Coal-fired power plant coal dust pipeline coal dust concentration leveling device and method

A technology for pulverized coal pipelines and coal-fired power plants, which is applied to combustion methods, combustion control, and combustion equipment, etc., can solve the problems of obstruction of the flow of pulverized coal, the actual effect of pulverized coal can not reach expectations, and the amount of pulverized air is limited. Tube resistance, efficient operation and stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

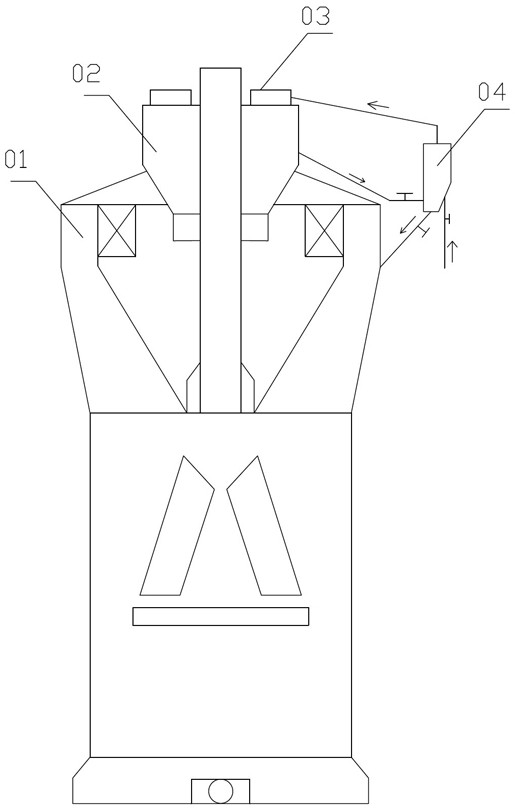

[0024] combined with figure 1 to the attached figure 2 , a pulverized coal concentration leveling device for pulverized coal pipelines in coal-fired power plants, on each of the pulverized air main pipelines on the coal mill from the separator 01 up to the mixer 02 and then to each main powder pipe 03, at least one pulverized air pipeline is arranged in parallel Bypass pipe; the bypass pipe is equipped with an ejector 04, through the suction effect of the ejector 04 to achieve the balance of the powder concentration between the pipes.

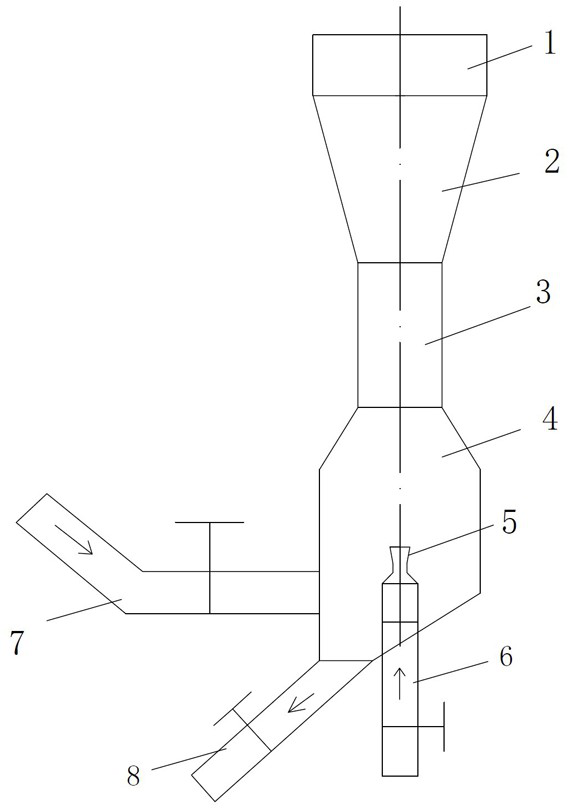

[0025] Preferably, the ejector 04 includes an outflow pipe 1, a diffusion chamber 2, a mixing chamber 3, a receiving chamber 4, a jet nozzle 5, an inlet pipe 6, a suction pipe 7 and a return pipe 8; the inlet pipe The inlet end of 6 is connected with a compressed air source, the outlet end is connected with the jet nozzle 5, the jet nozzle 5 extends into the interior of the receiving chamber 4, and the receiving chamber 4 is sequentially conn...

specific Embodiment 2

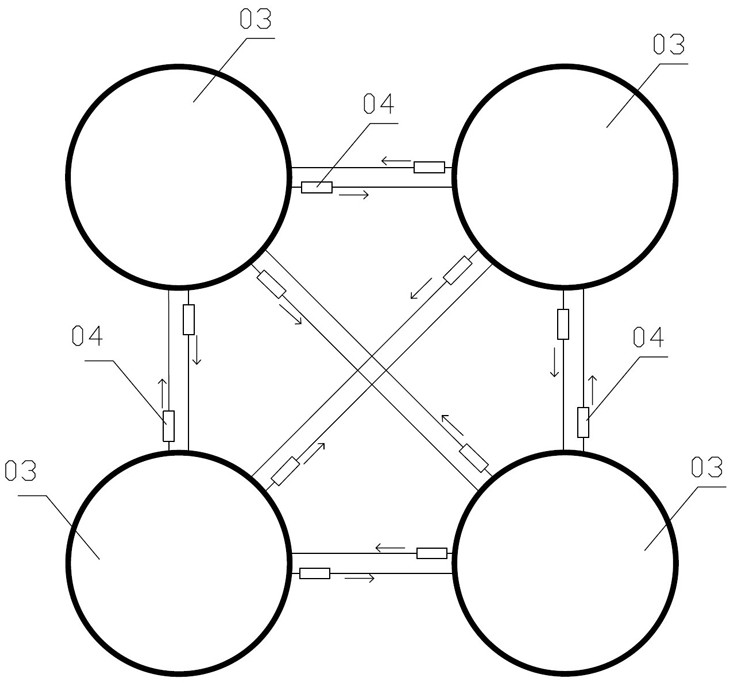

[0028] combined with figure 2 with attached image 3, a pulverized coal concentration leveling device for pulverized coal pipelines in coal-fired power plants, which directly connects the main powder pipes 03 above each mixer 02 through two bypass pipes with opposite flow directions; the diameter of the bypass pipes is obvious It is smaller than the diameter of the main pipeline; an ejector 04 is installed on the bypass pipeline, and the suction effect of the ejector 04 is used to achieve the balance of the powder concentration among the pipelines.

[0029] Preferably, the ejector 04 includes an outflow pipe 1, a diffusion chamber 2, a mixing chamber 3, a receiving chamber 4, a jet nozzle 5, an inlet pipe 6, a suction pipe 7 and a return pipe 8; the inlet pipe The inlet end of 6 is connected with a compressed air source, the outlet end is connected with the jet nozzle 5, the jet nozzle 5 extends into the interior of the receiving chamber 4, and the receiving chamber 4 is seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com