Method for measuring magnesium element in steel by ICP-OES (Inductively Coupled Plasma-Optical Emission Spectrometer) method

A determination method and technology of magnesium element, applied in the field of chemical substance analysis, can solve the problems of cumbersome operation, difficult to control, high cost, and achieve the effects of reducing low results, fast dissolving samples, and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that, for those skilled in the art, several modifications and improvements can be made without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

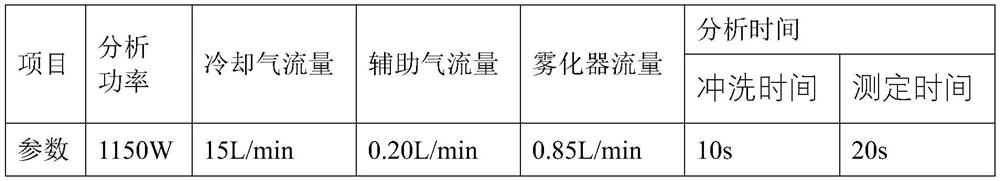

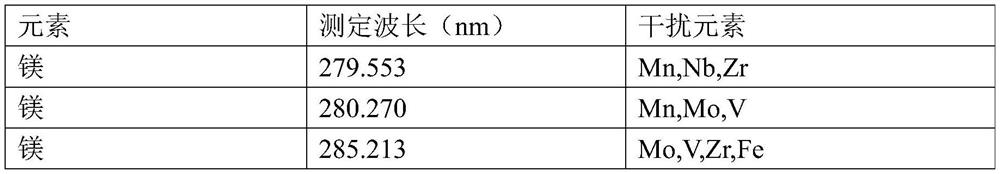

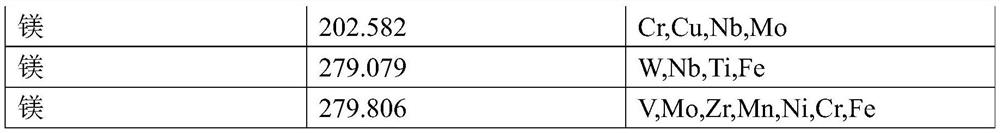

[0024] A kind of ICP-OES measures the determination method of magnesium element in steel, is specifically as follows:

[0025] 1. Equipment

[0026] 1.1. Thermo Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES): iCAP-6300

[0027] 1.2. LabTech cooling water circulation system: H150-1500

[0028] 1.3. Electronic balance: AL104

[0029] 1.4, Daojing laboratory ultrapure water machine

[0030] 1.5. Uninterruptible Power Supply (UPS): 20kVA

[0031] 2. Reagents

[0032] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com