Nylon 6/polypropylene composite material as well as preparation method and application thereof

A technology of composite material and polypropylene, which is applied in the field of nylon 6/polypropylene composite material and its preparation, can solve the problems of low paint adhesion and poor alcoholysis resistance, improve paint adhesion, improve alcoholysis resistance, The effect of excellent alcoholysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

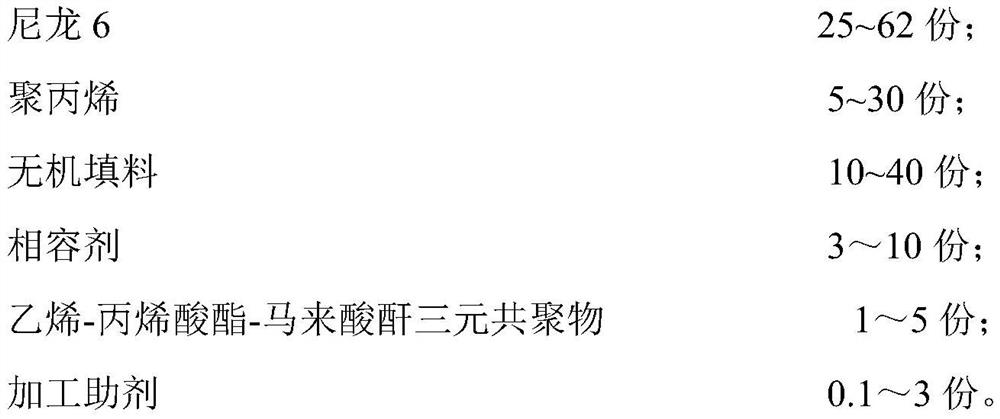

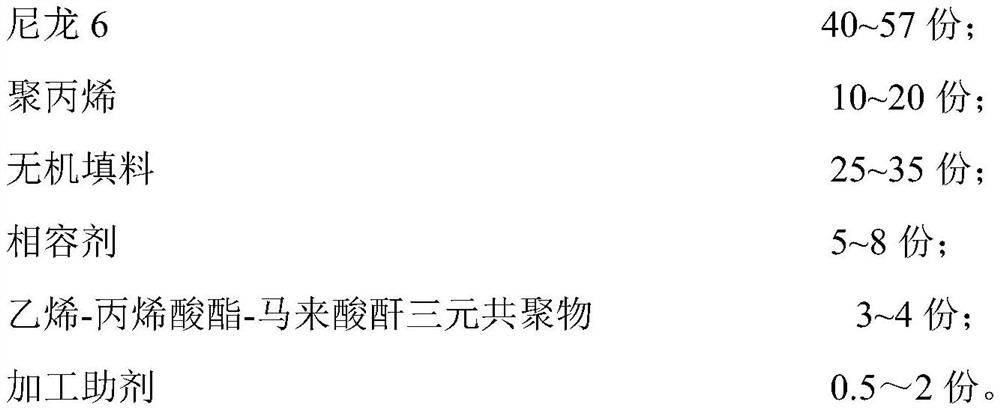

[0061] A nylon 6 / polypropylene composite material, in parts by weight, comprising the following components:

[0062] Nylon 6; polypropylene; inorganic filler; compatibilizer; ethylene-acrylate-maleic anhydride terpolymer; processing aid; processing aids are antioxidants and lubricants;

[0063] The specific content of each component is shown in Table 1 below.

[0064] The composition of nylon 6 / polypropylene composite material of each embodiment in Table 1 (in parts by weight)

[0065]

[0066] The preparation method of the above-mentioned nylon 6 / polypropylene composite material comprises the following steps:

[0067] The components are mixed uniformly, melted and extruded through a twin-screw extruder at 240-260° C., granulated, and dried to obtain the nylon 6 / polypropylene composite material.

Embodiment 7

[0069] A nylon 6 / polypropylene composite material, in parts by weight, comprising the following components:

[0070] Nylon 6; polypropylene; inorganic filler; compatibilizer; ethylene-acrylate-maleic anhydride terpolymer; processing aid; processing aids are antioxidants and lubricants;

[0071] Different from Example 1, the ethylene-acrylate-maleic anhydride terpolymer is ethylene-acrylate-maleic anhydride terpolymer 2.

[0072] The rest are the same as those in Embodiment 1, and are not repeated here.

Embodiment 8

[0074] A nylon 6 / polypropylene composite material, in parts by weight, comprising the following components:

[0075] Nylon 6; polypropylene; inorganic filler; compatibilizer; ethylene-acrylate-maleic anhydride terpolymer; processing aid; processing aids are antioxidants and lubricants;

[0076] Different from Example 1, the ethylene-acrylate-maleic anhydride terpolymer is ethylene-acrylate-maleic anhydride terpolymer 3.

[0077] The rest are the same as those in Embodiment 1, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com