Titanium-based composite material with multi-scale microstructure and preparation method of titanium-based composite material

A titanium-based composite material and microstructure technology, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve problems such as pollution, complex powder spreading process, and complex process process, so as to meet the needs of use and improve stability. Sexual, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A second aspect of the present invention provides a preparation method of a titanium-based composite material with a multi-level scale microstructure, the preparation method comprising the steps of:

[0047] (1) Laser 3D printing the first spherical titanium-based powder to obtain a titanium-based frame;

[0048] (2) fully mixing the second spherical titanium-based powder with the ceramic powder, and leaving it to stand to obtain the titanium-based mixed powder;

[0049] (3) filling the titanium-based mixed powder into the titanium-based frame to obtain a powder-filled frame;

[0050] (4) The powder-filled frame is sintered and cooled by vacuum hot pressing to obtain a titanium-based composite material with a multi-scale microstructure filled with titanium-based reinforcing materials inside the titanium-based frame.

[0051] In the present invention, the first spherical titanium-based powder is prepared by laser 3D printing to prepare the titanium-based frame, and then...

Embodiment 1

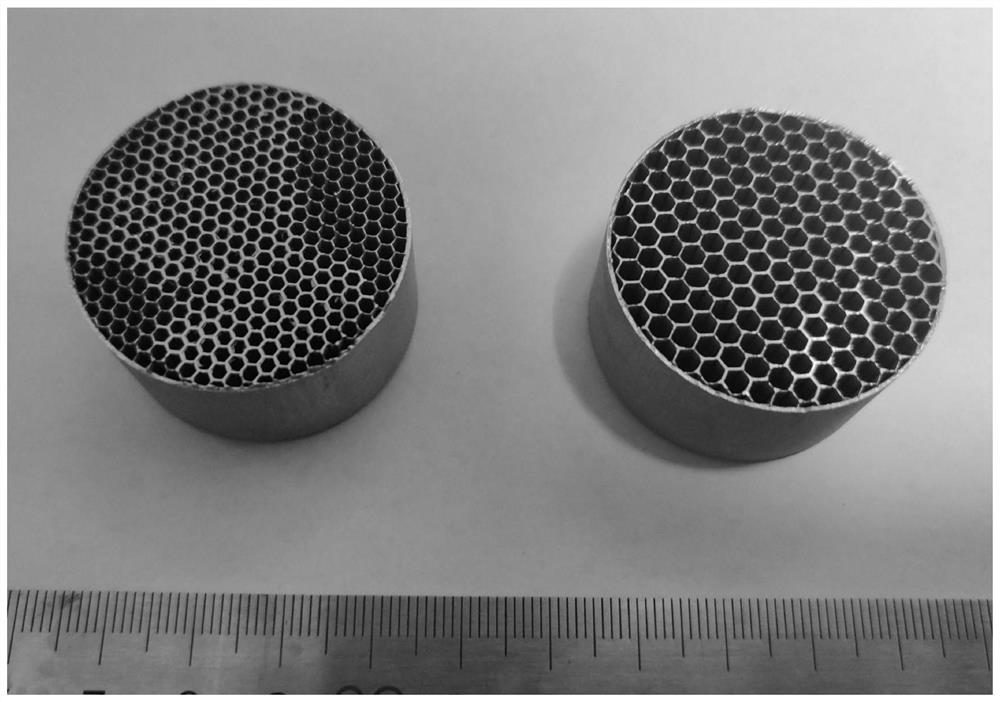

[0074] (1) laser 3D printing TA15 (first spherical titanium-based powder) with a particle size of 30-53 μm to obtain a titanium-based frame (honeycomb TA15 titanium alloy frame);

[0075] (2) TA15 (second spherical titanium-based powder) with a particle size of 75-150 μm and 2wt% TiB with a particle size of 1-8 μm 2 (Ceramic powder) Carry out ball milling treatment under argon atmosphere for 5h, and continue to stand in the ball mill tank for 6h in argon atmosphere to obtain titanium-based mixed powder; wherein, the mass fraction of TA15 titanium alloy powder is 98wt%, TiB 2 The mass fraction is 2wt%, the rotating speed of ball milling is 200r / min, and the ratio of ball to material is 4:1;

[0076] (3) filling the titanium-based mixed powder into the titanium-based frame to obtain a powder-filled frame;

[0077] (4) Set the powder-filled frame at 1200℃, 22MPa and vacuum degree ≥1×10 -2 Vacuum hot-pressing sintering was carried out for 1.5 h in the environment of Pa to obtain...

Embodiment 2

[0080] (1) Laser 3D printing TA15 titanium alloy powder (first spherical titanium-based powder) with a particle size of 30-53 μm to obtain a titanium-based frame (honeycomb TA15 titanium alloy frame);

[0081] (2) TA15 titanium alloy powder (second spherical titanium-based powder) with a particle size of 75 to 150 μm and TiB with a particle size of 1 to 8 μm 2 (Ceramic powder) Perform ball milling for 4 hours in an argon atmosphere, and continue to stand in a ball mill for 6 hours in an argon atmosphere to obtain a titanium-based mixed powder; wherein, the mass fraction of the TA15 titanium alloy powder is 99 wt%, and the TiB 2 The mass fraction is 1wt%, the speed of ball milling is 180r / min, and the ratio of ball to material is 3:1;

[0082] (3) filling the titanium-based mixed powder into the titanium-based frame to obtain a powder-filled frame;

[0083] (4) Set the powder-filled frame at 1100℃, 20MPa and vacuum degree ≥1×10 -2 Vacuum hot-pressing sintering was carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com