Oil well cement dispersing agent and preparation method thereof

An initiator and selected technology, applied in the field of oilfield cementing, can solve the problems of difficulty in meeting the requirements of special cement slurry system, incompatibility of new admixtures, low temperature resistance, etc., achieving good pumpability, improving Flow properties, the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

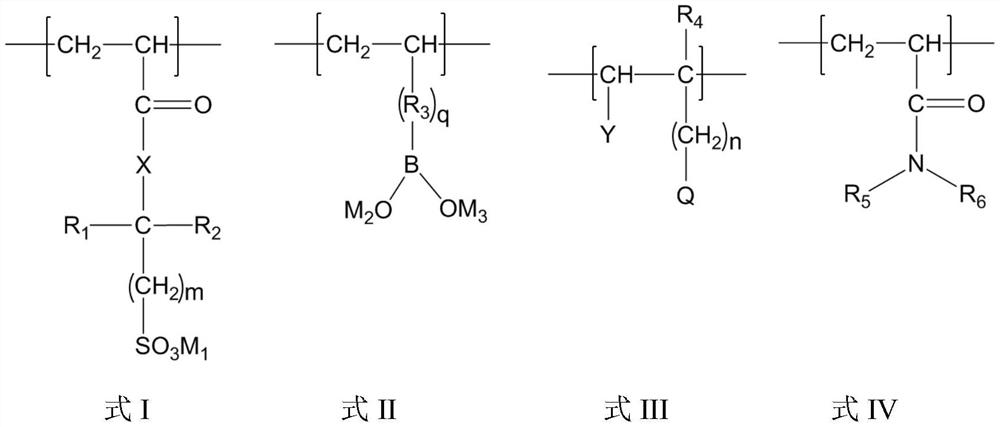

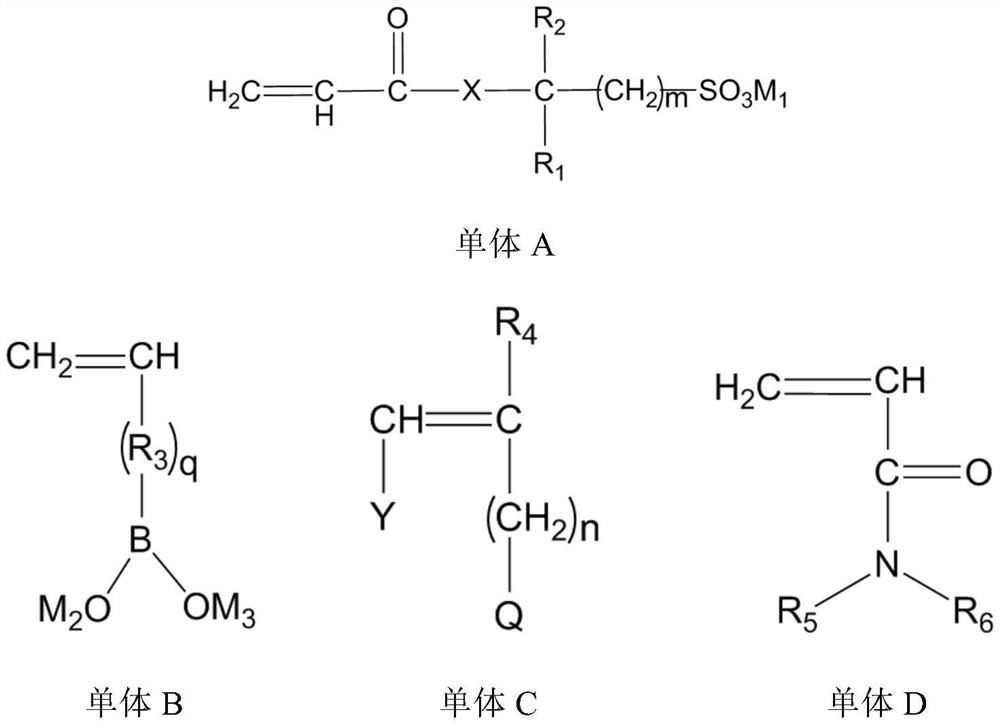

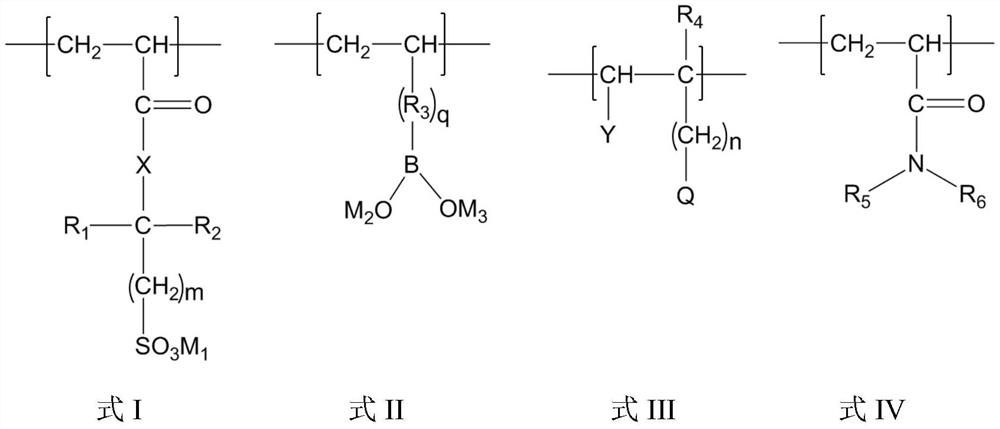

Method used

Image

Examples

Embodiment 1

[0085] Weigh 1035g (5mol) of 2-acrylamide-2-methylpropanesulfonic acid, 444g (3mol) of 4-vinylbenzeneboronic acid, 144g (2mol) of acrylic acid and 2560g of deionized water into beaker A and mix well , to obtain a monomer mixture. Weigh 21g (0.2mol) of 3-mercaptopropionic acid, 9g (0.05mol) of ascorbic acid and 640g of deionized water into beaker B, and mix well to obtain the first mixture. Next, weigh 6g of hydrogen peroxide (concentration: 30%) (0.05mol) and 260g of deionized water into a four-neck flask equipped with a thermometer and a stirrer, heat to 65°C, keep the temperature constant and keep stirring. Subsequently, the monomer mixture and the first mixture were pumped into the four-necked flask at a constant speed by two flow pumps at the same time. After the addition was completed, the reaction was maintained at 65°C for 1 hour to obtain a boron-containing polymer 1 with a solid content of 32%. Determined by GPC to be 9.4×10 3 .

Embodiment 2

[0087] Weigh 145g (0.7mol) of 2-acrylamide-2-methylpropanesulfonic acid, 45g (0.3mol) of 4-vinylphenylboronic acid and 300g of deionized water into beaker A, and mix well to obtain a monomer mixture. Weigh 2.1g (0.02mol) of 3-mercaptopropionic acid, 0.9g (0.005mol) of ascorbic acid and 64g of deionized water into beaker B, and mix well to obtain the first mixture. Next, weigh 0.6g of hydrogen peroxide (concentration: 30%) (0.005mol) and 27g of deionized water into a four-neck flask equipped with a thermometer and a stirrer, heat to 65°C, keep the temperature constant and continue to stir. Subsequently, the first solution and the first mixture were pumped into the four-necked flask by two flow pumps simultaneously. After the addition was completed, the reaction was maintained at 65°C for 1 hour to obtain a boron-containing polymer 2 with a solid content of 33%. GPC determined to be 1.16×10 4 .

Embodiment 3

[0089] Weigh 62g (0.3mol) 2-acrylamide-2-methylpropanesulfonic acid, 74g (0.5mol) 4-vinylbenzeneboronic acid, 20g (0.2mol) N,N-dimethylacrylamide and 246g deionized Add water into beaker A and mix well to obtain a monomer mixture. Weigh 2.1 (0.02 mol) g 3-mercaptopropionic acid, 0.9 g (0.005 mol) g ascorbic acid (Vc) and 64 g deionized water into beaker B, and mix well to obtain the first mixture. Weigh 0.6g of hydrogen peroxide (concentration: 30%) (0.005mol) and 27g of deionized water into a four-neck flask equipped with a thermometer and a stirrer, heat to 65°C, keep the temperature constant and keep stirring. Subsequently, the monomer mixture and the first mixture were simultaneously pumped into the four-necked flask by two flow pumps. After the addition was completed, the reaction was maintained at 65°C for 1 hour to obtain a boron-containing polymer 3 with a solid content of 32%. GPC determined to be 8.3×10 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com