Grinding fluid for processing silicon carbide wafer and preparation method of grinding fluid

A technology of wafer processing and silicon carbide, which is applied in chemical instruments and methods, other chemical processes, semiconductor/solid-state device manufacturing, etc., can solve the problems of easily scratched silicon carbide wafers, wafer scrapping, etc., and achieve particle size concentration and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

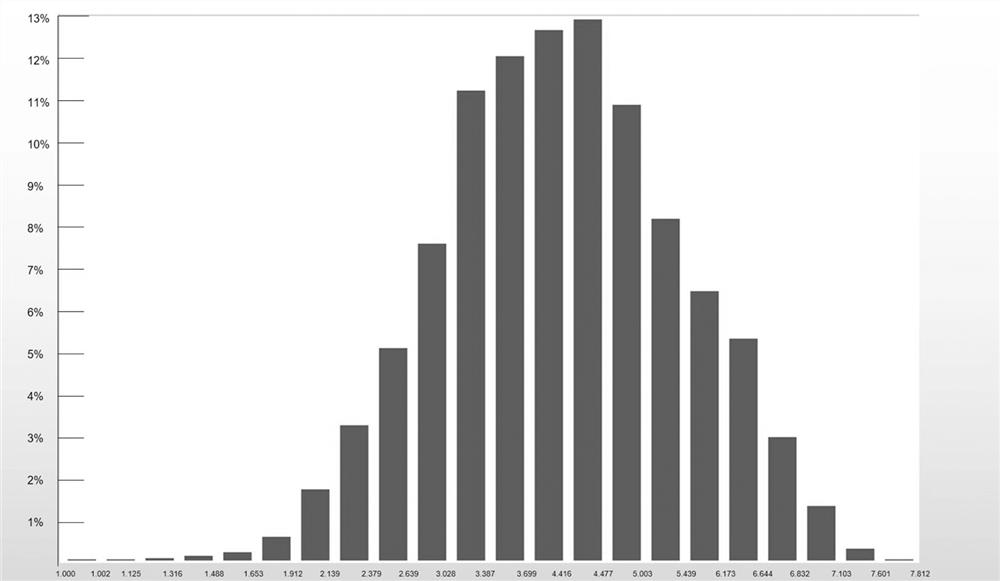

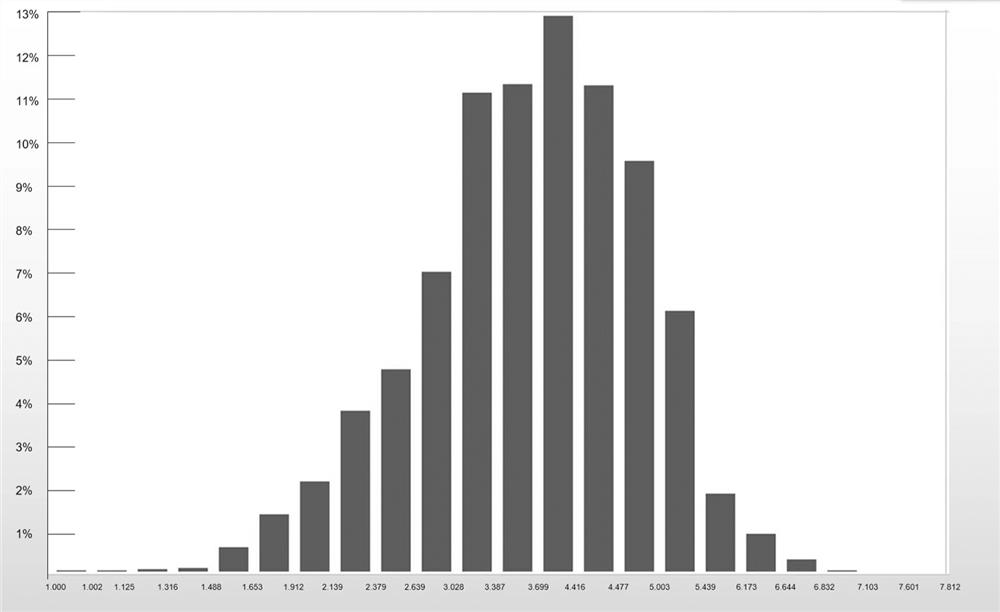

[0027] In the above-mentioned preparation method of the grinding liquid for silicon carbide wafer processing, the diamond micropowder is treated as follows: the diamond micropowder is taken in a dispersant and a suspending agent, water is added to form a two-phase mixture, and the two-phase medium density difference is used for centrifugal separation by centrifugation. The coarse-grained diamond micro-powder is removed separately to obtain the diamond micro-powder with a more concentrated particle size.

[0028] A preparation method of a grinding liquid for silicon carbide wafer processing, specifically comprising the following steps:

[0029] S1, take dispersant and suspending agent and mix, stir to obtain solution A;

[0030] S2, get diamond micropowder and add in solution A, make diamond micropowder disperse in solution A with ultrasonic-assisted pulse stirring, then add deionized water to obtain two-phase mixture A;

[0031] S3. Centrifuge the mixture A, so that the coars...

Embodiment 1

[0034] The diamond lapping liquid is composed of the following components in parts by mass: 0.5 part of diamond micropowder, 0.5 part of fatty acid polyethylene glycol ester, 1 part of oily suspending agent composed of peanut oil and sunflower oil, and 50 parts of deionized water.

[0035] Its preparation method is as follows:

[0036] S1, get the oil suspending agent that fatty acid polyethylene glycol ester is formed with peanut oil and sunflower oil, mix, stir to obtain solution A.

[0037] S2. Take diamond micropowder and add it to solution A, and disperse diamond micropowder in solution A with ultrasonic-assisted pulse stirring, and then add deionized water to obtain two-phase mixture A.

[0038] S3. When the stratification is clearly observed, start the centrifuge to perform multi-layer centrifugation on mixture A, and centrifuge the mixture at a speed of 4000 r / min for 5 minutes, so that the coarse-grained diamond micropowder enters the water phase for separation, and t...

Embodiment 2

[0042] The diamond grinding liquid is composed of the following components by mass: 5 parts of diamond micropowder, 5 parts of glycerol monostearate, 10 parts of sunflower oil oily suspending agent, and 75 parts of deionized water.

[0043] Its preparation method is as follows:

[0044] S1, get glycerol monostearate and mix with sunflower oil, stir to obtain solution A.

[0045] S2. Take diamond micropowder and add it to solution A, and disperse diamond micropowder in solution A with ultrasonic-assisted pulse stirring, and then add deionized water to obtain two-phase mixture A.

[0046] S3. When the stratification is clearly observed, start the centrifuge to perform multi-layer centrifugation on mixture A, and centrifuge the mixture at a speed of 5000r / min for 4 minutes, so that the coarse-grained diamond powder enters the water phase for separation. Coarse-grained diamond particles, the remaining diamond particles with a more concentrated particle size are in the oil phase, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com