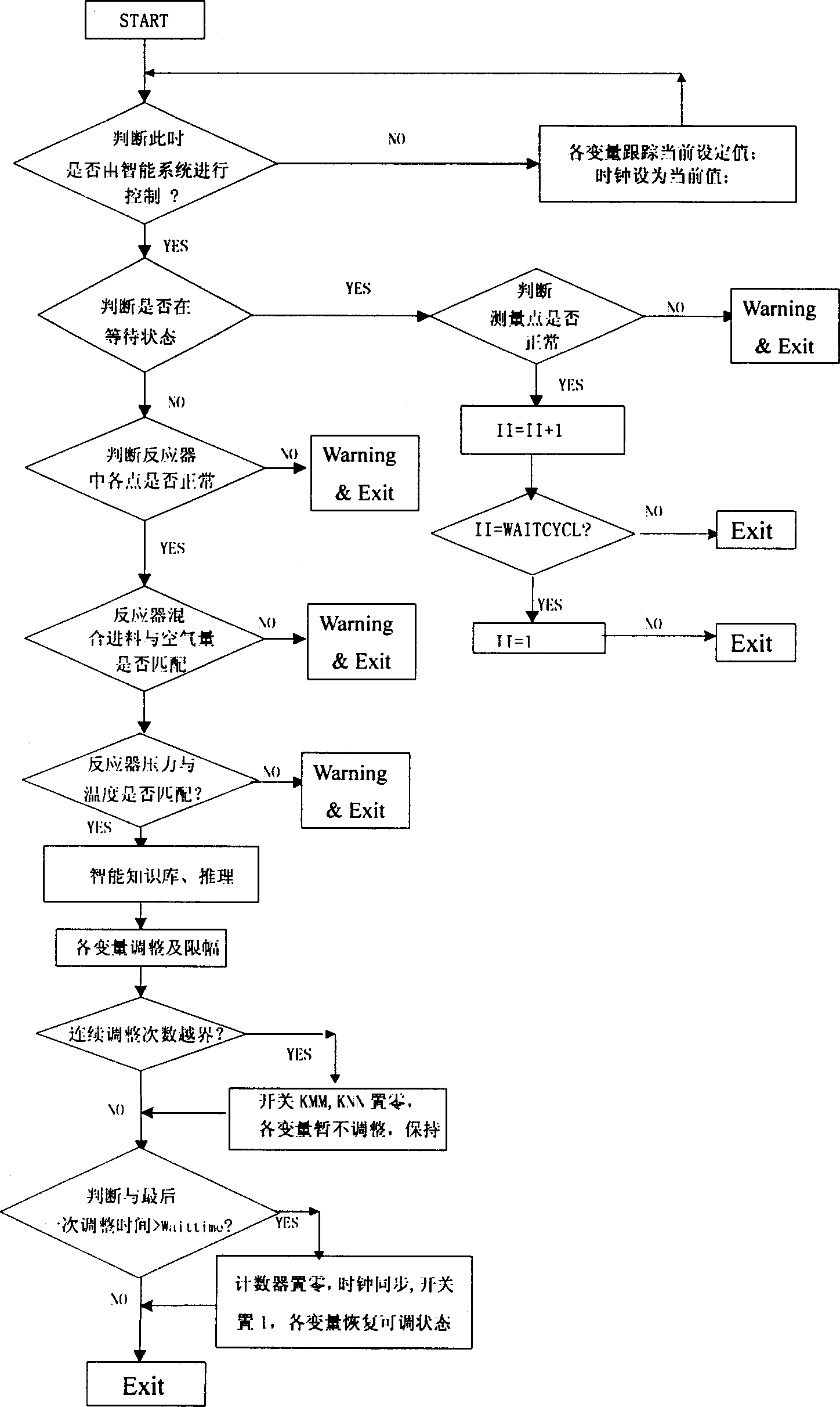

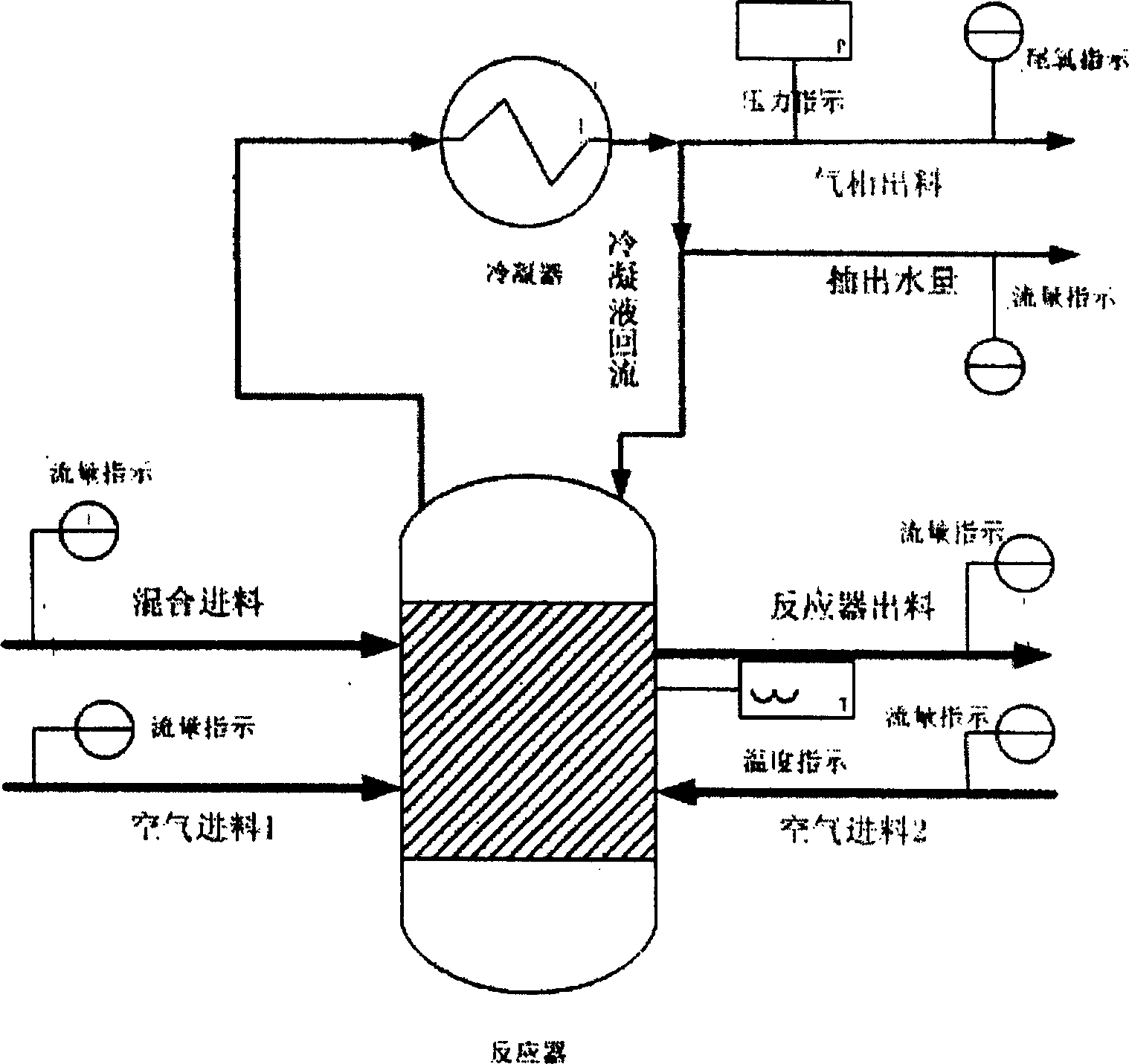

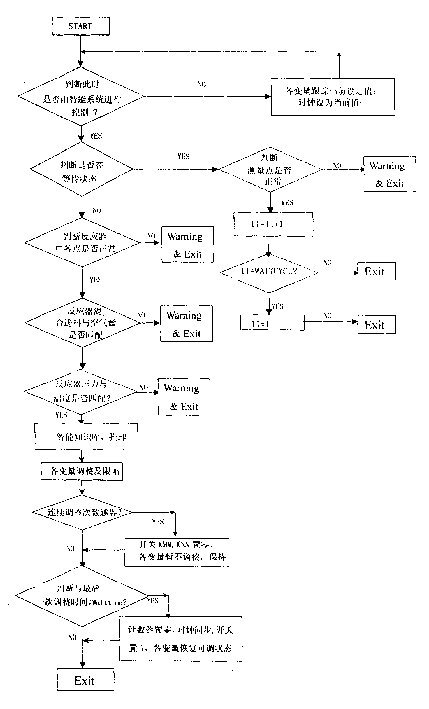

Method used

Image

Examples

Embodiment Construction

[0037] In the following table, when the reactor load changes, the intelligent control system itself can make judgments based on the heuristic knowledge solidified in the program. If the original knowledge and experience are changed, the human-machine interface of the intelligent control system can interface to communicate with the program. For example: the upper and lower limits of the extracted water, the upper and lower limits of the reaction temperature, the upper and lower limits of the tail oxygen concentration control, etc., can all be displayed in the parameter list of the intelligent controller.

[0038] T average (20mins)

Q average (20mins)

Intelligent control system output

∈[T_LO T_HI]

∈[Q_LO Q_HI]; normal range

The reactor is normal;

Each variable is kept;

∈[T_LO T_HI]

increase air volume;

Reaction pressure, pumped water volume maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com