Hydraulic control system with effect of closed loop detection on actual situation of sealing of plunger type sludge pump

A hydraulic control system and closed-loop detection technology, which is applied in the field of sludge pumping hydraulic pressure, can solve problems such as extensive oil replenishment process, out-of-synchronization of two cylinders, and influence on normal operation of equipment, achieving efficient and reliable operation and timely feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

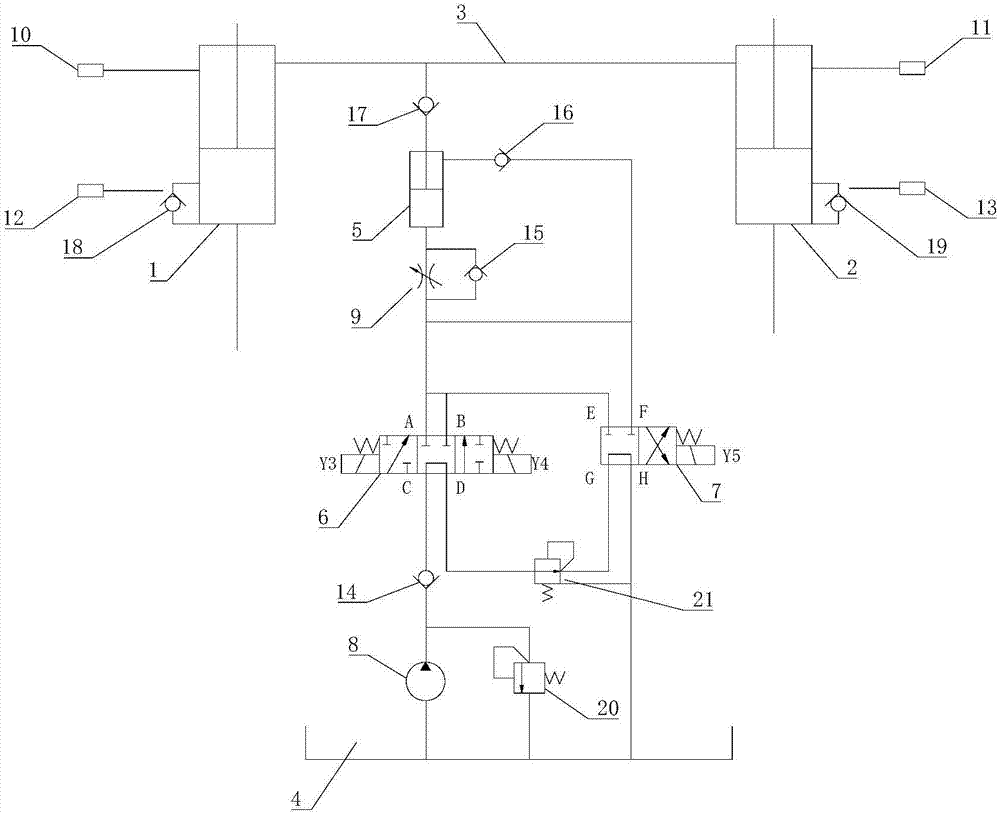

[0016] Such as figure 1 As shown, a hydraulic control system with closed-loop detection of the seal of the plunger type sludge pump includes the first master cylinder 1 and the second master cylinder 2, the rod cavity of the first master cylinder 1 and the second master cylinder 2 The rod cavity is connected in series to form a connecting cavity 3; it also includes an oil replenishment device and a monitoring control device; the oil replenishment device includes an oil replenishment tank 4, a servo hydraulic cylinder 5, an oil inlet control valve 6, an oil return control valve 7, and a hydraulic pump 8 , flow control valve 9; one end of the servo hydraulic cylinder 5 is connected to the communication chamber 3, and the other end is sequentially connected to the flow control valve 9, the oil inlet control valve 6, the hydraulic pump 8, and the oil replenishment tank 4 to form an oil replenishment circuit; The oil return control valve 7 is respectively connected to the servo hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com