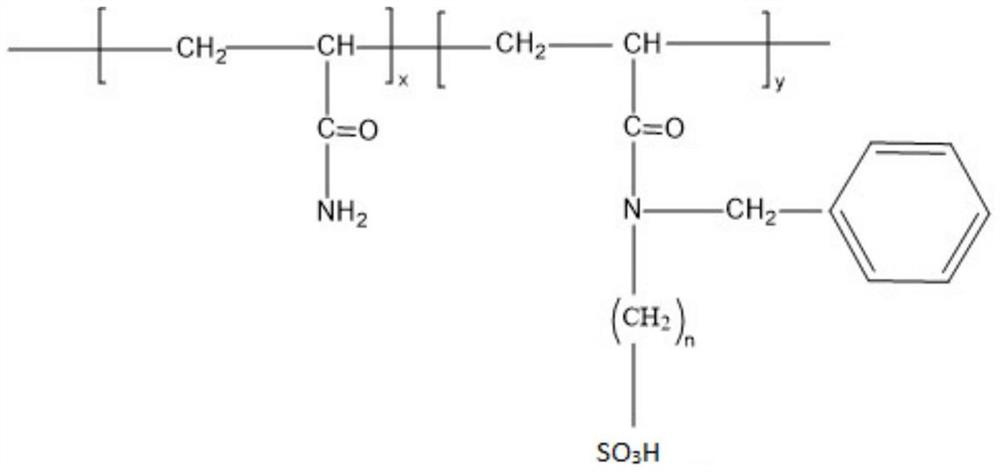

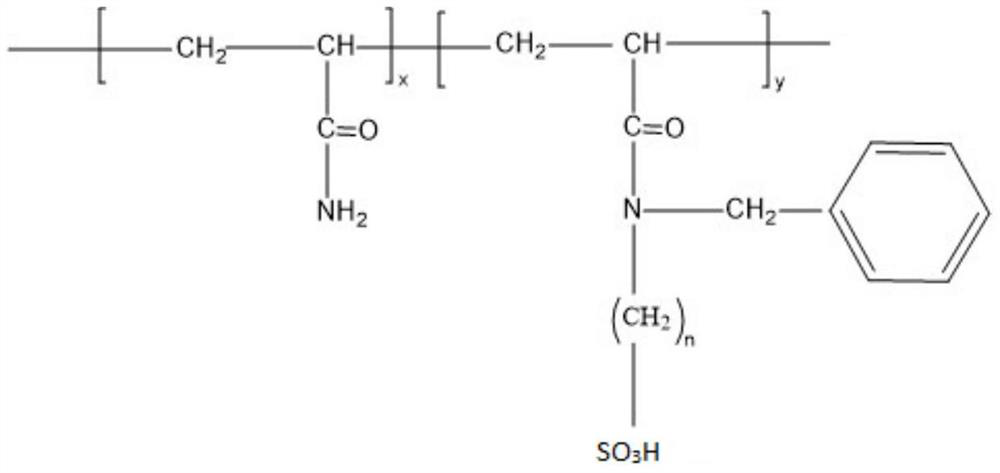

Temperature-resistant and salt-resistant fracturing fluid thickening agent and preparation method thereof

A fracturing fluid thickener and salt type technology, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low polymer molecular weight, poor temperature and salt resistance, etc., and achieve fast reaction speed, Avoid the effect of steric hindrance between groups, and the reaction process is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a temperature-resistant and salt-resistant fracturing fluid thickener, comprising the following steps:

[0038] Step 1, α-olefin amine and SO 3 Carry out the sulfonation reaction, cool the brine to control the sulfonation temperature to 5-10°C, heat the mixed liquid after sulfonation to 50-60°C to separate layers, take the lower milky liquid, and dry under vacuum for 12 hours to obtain the alkyl sulfonate amine;

[0039] Step 2. Reflux the above-prepared alkylamine sulfonate and benzaldehyde at 70°C for 16 hours, lower the reaction temperature to 5°C-10°C, and perform rotary distillation under reduced pressure. The residue after distillation is benzamide alkylsulfonate acid;

[0040] Step 3. Lower the temperature of benzamide alkylsulfonic acid to 0-5°C, and react with acryloyl chloride in the presence of triethylamine for 4-6 hours to obtain a temperature-resistant and salt-resistant functional monomer N-benzyl-N- Acryla...

preparation Embodiment 1

[0069] Add 100g of α-butenylamine and 200ml of dichloromethane into a four-necked flask, cool it to 5°C with an ice-water bath, and slowly introduce 138g of SO 3 Carry out the sulfonation reaction, control the feed rate so that the reaction temperature is maintained below 10°C, after 6 hours of reaction, heat the sulfonated mixture to 50°C and continue the reaction for 2 hours, take off the milky liquid in the lower layer by layering, and dry under vacuum for 12 hours , to obtain butylamine sulfonate;

[0070] 50 g of butylamine sulfonate prepared in the above steps and 35 g of benzaldehyde were refluxed at 70°C for 16 hours, the reaction temperature was lowered to 10°C, and rotary distillation was performed under reduced pressure. The residue after distillation was benzamide butylsulfonic acid;

[0071] Add 50g of benzamide butyl sulfonic acid and 100ml of dichloromethane into a four-neck flask, lower the temperature to 2°C, add 1g of triethylamine, then start to drop 20.2g o...

preparation Embodiment 2

[0073] Add 100g of α-butenylamine and 200ml of acetone into a four-necked flask, cool it to 8°C with an ice-water bath, and slowly introduce 122g of SO 3 Carry out the sulfonation reaction, control the feed rate so that the reaction temperature is maintained below 10°C, after 8 hours of reaction, heat the sulfonated mixture to 60°C and continue the reaction for 2 hours, take off the milky liquid in the lower layer by layering, and dry under vacuum for 12 hours , to obtain butylamine sulfonate;

[0074] 50 g of butylamine sulfonate prepared in the above steps and 35 g of benzaldehyde were refluxed at 70°C for 16 hours, the reaction temperature was lowered to 10°C, and rotary distillation was performed under reduced pressure. The residue after distillation was benzamide butylsulfonic acid;

[0075] Add 50g of benzamide butylsulfonic acid and 100ml of acetone into a four-necked flask, lower the temperature to 3°C, add 2g of triethylamine, then start to drop 22g of acryloyl chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com