Water-soluble nonionic polymer viscosity reducer as well as preparation method and application thereof in viscosity reduction of extra-heavy oil

A non-ionic polymer and water-soluble technology, which is applied in drilling compositions, chemical instruments and methods, and bulk chemical production, can solve problems such as poor temperature resistance, poor viscosity reduction effect, and difficult demulsification, and achieve Provides viscosity-reducing performance, simple preparation method, and good adaptability to formation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

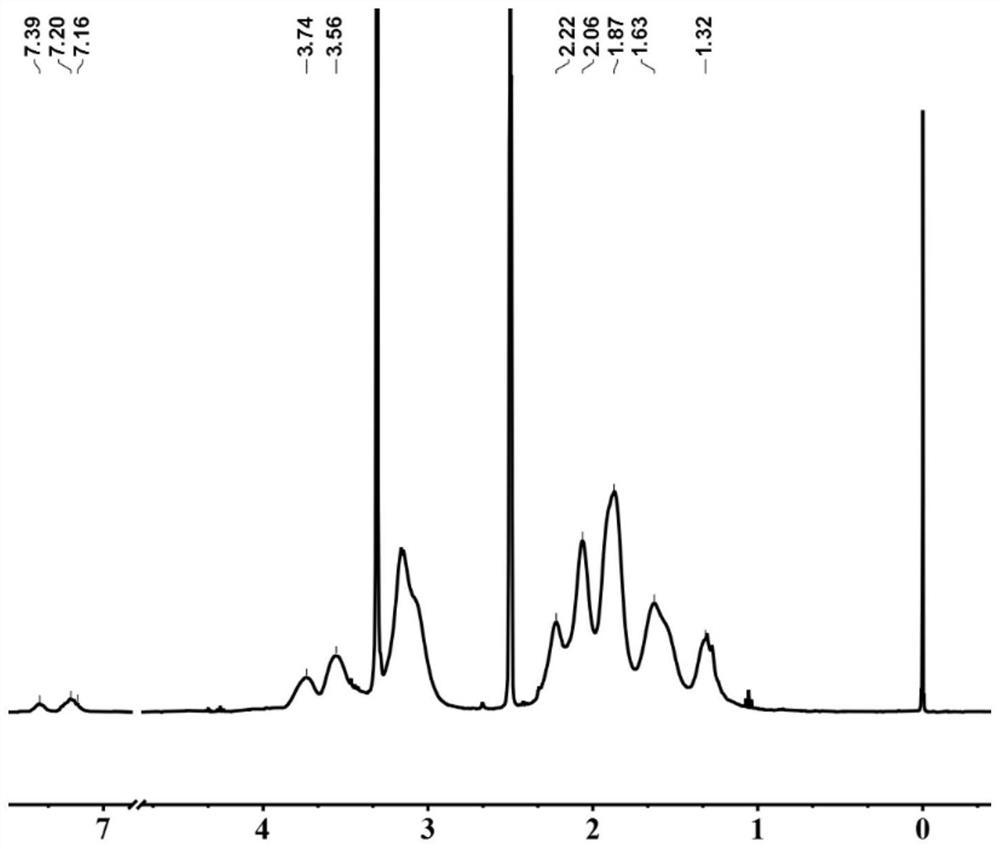

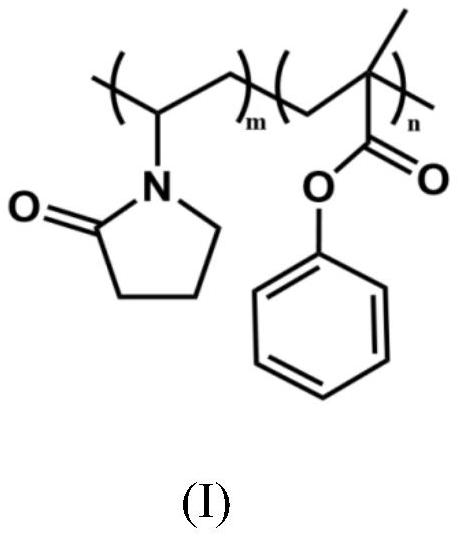

Image

Examples

Embodiment 1

[0035] A preparation method of a water-soluble nonionic polymer viscosity reducer, comprising the steps of:

[0036] (1) 2.464 g of N-vinylpyrrolidone and 0.04 g of phenyl methacrylate were dissolved in 14 mL of toluene, and the molar ratio of N-vinylpyrrolidone to phenyl methacrylate in the system was 98.9:1.1.

[0037] (2) Pass nitrogen and deoxygenate into the above obtained system for 30min, add 0.0251g of azobisisobutyronitrile, and conduct radical polymerization at 80°C for 10h to obtain a light yellow viscous liquid; after dissolving it in ethanol, use molecular weight cut-off The 1000D dialysis bag was dialyzed in ethanol for 72 hours, then rotary evaporated to remove the solvent, and then placed in a vacuum drying oven for drying at 60 °C for 18 hours to remove excess ethanol to obtain a light yellow transparent solid, which is a water-soluble non-ionic polymer. Adhesive, its weight average molecular weight is 1.094×10 4 .

Embodiment 2

[0039] The preparation method of a water-soluble nonionic polymer viscosity reducer is as described in Example 1, the difference is: the amount of N-vinylpyrrolidone used in step (1) is 2.081g, toluene is 12mL, and N-ethylene The molar ratio of pyrrolidone to phenyl methacrylate is 98.7:1.3; 0.0212g of azobisisobutyronitrile is added in step (2); the weight-average molecular weight of the obtained water-soluble nonionic polymer viscosity reducer is 1.133×10 4 .

Embodiment 3

[0041] The preparation method of a water-soluble nonionic polymer viscosity reducer is as described in Example 1, except that the amount of N-vinylpyrrolidone used in step (1) is 1.800 g, toluene is 10.16 mL, and N- The molar ratio of vinylpyrrolidone to phenyl methacrylate is 98.5:1.5; 0.0184g of azobisisobutyronitrile is added in step (2); the weight-average molecular weight of the obtained water-soluble nonionic polymer viscosity reducer is 1.307× 10 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com