High-compaction-density and high-rate-performance graphite negative electrode material and preparation method thereof

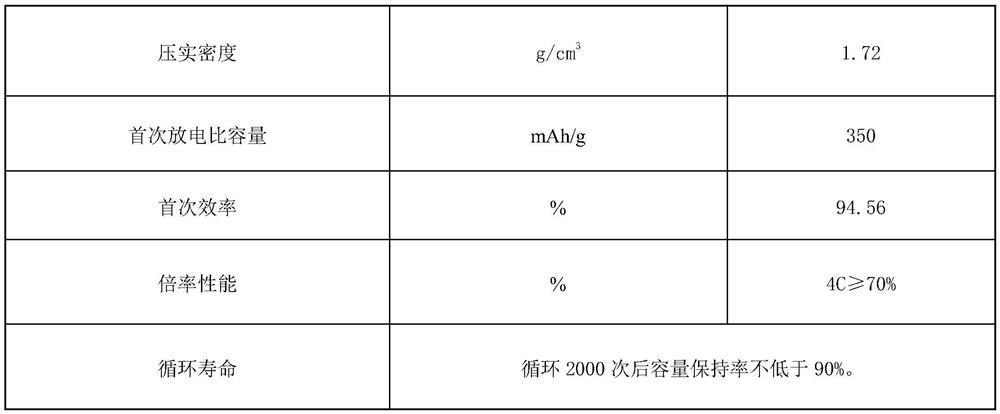

A graphite negative electrode and high-magnification technology, which is applied in chemical instruments and methods, battery electrodes, carbon compounds, etc., can solve the problems of long entry and exit paths of lithium ions, low material compaction density, and high manufacturing costs, and achieve rapid improvement. Charge and discharge performance, avoid collapse of graphite structure, and improve cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

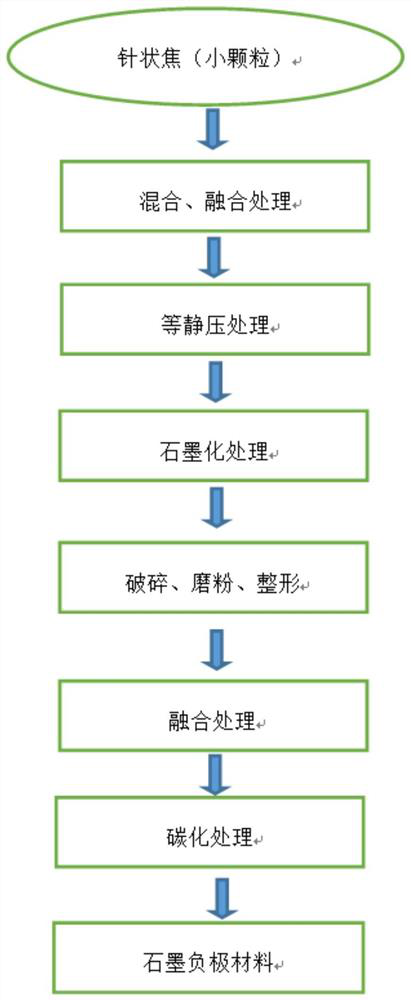

[0028] like figure 2 As shown in the present invention, the method for preparing a graphite negative electrode material with high compaction density and high rate performance includes the following main steps: grinding coal-based needle coke powder to obtain small particles, and then mixing with medium-temperature petroleum-based asphalt micropowder through VC. Machine mixing and fusion machine treatment to obtain the fused material, and then subjected to isostatic pressing and graphitization treatment, and the graphitized block is crushed, pulverized, and shaped to obtain isotropic secondary graphite particles. Finally, the isotropic secondary graphite particles and the high softening point pitch are mixed and fused, and then carbonized to obtain the graphite negative electrode material. The specific preparation method is as follows:

[0029] Step 1: mixing the pulverized coal-based needle coke with medium-temperature petroleum pitch to obtain a mixed powder, wherein the me...

Embodiment

[0043] Step 1: Mix the milled needle coke with a particle size of 5 μm and a medium-temperature petroleum-based asphalt (softening point of 120° C.) with a particle size of 3 μm in a VC mixer for 40 minutes.

[0044] Step 2: The mixed powder is subjected to fusion treatment, and the fusion time is 20min.

[0045] Step 3: The fused material is subjected to liquid isostatic pressure treatment with a pressure of 150MPa; the treatment time is 30min.

[0046] Step 4: The block after isostatic pressing is subjected to graphitization treatment at a temperature of 2900° C. and a graphitization treatment time of 48 hours.

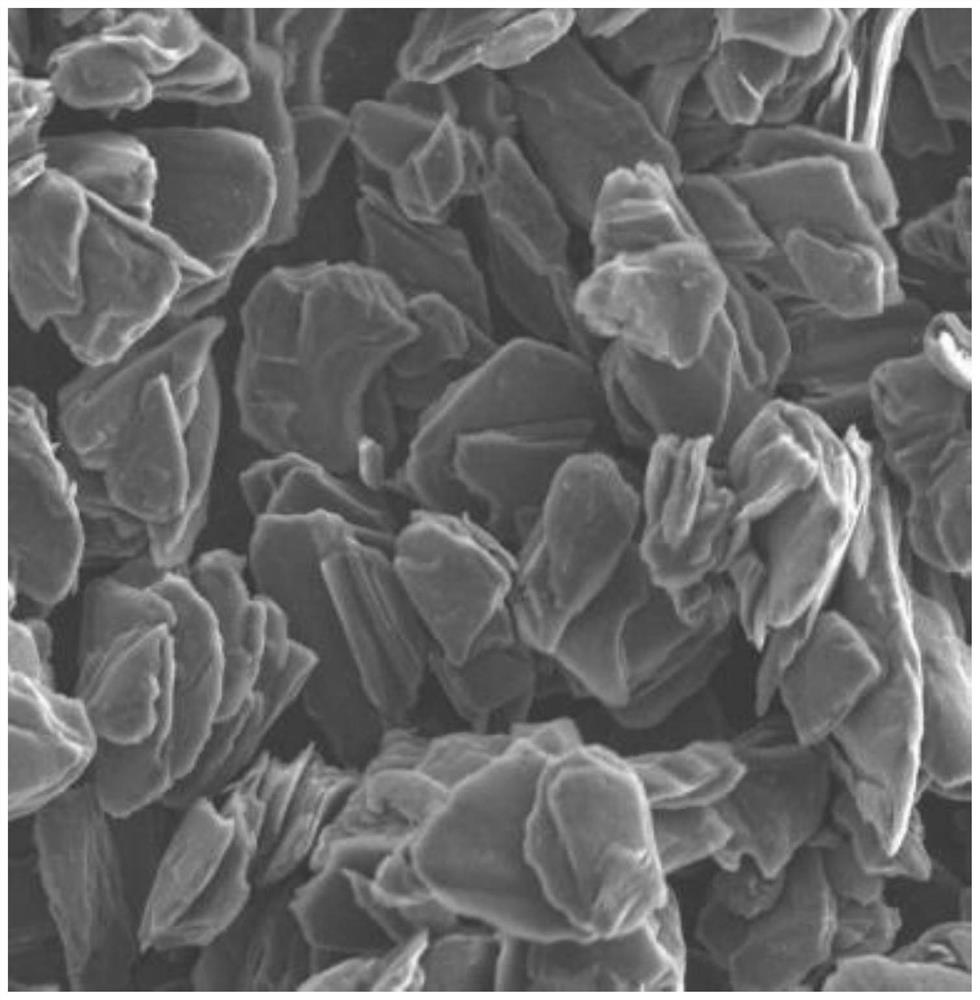

[0047] Step 5: The above graphitized block is then crushed, pulverized and shaped to obtain isotropic graphite secondary particles with an average particle size of 16 μm.

[0048] Step 6: Mixing, fusing and carbonizing the isotropic graphite secondary particles and high softening point pitch. The high softening point pitch is 200°C; the fusion time is preferably 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com