Gold-silver alloy composite bonding wire and manufacturing method thereof

The technology of a gold-silver alloy and a manufacturing method, which is applied in the field of bonding wires, can solve the problems of high cost of bonding wires, low compressive strength, backward collecting devices and manufacturing processes, etc., and achieves less material consumption, cost saving, and good positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

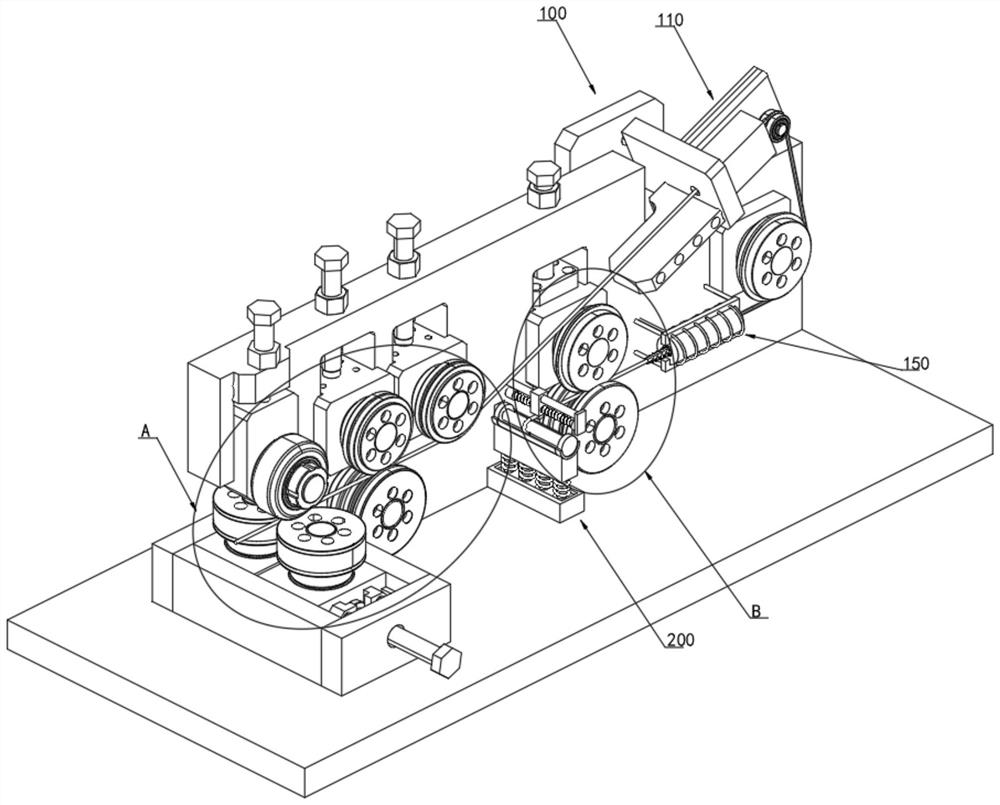

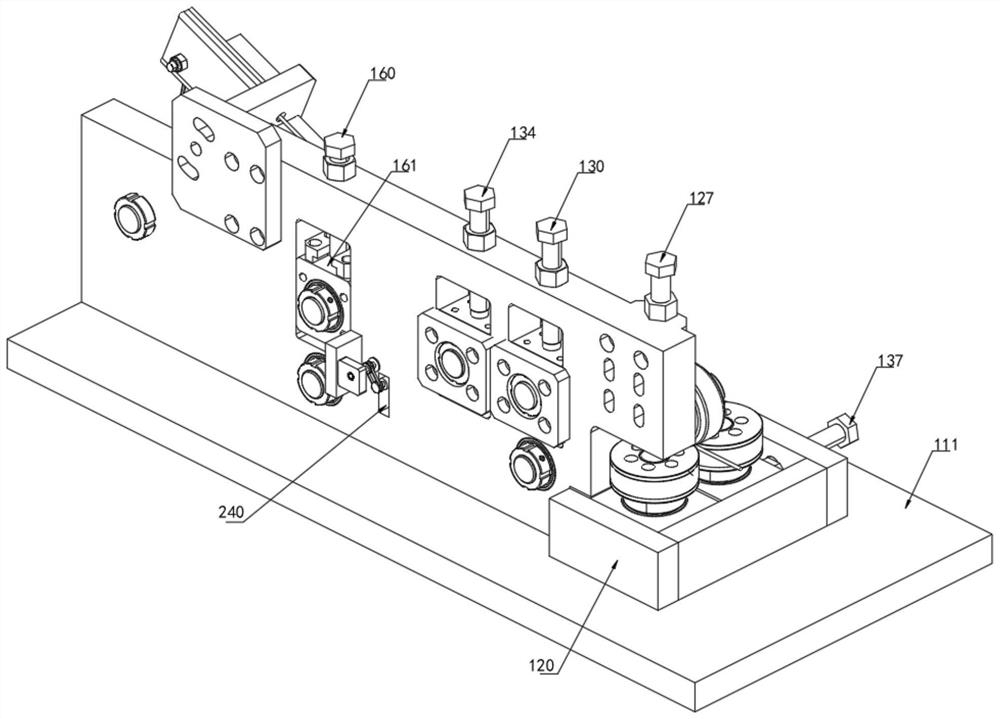

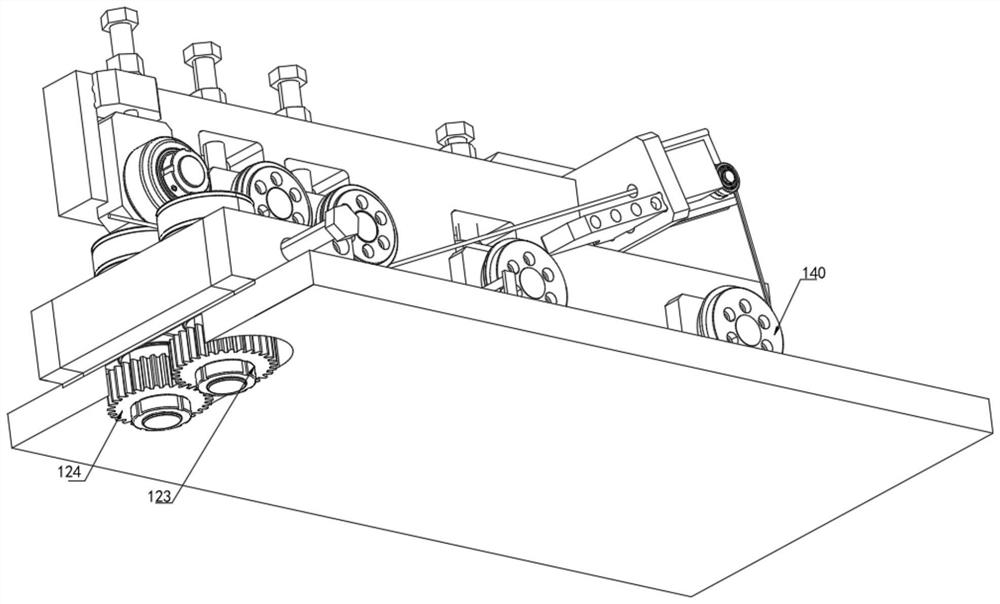

[0059] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0060] Refer to the attached Figure 1-10 , the present invention provides a gold-silver alloy composite bonding wire and a manufacturing method thereof, comprising a bonding wire matrix and a surface composite coating, the bonding wire matrix is a hexagonal prism, and the bonding wire matrix and the surface composite coating are composed of The overall shape is cylindrical, the outer diameter of the bonding wire substrate is 10-100 μm, and the thickness of the surface composite coating is 0.01-0.2 μm.

[0061] Further, the preparation method of the gold-silver alloy composite bonding wire comprises the following steps:

[0062] Step 1: melting and casting: the gold and silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com