Preparation method of corn alcohol-soluble protein nanofiber membrane used for cell culture

A technology of zein and nanofiber membranes, which is applied in tissue cell/virus culture devices, biochemical equipment and methods, fiber treatment, etc., can solve the problem of poor mechanical properties, difficult removal of chemical reagents, and effects on zein Fiber biocompatibility and other issues, to achieve the effect of improved mechanical strength, simple and effective preparation method, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

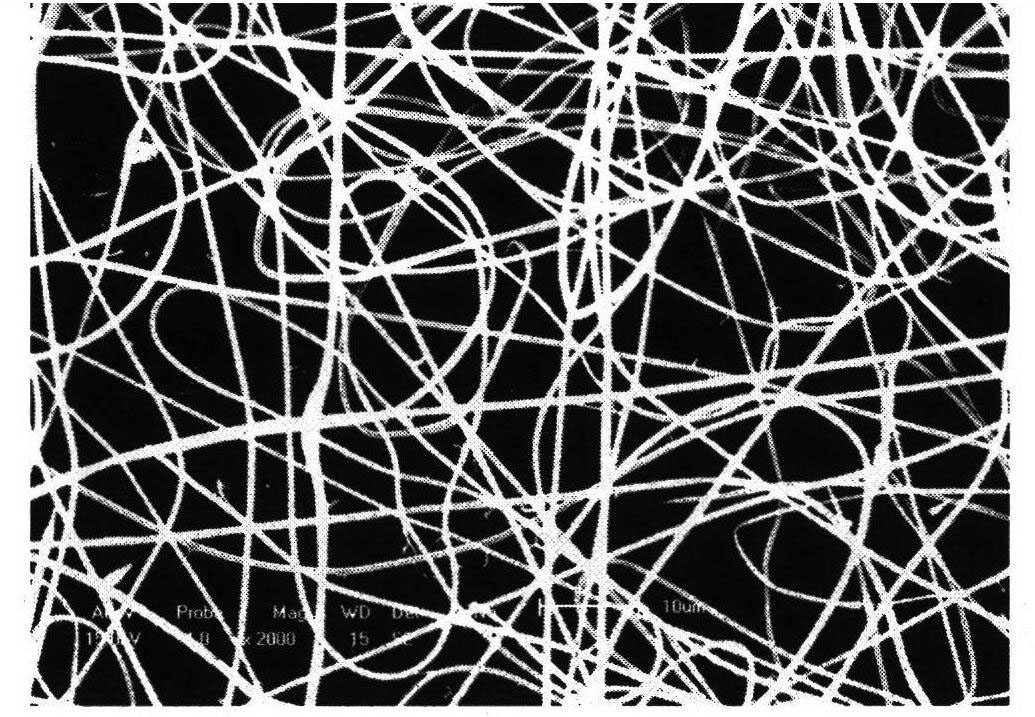

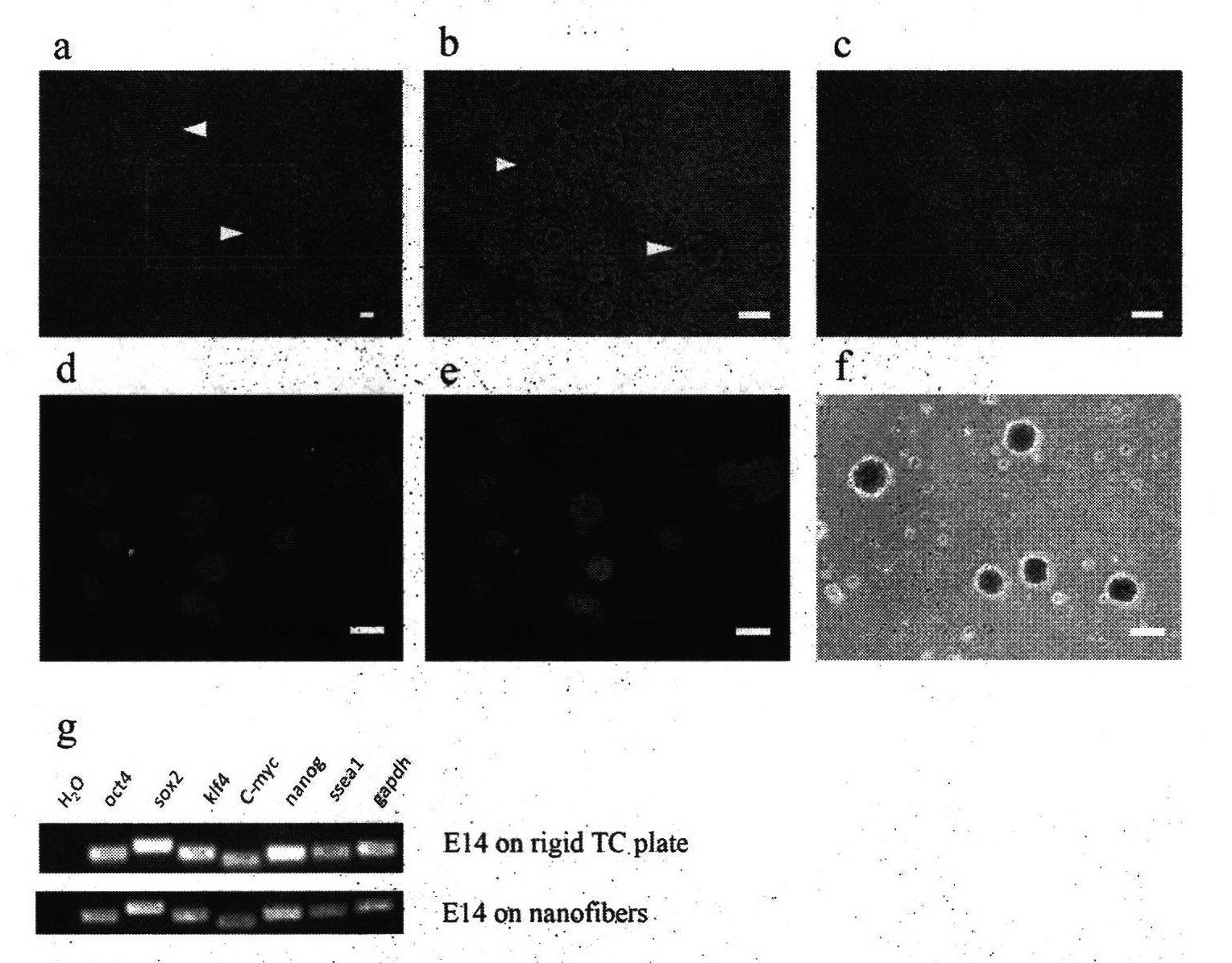

[0024] Dissolve 1.5-4.0 grams of zein in a mixed solvent of 10 ml ethanol and water, the volume ratio of ethanol and water is 80:20, 70:30, 60:40 to form 15%-40% (w / v) Then add it into a plastic syringe, the syringe is connected to a high-voltage positive electric field, the distance between the nozzle and the receiver is controlled at 15cm-25cm, the solution flow rate is 0.5mL / h-2mL / h, the voltage is 10kV-18kV, and electrospinning is carried out. , the nanofibers with ribbon structure were obtained, and the nanofibers stacked randomly into a zein nanofiber film.

Embodiment 2

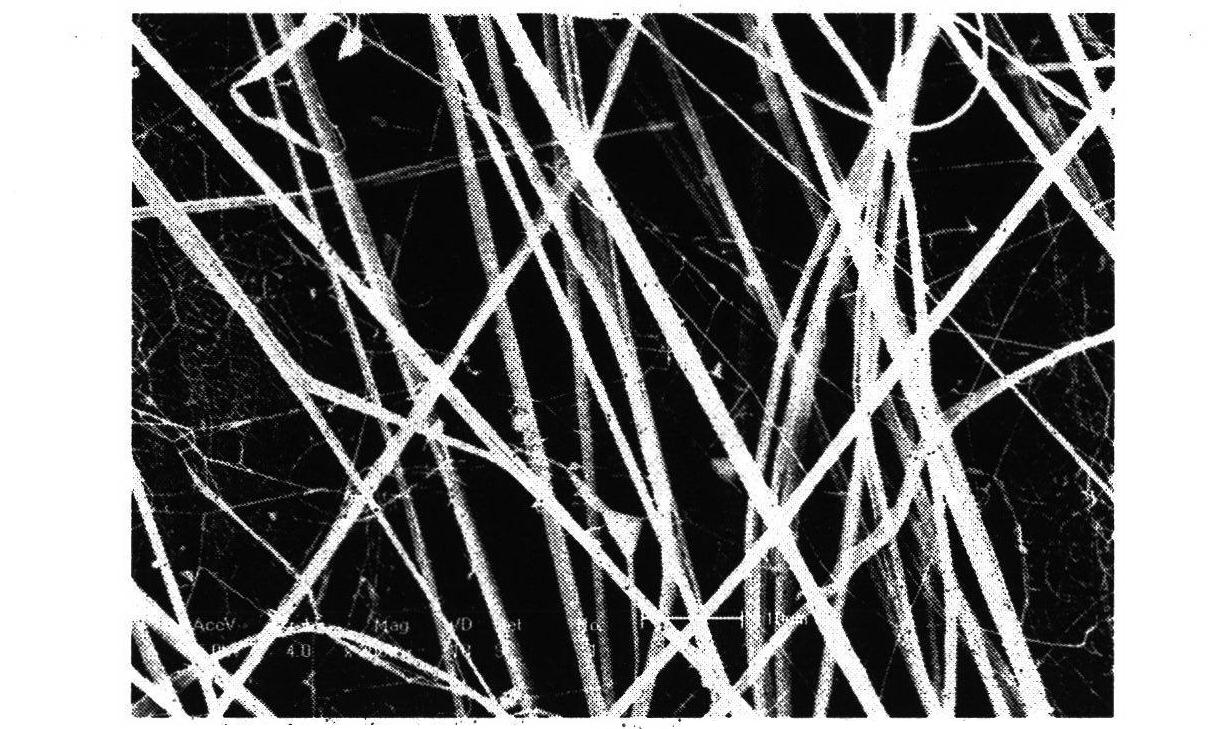

[0026] Dissolve zein in the mixed solvent of 10ml ethanol and water, the volume ratio of ethanol and water is 70:30, then add polyvinyl alcohol, the mass ratio of zein and polyvinyl alcohol is 5:1,4 : 1, 3: 1, 2: 1, 1: 1, magnetically stirred at 80°C for 12 hours, made into a polymer solution with a mass concentration of 15%, and then added to a plastic syringe, the syringe was connected to a high-voltage positive electric field, and the injection head and the receiver The distance between objects is controlled at 15cm-25cm, the solution flow rate is 0.5mL / h-2mL / h, and the voltage is 0kV-18kV. Electrospinning is performed to obtain a nanofiber membrane with greatly improved mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com