Preparation method of pig thymosin

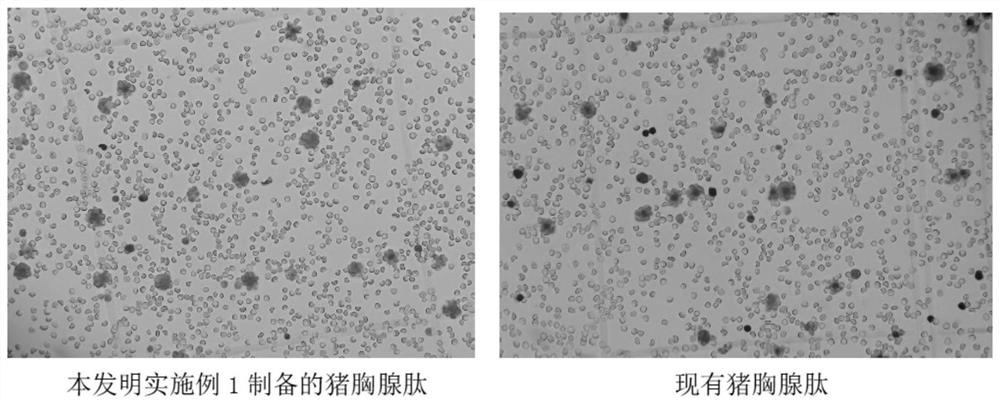

A technology of pig thymus and thymus, which is applied in the field of preparation of pig thymosin, can solve the problems of poor use efficiency of thymus, thymosin polypeptide structure, activity damage, limiting the application effect and use range of thymosin, and achieves the effect of improving the application effect and expanding the use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of porcine thymosin, comprising the following steps:

[0040] 1) Select the thymus of healthy pigs, porcine thymus is free of bovine viral diarrhea virus, porcine parvovirus, swine fever virus, porcine circovirus type 2, porcine reproductive and respiratory syndrome virus, foot-and-mouth disease virus, pseudorabies virus and African swine fever Virus contamination, remove the fascia, muscle, and adipose tissue on the surface of the pig thymus, wash it with water for injection, mince it by a meat grinder, mix the water for injection with the minced pig thymus, and homogenize it by a colloid mill to obtain a homogenate. ;

[0041] 2) The homogenate was broken by cells, incubated at 60° C. for 0.5 h in water, and then centrifuged to obtain centrifugation supernatant and centrifugation precipitate respectively. The centrifuged precipitate was further mixed with water for injection, homogenized by a colloid mill to obtain a homogenate, and the cells wer...

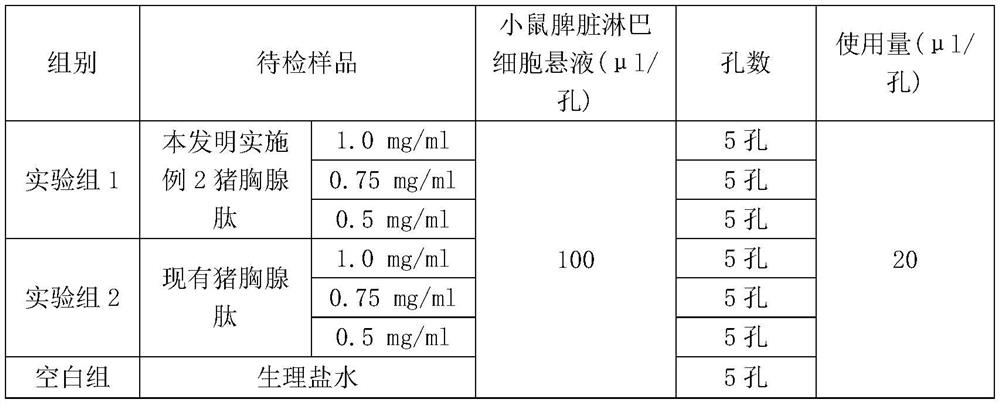

Embodiment 2

[0051] A preparation method of porcine thymosin, comprising the following steps:

[0052] 1) Select the thymus of healthy pigs, porcine thymus is free of bovine viral diarrhea virus, porcine parvovirus, swine fever virus, porcine circovirus type 2, porcine reproductive and respiratory syndrome virus, foot-and-mouth disease virus, pseudorabies virus and African swine fever Virus contamination, remove the fascia, muscle and adipose tissue on the surface of the porcine thymus, wash it with water for injection, mince it in a meat grinder, mix the water for injection with the pH value of 1.5 adjusted by hydrochloric acid and the minced porcine thymus, The homogenate was obtained by homogenizing with a colloid mill.

[0053] 2) The homogenate is subjected to cell fragmentation (repeated freeze-thaw fragmentation method), incubated at 60° C. in water for 2 hours, and then centrifuged to obtain centrifugation supernatant and centrifugation precipitate respectively. The centrifuged pr...

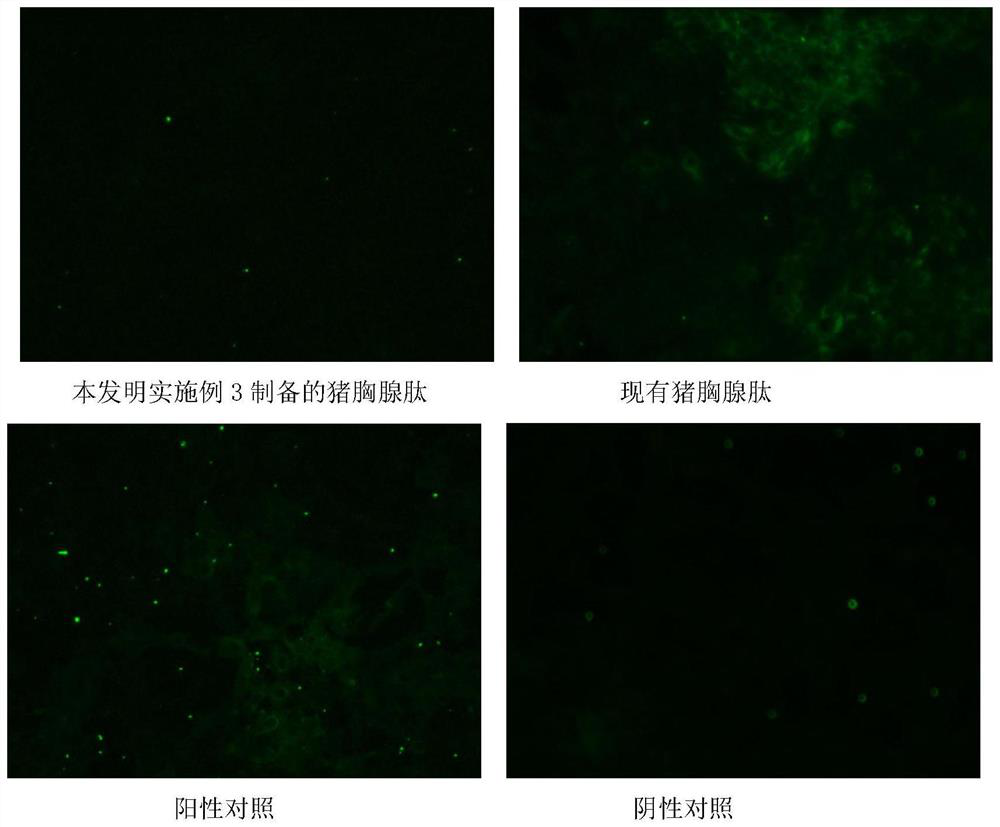

Embodiment 3

[0062] A preparation method of porcine thymosin, which comprises the following steps:

[0063]1) Select the thymus of healthy pigs, porcine thymus is free of bovine viral diarrhea virus, porcine parvovirus, swine fever virus, porcine circovirus type 2, porcine reproductive and respiratory syndrome virus, foot-and-mouth disease virus, pseudorabies virus and African swine fever Virus contamination, remove the fascia, muscle, and adipose tissue on the surface of the pig thymus, wash it with water for injection, mince it by a meat grinder, mix the water for injection with the minced pig thymus, and homogenize it by a colloid mill to obtain a homogenate. .

[0064] 2) The homogenate was broken by cells, incubated at 60° C. for 1 h, and then centrifuged to obtain centrifugation supernatant and centrifugation precipitate, respectively. The centrifuged precipitate was further mixed with water for injection adjusted to pH 2.0 by hydrochloric acid, homogenized by a colloid mill to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com