Mine water source waste heat recycling hot water bathing system

A waste heat recovery and mine water technology, applied in heat recovery systems, residential hot water supply systems, heat collectors using groundwater as the working fluid, etc., can solve low heat exchange efficiency, high overall operating costs, large heat loss, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

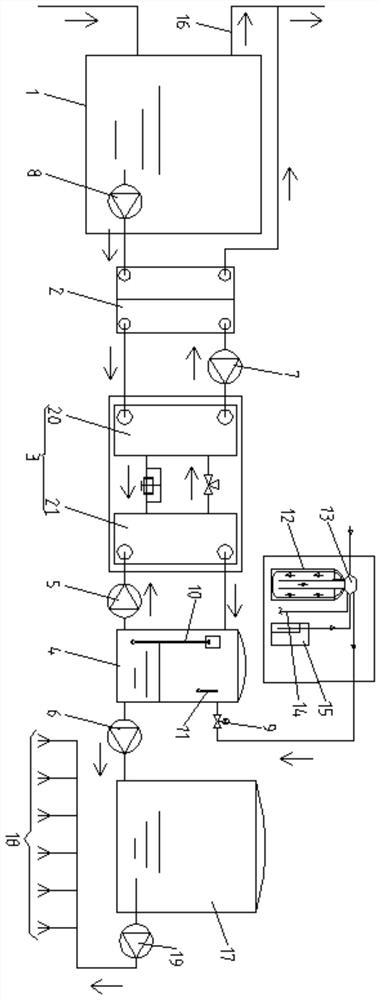

[0037] like figure 1 As shown, this embodiment provides a mine water source waste heat recovery and utilization hot water bathing system, including a mine water reservoir 1, a heat exchanger 2, a heat pump unit 3 and a water storage tank 4, and the heat pump unit 3 is provided with interconnected Interface 1, interface 2 and interconnected interface 3 and interface 4; the water outlet, interface 3, interface 4 at the bottom of the water storage tank 4 and the water inlet at the top of the water storage tank 4 are connected in turn through pipelines to form a circulation loop, and the water storage tank 4. A circulating water pump 5 is fixedly installed on the pipeline between the water outlet and the interface 3; the bathing opening at the bottom of the water storage tank 4 is connected with one end of the bathing pipeline, and a turning pump 6 is fixedly installed on the bathing pipeline;

[0038] The heat exchanger 2 is provided with the interconnected interface five and the...

Embodiment 2

[0045] On the basis of Embodiment 1, this embodiment further includes a water softener processor, which is communicated with the water storage tank 4 through a water replenishment pipeline, and a control valve-9 is fixedly installed on the replenishment pipeline.

[0046] When working, it is necessary to replenish water to the water storage tank 4 regularly. During the replenishment process, the tap water is softened by a water softener to remove the calcium and magnesium plasma in the tap water, and the tap water with high salinity is converted into softened water to avoid the inside of the equipment. fouling, so as to avoid affecting the heat exchange efficiency and water flow transmission, and ensure the heating efficiency of the entire system.

Embodiment 3

[0048] On the basis of Embodiment 2, this embodiment also includes a controller. The water storage tank 4 is fixedly installed with a liquid level controller 10 and a thermometer 11. The liquid level controller 10, the thermometer 11, the control valve 1 9 and the heat pump unit 3 respectively communicate with the controller.

[0049] When working, the temperature of the water in the water storage tank 4 is monitored in real time through the thermometer 11, and the corresponding temperature signal is sent to the controller, and the controller receives the corresponding temperature signal and judges and analyzes; when the water temperature in the water storage tank 4 reaches 43 ℃ At the time, the controller turns off the heat pump unit 3, and the controller starts the turning water pump 6, and the turning water pump 6 sends out the water in the water storage tank 4 for bathing;

[0050] At the same time, the water level in the water storage tank 4 is monitored in real time by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com