Environment-friendly fluoride-free fabric waterproof moisture-permeable agent as well as preparation method and application thereof

A waterproof and moisture-permeable agent, an environmentally friendly technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of high bioaccumulation, hard fabric feel, difficult to degrade, etc., and achieve simple production process, good air permeability, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the aforementioned environmentally friendly fluorine-free fabric waterproof and moisture-permeable agent, comprising the following steps:

[0046] The monomer, the crosslinking agent and the initiator are mixed with the solvent A and the solvent B, added to the initiator dissolved by the solvent A and the solvent B, and the temperature is raised to react. After the reaction is completed The temperature is lowered, the regulator is added for neutralization reaction, the diluent is added to dilute and disperse to obtain an emulsion system, and the fluorine-free fabric waterproof and moisture-permeable agent is prepared.

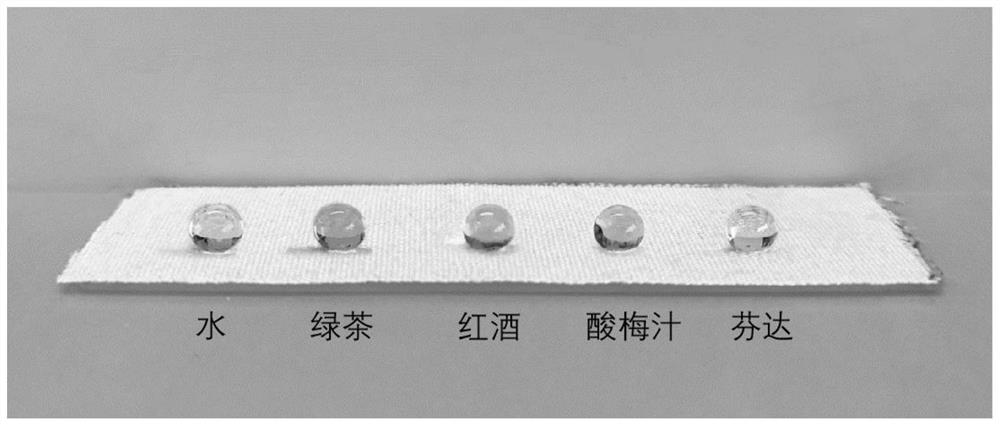

[0047] The application of the fluorine-free fabric waterproof and moisture-permeable agent on the fabric, the fabric includes sportswear, medical protective clothing or ordinary clothes, shoes and hats.

[0048] A waterproof and moisture-permeable fabric, the waterproof and moisture-permeable fabric is obtained by finishing the ...

Embodiment 1

[0052] The fluorine-free waterproof and moisture-permeable fabric provided in the embodiment of the present invention has the following components, proportions, and steps of preparation and application:

[0053] (1) Synthetic fluorine-free fabric waterproof and moisture-permeable agent

[0054] Weigh 3.9g solvent isopropanol, propylene glycol butyl ether and 0.012g 2,2'-azobisisobutyronitrile respectively and add them to the three-necked flask, heat up to 90°C with an oil bath, and then add 4.4g ten Octene, 0.4g N-methylol acrylamide, 1.6g octadecyl methacrylate, 1.2g butyl methacrylate, 0.16g acrylic acid, 0.24g vinyl terminated polydimethyl methacrylate with molecular weight of 2000 Siloxane, 0.056g 2,2'-azobisisobutyronitrile, 2.1g isopropanol, 2.1g propylene glycol butyl ether were ultrasonically mixed, titrated into a three-necked flask, titrated for 30min, and then added 0.012g 2,2 '-Azobisisobutyronitrile was heated to 100°C, kept for 10h, cooled to room temperature af...

Embodiment 2

[0060] The fluorine-free waterproof and moisture-permeable fabric provided in the embodiment of the present invention has the following components, proportions, preparation and application steps:

[0061] (1) Synthetic fluorine-free fabric waterproof and moisture-permeable agent

[0062] Weigh 3.9g of solvent isopropanol, propylene glycol butyl ether (1:1), 0.012g of 2,2'-azobisisobutyronitrile were added to the three-necked flask, heated to 90°C with an oil bath, and then added to the three-necked flask. 4.4 g octadecene, 0.4 g N-methylol acrylamide, 1.36 g octadecyl methacrylate, 1.36 g butyl methacrylate, 0.24 g acrylic acid, 0.24 g vinyl terminated with a molecular weight of 1250 Polydimethylsiloxane, 0.056g 2,2'-azobisisobutyronitrile, 2.1g isopropanol, 2.1g propylene glycol butyl ether were ultrasonically mixed, titrated into a three-necked flask, titrated for 30min, and then added 0.012 g 2,2'-azobisisobutyronitrile, heated to 100°C, kept for 10h, cooled to room temper...

PUM

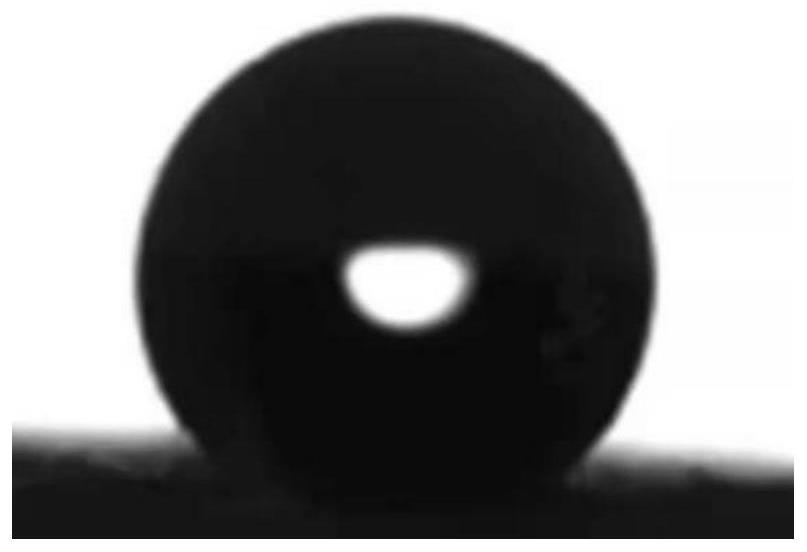

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com