High-strength anti-seismic wide-body gravity dam structure and construction method thereof

A gravity dam and wide-body technology, applied in gravity dams, foundation structure engineering, filling, etc., can solve problems affecting construction efficiency, inconvenient transportation and assembly of new dam bodies, and inconvenient overall construction of new dam body formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

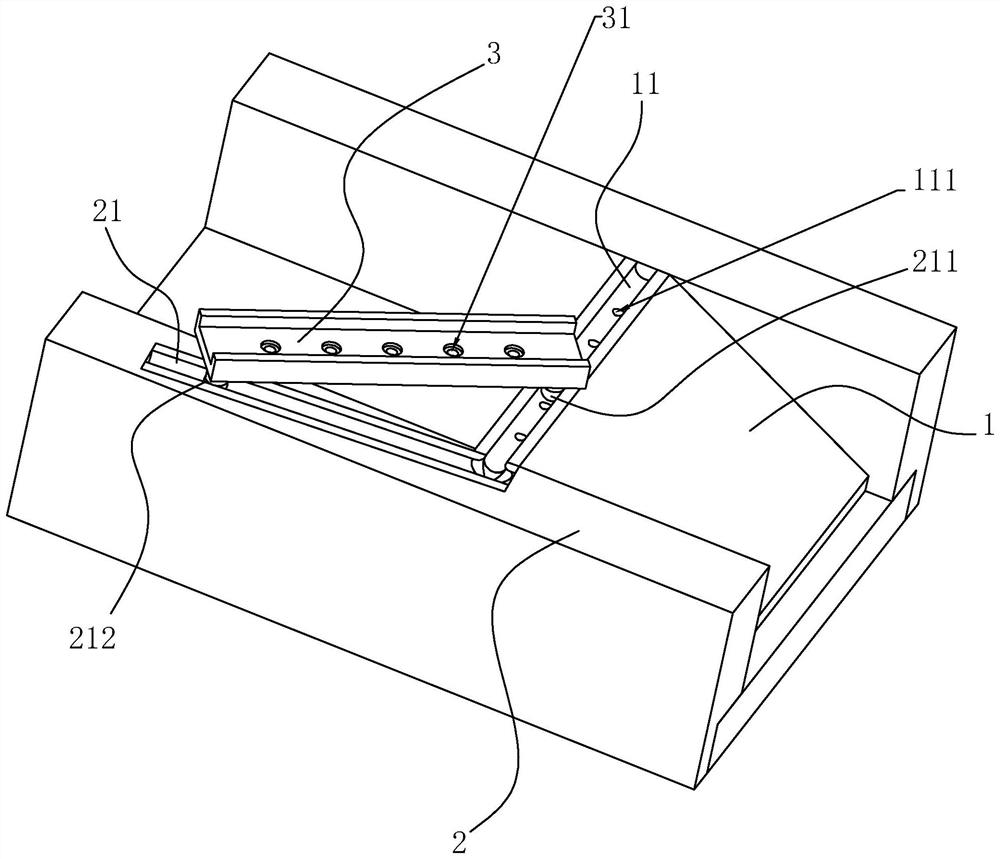

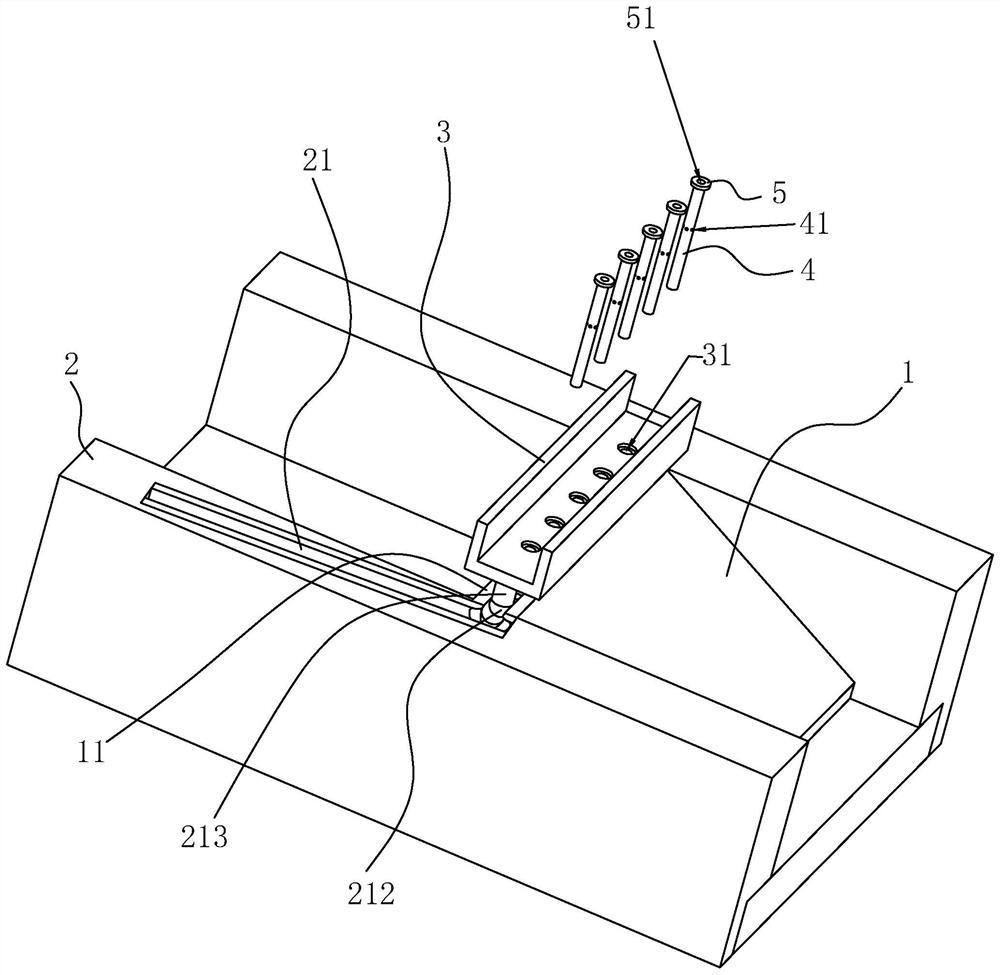

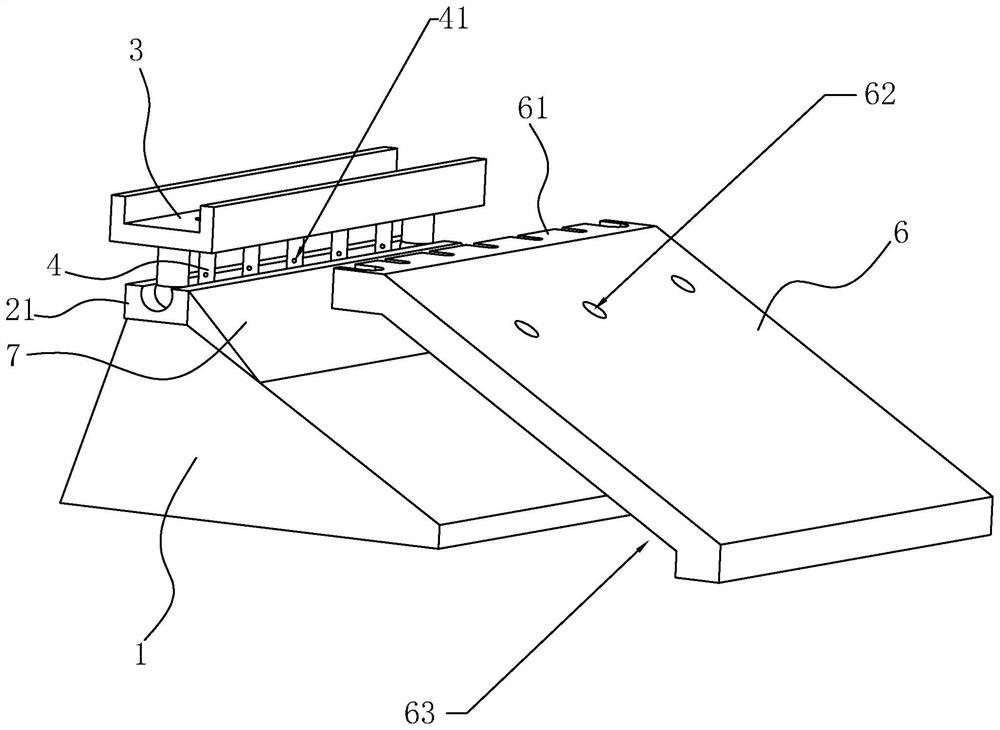

[0033] Attached to the following Figure 1-4 The present invention will be described in further detail.

[0034] The embodiment of the present invention discloses a high-strength earthquake-resistant wide-body gravity dam structure and a construction method thereof, refer to figure 1The high-strength earthquake-resistant wide-body gravity dam structure includes a first guide rail 11 , a second guide rail 21 and a first prefabricated body 3 . The first guide rail 11 and the second guide rail 21 have the same structure, the vertical section is concave, and the inner wall is a circular arc surface. Among them, the first guide rail 11 is pre-buried on the top of the old dam body 1; the second guide rail 21 is pre-buried on the road surface of the mountain road 2, the second guide rail 21 and the first guide rail 11 communicate with each other, and the first guide rail 11 and the second guide rail 21 The included angle is 115°.

[0035] The first prefab 3 is concave and the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com