Quantitative feeding device for metal powder machining

A technology of quantitative feeding and metal powder, applied in the field of metal powder processing, can solve the problems affecting the effect of compact forming of parts, and achieve the effect of enhancing the effect of back blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

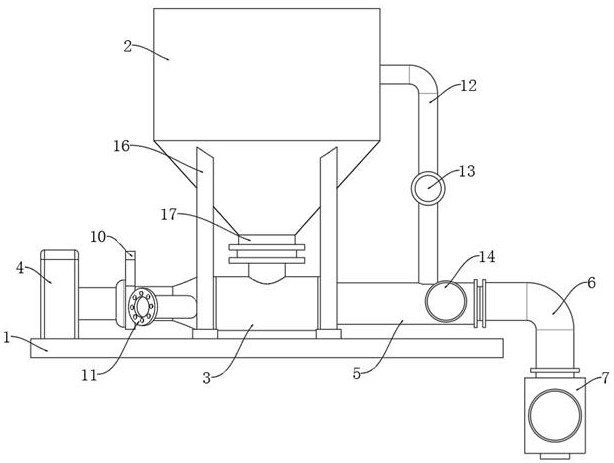

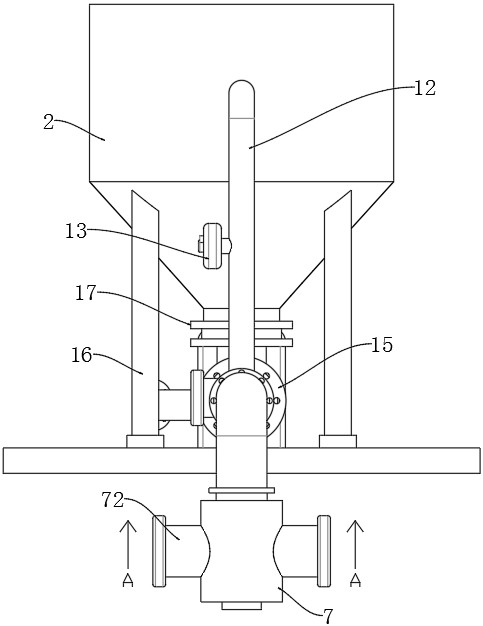

[0032] like Figure 1 to Figure 4 As shown in the figure, a quantitative feeding device for metal powder processing according to the present invention includes a silo 2 installed on the bottom plate 1, and also includes a feeding pipe 3 arranged under the silo 2. One end of the feeding pipe 3 is provided with There is an air pump 4, the other end of the feeding pipe 3 is provided with a feeding pipe 5, the end of the feeding pipe 5 away from the feeding pipe 3 is connected with the arc-shaped pipe 6, and the end of the arc-shaped pipe 6 away from the feeding pipe 5 is provided with an upper Material cavity 7;

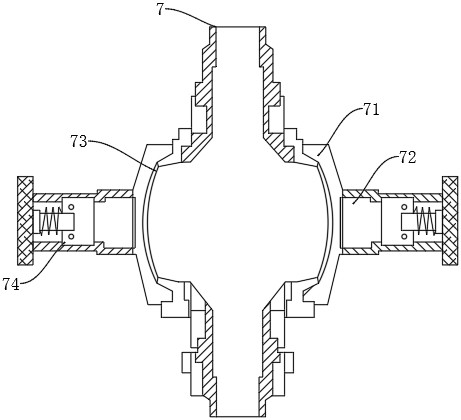

[0033] The feeding cavity 7 includes an inner wall and an outer wall, and there is a space between the inner wall and the outer wall for installing the external expansion joint 71. The outer wall of the feeding cavity 7 is provided with an external expansion cavity 72. The outer wall is connected with the outer expansion joint 71 through, and the inner wall of the feed...

Embodiment 2

[0052] The difference from Example 1 is that:

[0053] like Figure 5 to Figure 6 As shown, the inner wall of the feeding cavity 7 is composed of two sets of upper and lower shrink films 73, and the upper and lower sets of shrink films 73 are connected by a ring-shaped connecting block. The upper and lower closed spaces are formed into two upper and lower closed spaces and correspond to the upper and lower two groups of shrink films 73 respectively, and both upper and lower closed spaces are provided with a cam 751 and a sliding rod 752. The two cams 751 are connected by the connecting shaft 9, and the upper The length of the sliding rod 752 is smaller than the length of the sliding rod 752 below.

[0054] In actual operation, it is found that the metal powder accumulation density inside the feeding cavity 7 is also different. Since the interior of the feeding cavity 7 near the lower outlet is closest to the external environment, when the moisture in the external environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com