Monomer-containing solvent refining system and process

A solvent refining and monomer technology, applied in sustainable manufacturing/processing, chemical industry, carboxylate preparation, etc., can solve the problem of low mass transfer and heat transfer efficiency, high content of polymerization inhibitor, and uneven distribution of gas-liquid two-phase To achieve the effect of strengthening gas-liquid mass transfer and heat transfer, reducing the degree of wall flow, and enhancing the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

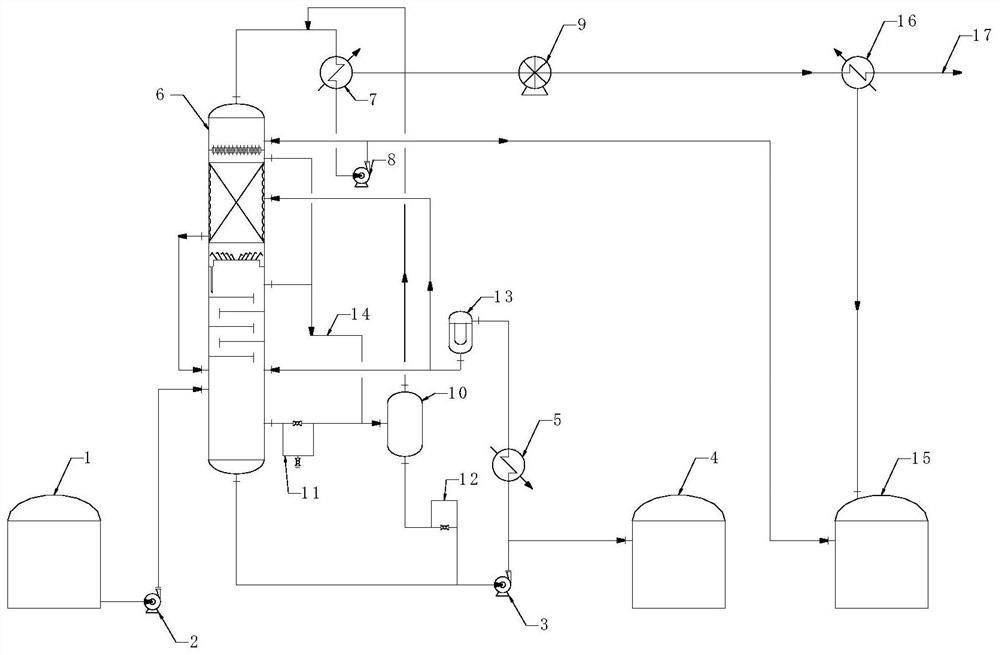

[0042] A monomer-containing solvent refining system, comprising a crude solvent tank 1, a weight-removing tower 6, a flash tank 10, and a reboiler 5; the crude solvent tank 1 outlet pipeline is connected to the weight-removing tower 6 stills, the weight-removing tower 6 stills And each section in the tower is connected to the flash tank 10 through the overflow pipeline, and a branch after the liquid phase outlet pipeline of the flash tank 10 and the outlet pipeline at the bottom of the weight-removing tower 6 is brought together is connected with the reboiler 5, and the other is connected to the reboiler 5. The branch is connected with the waste liquid tank 4; the outlet pipeline of the reboiler 5 goes to the weight-removing tower 6; Condenser 7 is connected; the liquid phase outlet pipeline of weight-removing tower condenser 7 and the liquid-phase outlet pipeline of weight-removing tower 6 tower top are brought together and are connected with recovery solvent tank 15, and the ...

Embodiment 2

[0047] The monomer-containing solvent refining system used in this example is based on the system in Example 1, and a corrugated buckle tube is added between the packing and the wall of the weight-removing tower. The outer diameter of the buckle tube is 40mm, and the buckle tube is The center distance is 80mm. In addition, the discharge pipe of the reboiler 5 is divided, and one branch pipe goes to the 6 tower stills of the weight-removing tower, and the other branch pipe goes to the buckle pipe in the packing, and the outlet end pipeline of the buckle pipe is in phase with the 6 tower stills of the weight-removing tower. connect.

[0048] A monomer-containing solvent refining process, comprising the following processes:

[0049] The crude solvent from the crude solvent tank 1 is sent to the weight-removing tower 6 with a flow of 5000kg / h, and the light component at the top of the tower is condensed by the weight-removing tower condenser 7 and enters the recovery solvent tank...

Embodiment 3

[0052] The monomer-containing solvent refining system used in this example is based on the system in Example 2, and a corrugated buckle tube of the same specification is added at the position directly opposite to the corrugated buckle tube; in addition, the outlet of the reboiler 5 A branch is added to the material pipe, which leads to the additional buckle pipe, and the outlet end pipeline of the buckle pipe is also connected to the 6 column kettle of the weight-removing tower.

[0053] A monomer-containing solvent refining process, comprising the following processes:

[0054] The crude solvent from the crude solvent tank 1 is sent to the weight-removing tower 6 with the flow rate of the tower design feed load upper limit 10000kg / h, and the light component at the top of the tower is condensed by the weight-removing tower condenser 7 with a flow rate of 9848kg / h Enter the recovery solvent tank 15 . A part of the heavy components of the tower kettle is transported to the waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com