Slump-retaining concrete water reducing agent and preparation method thereof

A technology of concrete water reducer and water reducer, which is applied in the field of concrete admixtures, can solve the problems of reduced dispersion performance and dispersion retention performance, reduced concrete workability, excessive concrete loss, etc., and achieves the suppression of early calcium hydroxide. Generates, enhances mechanical strength, and maintains long-term fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

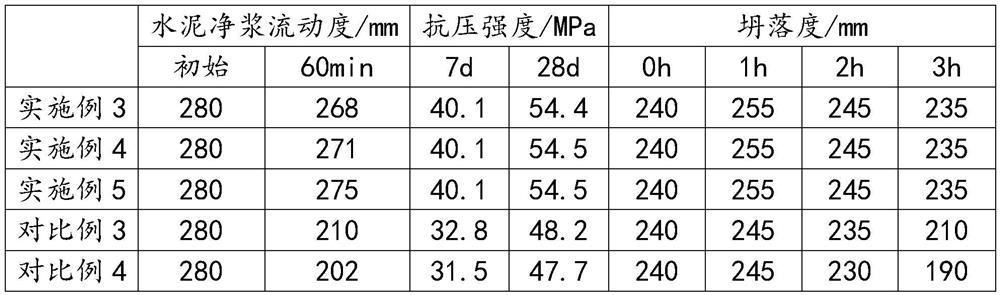

Examples

Embodiment 1

[0029] Preparation of branched monomers:

[0030] Step S21, mixing itaconic acid and toluene, adding a Custer catalyst, stirring for 30 min, then adding tetramethyldisiloxane, continuing to stir the reaction for 48 h, and concentrating under reduced pressure after the reaction to remove the solvent to obtain a carboxyl monomer; The dosage ratio of peronic acid, tetramethyldisiloxane and Custer catalyst is 0.02mol:0.01mol:0.4mL;

[0031] Step S22 , under nitrogen protection, mix the carboxyl monomer and N,N-dimethylacetamide, add triethanolamine and p-toluenesulfonic acid, and react at 140° C. for 6 hours to obtain a branched monomer. The mass ratio of carboxyl monomer, triethanolamine and p-toluenesulfonic acid is 26:29:1.

Embodiment 2

[0033] Preparation of branched modified water reducing agent:

[0034] Step S11, mix methallyl polyoxyethylene ether and deionized water, set the temperature to 60°C, add maleic anhydride, stir for 10 min, add acrylic acid, diethyl vinylphosphonate, monomer c and ammonium persulfate , after the dropwise addition, the temperature was raised to 75°C, and the branched monomer prepared in Example 1 was added. After the addition, the temperature was kept unchanged, and the reaction was kept for 4h; the polymerization product was obtained; methallyl polyoxyethylene ether, Maleic anhydride, acrylic acid, diethyl vinylphosphonate and sodium methacrylic acid sulfonate are used in a molar ratio of 1:0.6:1.6:1.2:0.8; the addition amount of ammonium persulfate is methallyl polyoxyethylene ether 0.4% of the mass, and the added amount of branching monomers is 40% of the mass of methallyl polyoxyethylene ether.

[0035] Step S12, under nitrogen protection, mix the polymer product obtained i...

Embodiment 3

[0037] A preparation method of a slump-preserving concrete water reducing agent, comprising the following steps:

[0038] In parts by weight, 80 parts of the branched modified water-reducing agent prepared in Example 2, 2 parts of PEG400, 8 parts of sodium lignin sulfate, and 60 parts of water were mixed to obtain a slump-preserving concrete water-reducing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com