Wastewater reduction method combining hyperbolic tower and mechanical atomization evaporator

A mechanical atomization and evaporator technology, applied in chemical instruments and methods, animal husbandry wastewater treatment, food industry wastewater treatment, etc. Small footprint, improved evaporation efficiency, and less construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

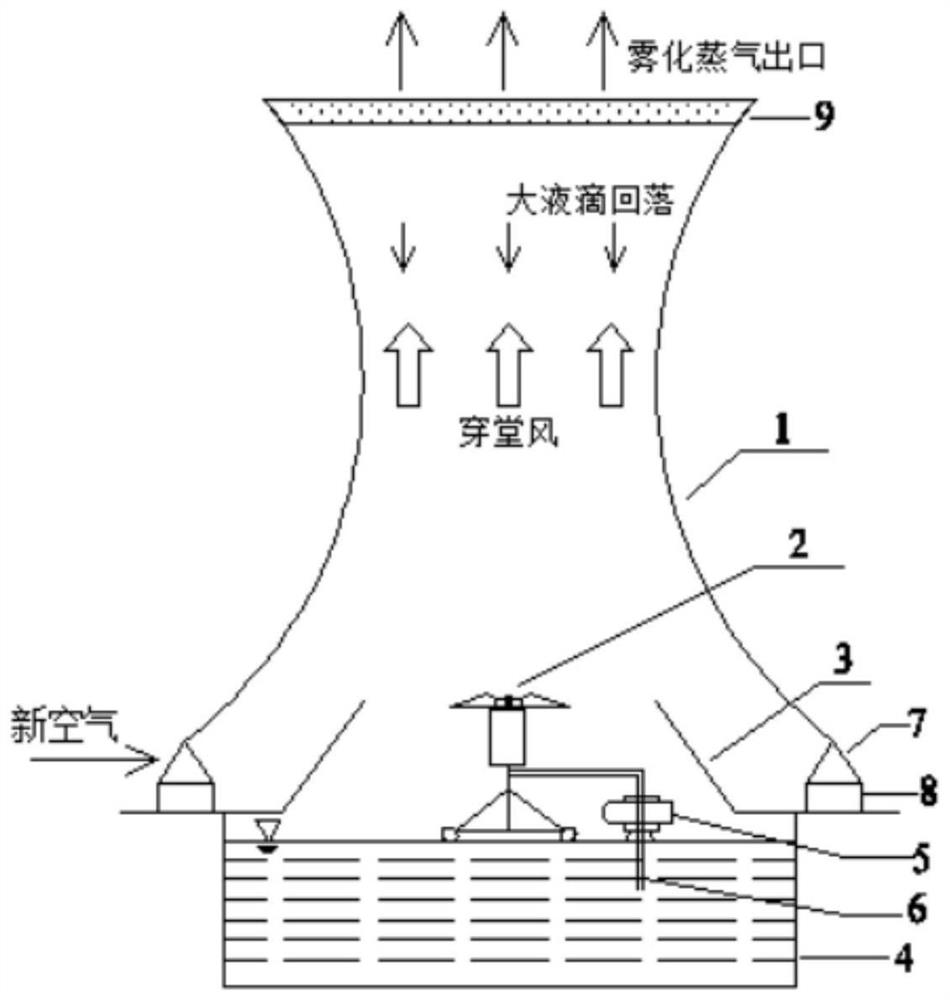

[0057] The method for reducing the amount of waste water in combination with a hyperbolic tower and a mechanical atomization evaporator according to the present invention is realized based on a waste water reduction device; such as figure 1 As shown, the device includes: a waste water tank 4 with a circular cross-section; a support base 8 arranged around the edge of the waste water tank 4; a support frame 7 fixed on the support base 8 and assembled from a plurality of single components The hyperbolic tower 1 is a hollow structure with a top and bottom opening composed of a lower ring beam, a cylinder wall and a top rigid ring, and the side edges of its axial section are in a symmetrical hyperbolic shape; the lower ring beam is fixed and installed On the support frame 7, there is a gap as the air inlet between the bottom of the hyperbolic tow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com