Electro-catalysis application of horseradish peroxidase sensor constructed by black phosphorus-based composite material

A technology of composite materials and nanocomposites, which is applied in the field of preparation of electrochemical sensors, can solve problems such as poor stability, and achieve the effects of improving conductivity, high surface activity, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the present invention, the preparation method of the thin-layer BPNs-SWCNTs nanocomposite material and its modified electrode to obtain the preparation method of BPNs-SWCNTs / CILE preferably include the following steps:

[0028] First, thin-layer BPNs-SWCNTs nanocomposites were prepared by liquid phase exfoliation method and physical mixing method. Then the CILE and composite nanomaterials were put into the glove box, the glove box was evacuated, and then N 2 , and then a thin layer of BPNs-SWCNTs was drop-coated on the surface of CILE, and after natural drying, the BPNs-SWCNTs / CILE modified electrode was obtained.

[0029] In the present invention, the BPNs dispersion liquid is a thin-layer BPNs dispersion liquid; in the present invention, the BPNPs are preferably pretreated, and in the present invention, the pretreatment preferably includes: ultrasonicating the BPNPs solution, and the ultrasonic time It is preferably 8-12 h, more preferably 12 h, centrifuged at 100...

Embodiment 1

[0036] First, the BPNPs and NMP were mixed in an ice bath and sonicated for 12 hours, and then centrifuged at 10,000 rmp and 12,000 rmp for 20 minutes to prepare a thin-layer BPNs dispersion; the BPNs dispersion was mixed with SWCNTs by a physical mixing method and ultrasonicated for 4 hours to obtain a thin layer. BPNs-SWCNTs nanocomposite; polish the surface of the CILE electrode, put it into the glove box together with the composite, evacuated the glove box, and then passed N 2 ; First drop-coating BPNs-SWCNTs nanocomposite on the surface of CILE, and after natural drying, the BPNs-SWCNTs / CILE modified electrode was obtained. Other modified electrodes SWCNTs / CILE and BPNs / CILE were prepared by coating method, and BPNs / CILE and BPNs-SWCNTs / CILE electrodes did not need to be stored in a refrigerator at 4 °C.

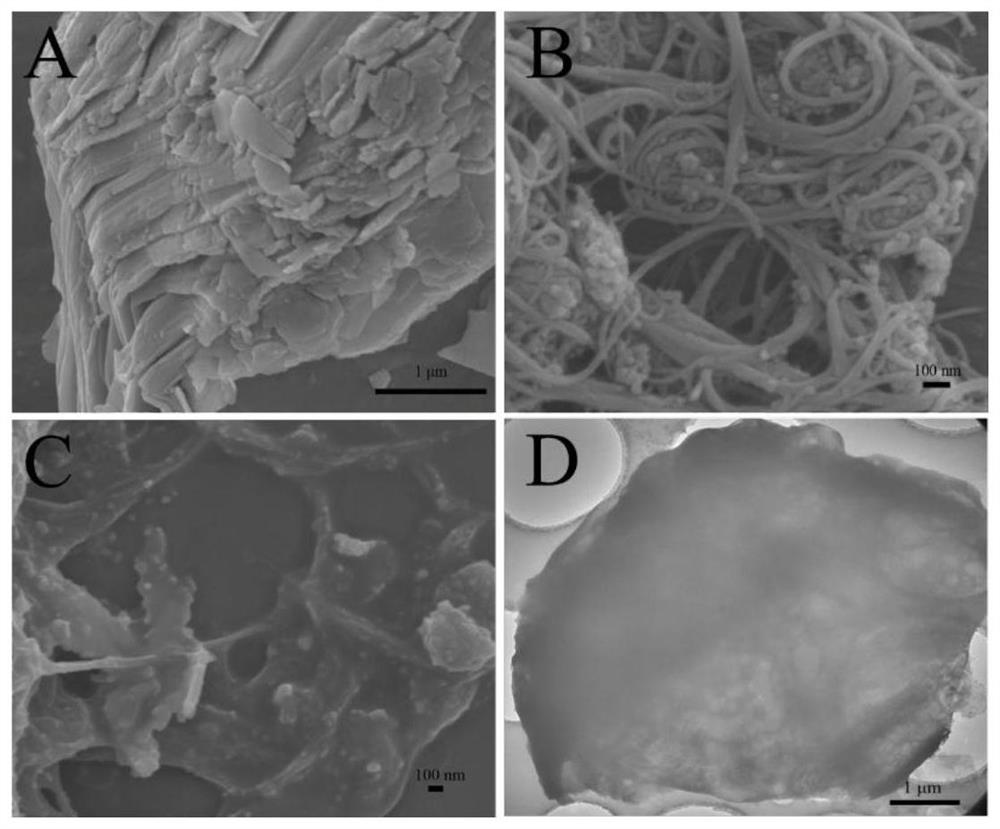

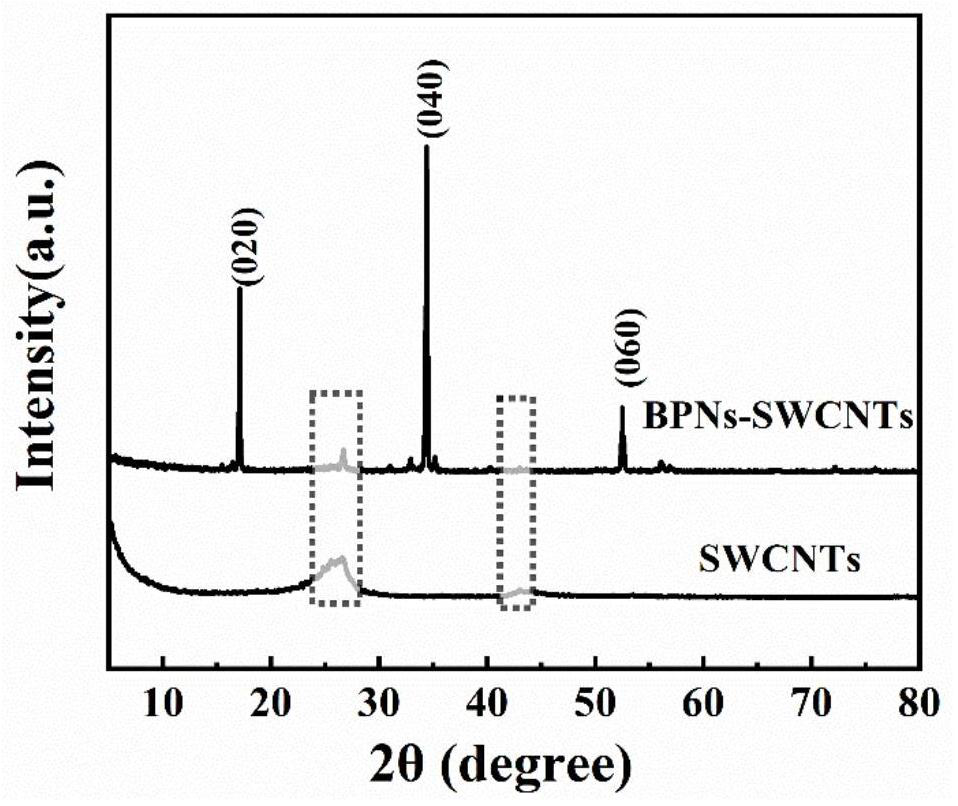

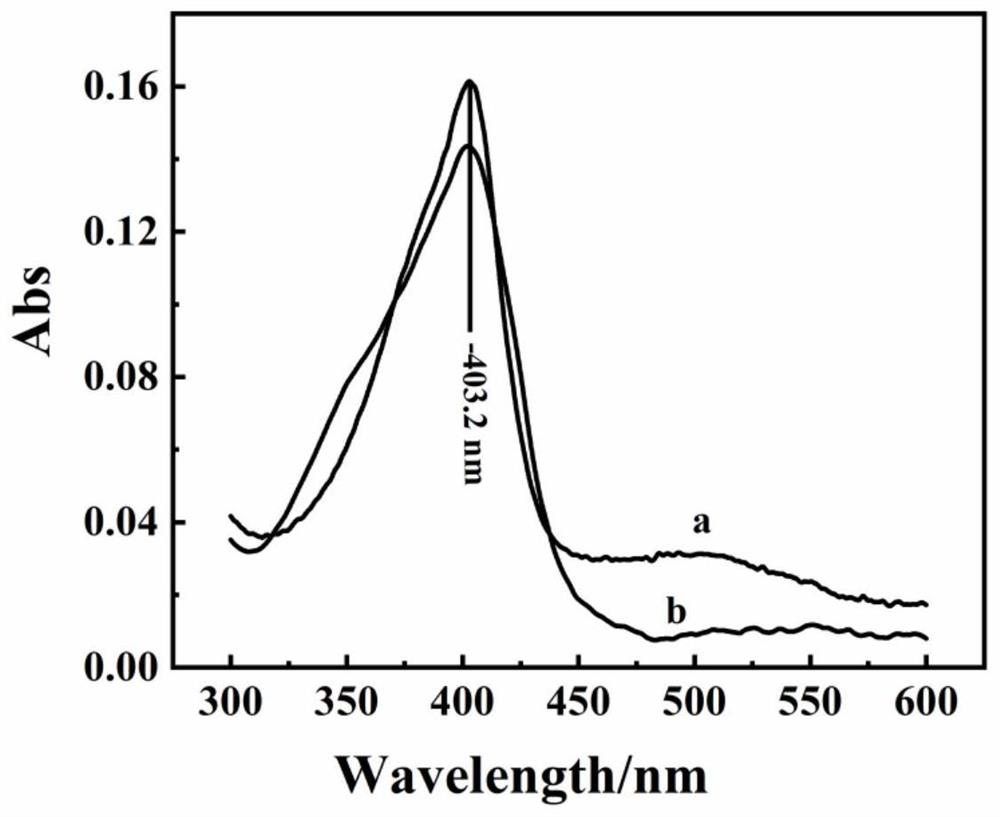

[0037] figure 1 SEM and TEM images of different materials, among which, figure 1 A is the scanning electron microscope photo of the multilayer BPNPs with a scale of 1...

Embodiment 2

[0047] The BPNs-SWCNTs / CILE modified electrode obtained in Example 1; after drying at room temperature, HRP was dropped on the BPNs-SWCNTs / CILE electrode to obtain the HRP / BPNs-SWCNTs / CILE modified electrode; then Nafion was added dropwise on the above electrode, After natural drying, the prepared modified electrode Nafion / HRP / BPNs-SWCNTs / CILE. Other modified electrodes Nafion / HRP / CILE, Nafion / HRP / SWCNTs / CILE and Nafion / HRP / BPNs / CILE were prepared by the same method. All electrodes do not need to be stored in a refrigerator at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com