Preparation method and application of fluorescent composite glass film

A composite glass and thin film technology, applied in the field of laser lighting, can solve the problems of low heat dissipation of fluorescent conversion materials and limit the application of fluorescent conversion materials, etc., and achieve the goals of improving laser saturation threshold and luminous flux, increasing scattering effect, good luminous performance and heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A composite fluorescent glass material with high heat dissipation applied to laser lighting and a preparation method thereof, wherein the dominant wavelength range of a blue-light laser diode is between 460 and 480 nm.

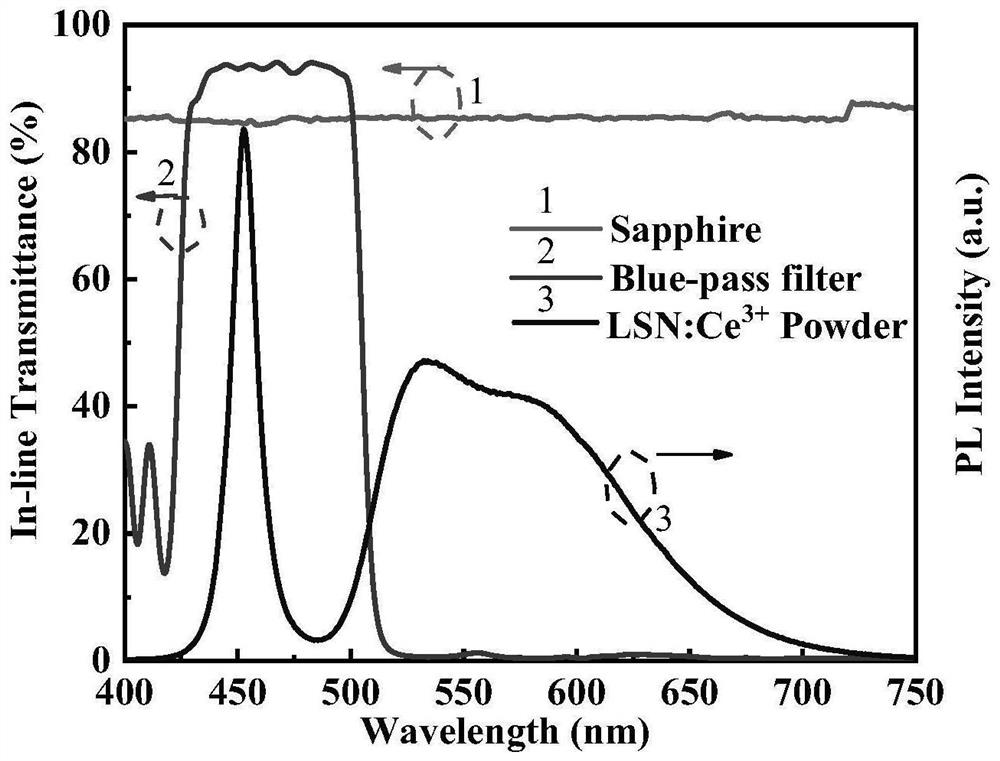

[0035] Among them, the blue light transmission film can reflect yellow light with a wavelength of 520-800 nm, and transmit blue light with a wavelength of ≤ 510 nm, such as figure 2 shown.

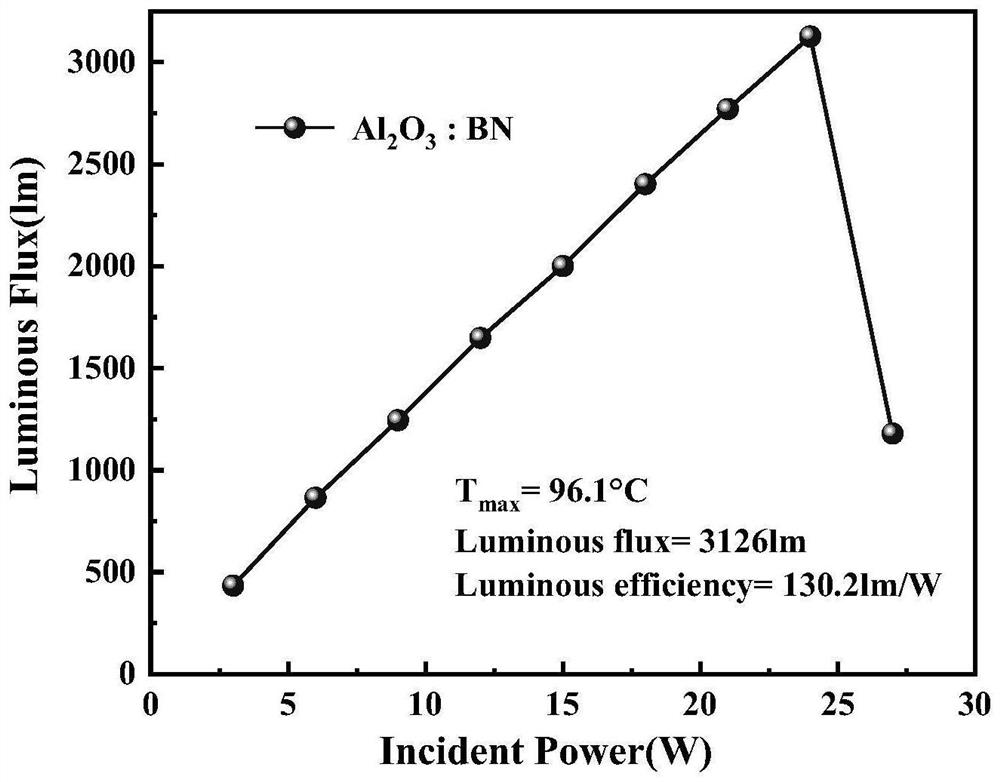

[0036] The composite fluorescent glass film is composed of 30% La 3 Si 6 N 11 :Ce 3+ Phosphor, 20%K 2 O-Na 2 O-Al 2 O 3 -SiO 2 Glass powder, 25% Al 2 O 3 It is mixed with 25% BN. After mixing evenly, the organic slurry is added and mixed again to obtain a mixed slurry. The mixed slurry is coated on a sapphire substrate with a thickness of 50 μm, and placed on a constant temperature table of 100-110 °C for 10 minutes. After molding It is then placed in a muffle furnace and burned to 800° C. at 5° C. / min, and then naturally lowered to room temperature afte...

Embodiment 2

[0041] A composite fluorescent glass material with high heat dissipation applied to laser lighting and a preparation method thereof, wherein the dominant wavelength range of a blue-light laser diode is between 460 and 480 nm.

[0042] The composite fluorescent glass film is composed of 30% La 3 Si 6 N 11 :Ce 3+ Phosphor, 20%K 2 O-Na 2 O-Al 2 O 3 -SiO 2 Glass powder, 25% Al 2 O 3It is mixed with 25% AlN. After mixing evenly, the organic slurry is added and mixed again to obtain a mixed slurry. The mixed slurry is coated on the sapphire substrate with a thickness of 50 μm, and placed on a constant temperature table of 100 ~ 110 ℃ to cure for 10 minutes. After molding It is then placed in a muffle furnace and burned to 800° C. at 5° C. / min, and then naturally lowered to room temperature after being kept for 10 minutes to obtain a composite fluorescent glass film layer.

[0043] The luminescence performance data obtained by exciting the composite fluorescent glass thin f...

Embodiment 3

[0047] A composite fluorescent glass material with high heat dissipation applied to laser lighting and a preparation method thereof, wherein the dominant wavelength range of a blue-light laser diode is between 460 and 480 nm.

[0048] The composite fluorescent glass film is composed of 30% La 3 Si 6 N 11 :Ce 3+ Phosphor, 20%K 2 O-Na 2 O-Al 2 O 3 -SiO 2 Glass powder, 25% AlN and 25% BN are mixed. After mixing evenly, add organic slurry and mix again to obtain a mixed slurry. The mixed slurry is coated on a sapphire substrate with a thickness of 50 μm, and placed at a constant temperature of 100-110 °C The table is cured for 10 minutes, and then placed in a muffle furnace and fired to 800° C. at 5° C. / min. After being kept for 10 minutes, it is naturally lowered to room temperature to obtain a composite fluorescent glass film layer.

[0049] The luminescence performance data obtained by exciting the composite fluorescent glass thin film layer with different laser power b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com