Acetylene gas purification device in 1.4 butanediol production process and process thereof

A production process and purification device technology, applied in the field of acetylene gas purification devices, can solve the problems of high processing cost, pollution, destruction of copper-bismuth catalyst, etc., and achieve the effects of reducing cost expenditure, reducing floor space and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

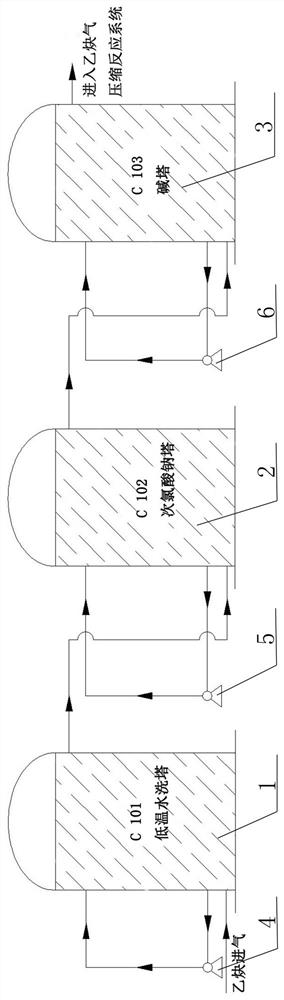

[0021] like figure 1 Shown, a kind of acetylene gas purification device in a 1.4 butanediol production process, comprising a low temperature water washing tower 1 connected by a pipeline with an inlet pipe of acetylene gas, a sodium hypochlorite tower 2 connected by a pipeline with the outlet of the low temperature water washing tower 1, and The air outlet of the sodium hypochlorite tower 2 is connected with the alkali tower 3 by the pipeline, the air outlet of the alkali tower 3 is connected with the compression reaction system of the acetylene gas, and the liquid inlet and the waste liquid discharge port of the sodium hypochlorite tower 2 are respectively connected with the liquid supply mechanism and the waste liquid through the pipeline. Liquid collection mechanism connection. The liquid supply mechanism includes a preparation tank for disposing sodium hypochlorite, a placement tank for containing sodium hypochlorite, and the placement tank is connected with the liquid inl...

Embodiment 2

[0025] A process for purifying acetylene gas in 1.4 butanediol production process, comprising the following steps, step 1: crude acetylene gas is supplied into an acetylene gas purification unit from an acetylene gas tank, and the crude acetylene gas is first pressurized by an acetylene inlet compressor, Then enter the low temperature washing tower 1 through the acetylene inlet pipe, in the low temperature washing tower 1, the crude acetylene gas is in countercurrent contact with the process water in the low temperature washing tower 1; The cooler uses chilled water to cool the low-temperature ethylene glycol of the cooler to maintain the low-temperature ethylene glycol temperature at 8±2°C, so that the temperature of the water in the low-temperature washing tower 1 is relatively low.

[0026] Step 2: The acetylene gas enters the sodium hypochlorite column 2 after being washed by the low-temperature water washing tower in step 1. In the sodium hypochlorite column 2, the acetyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com